Automobile front automobile body frame component

A car body frame and automobile technology, which is applied in the connection between the car body and the frame, vehicle components, upper structure, etc. It can solve the problems of restricted cavity size, unfavorable collision performance of the foot pedal installation area, and affecting the welding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

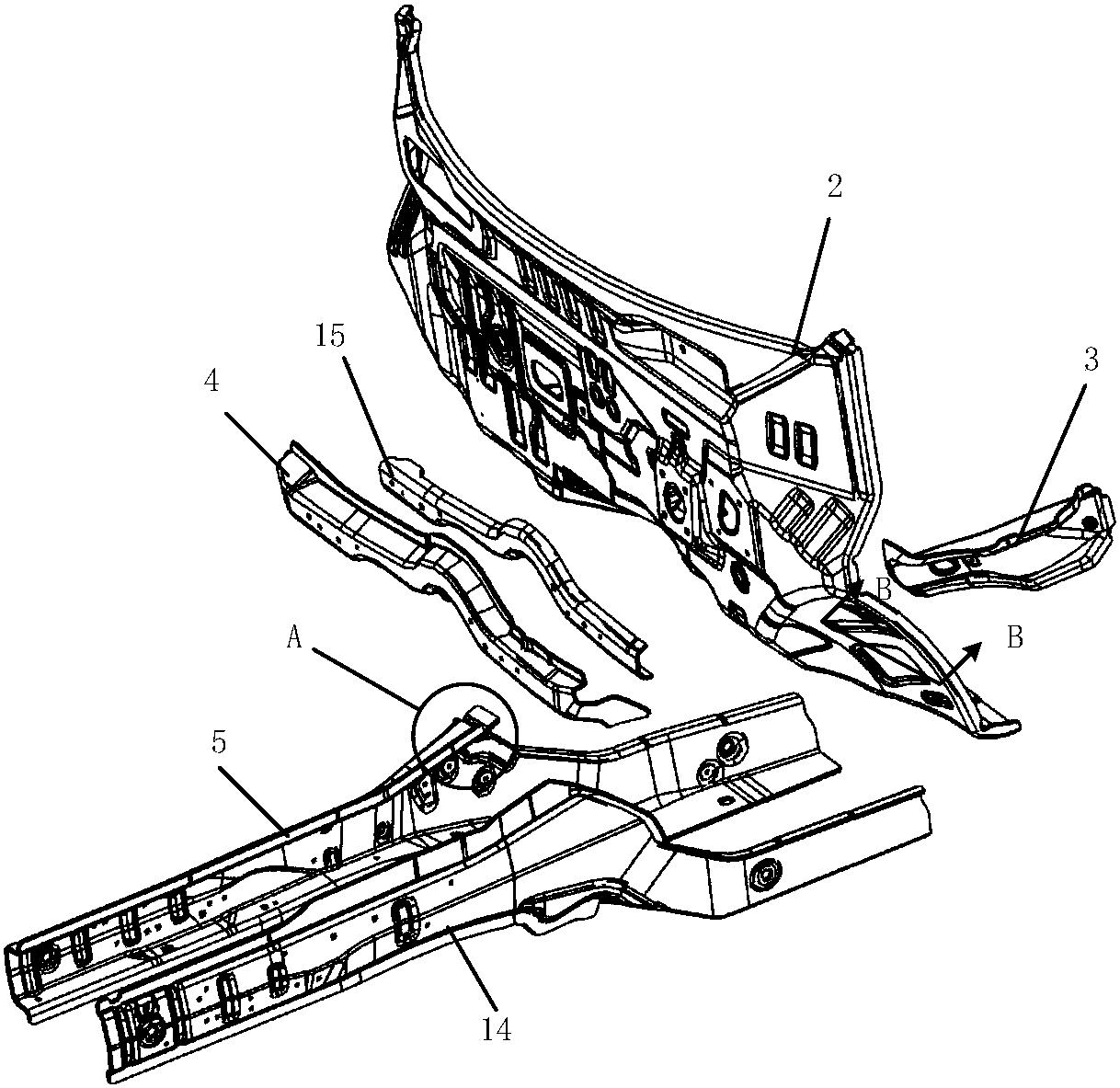

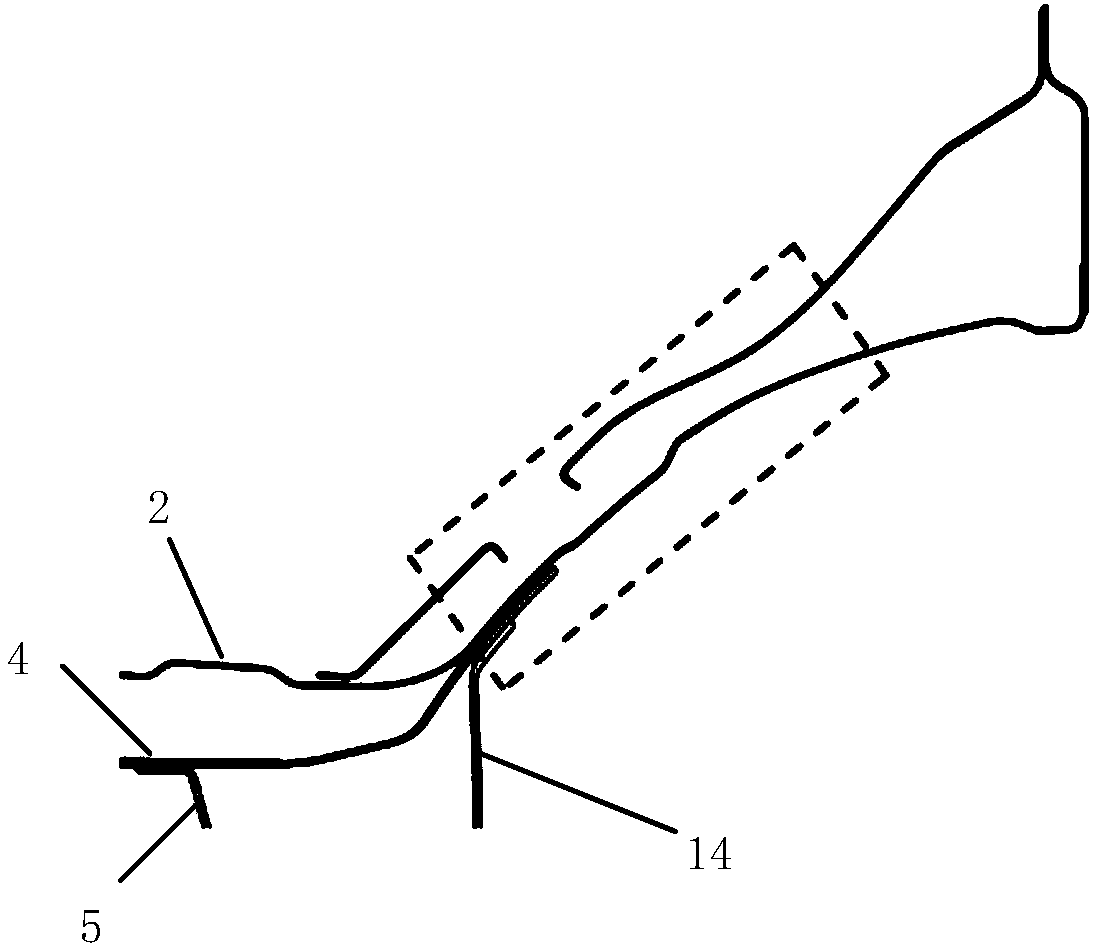

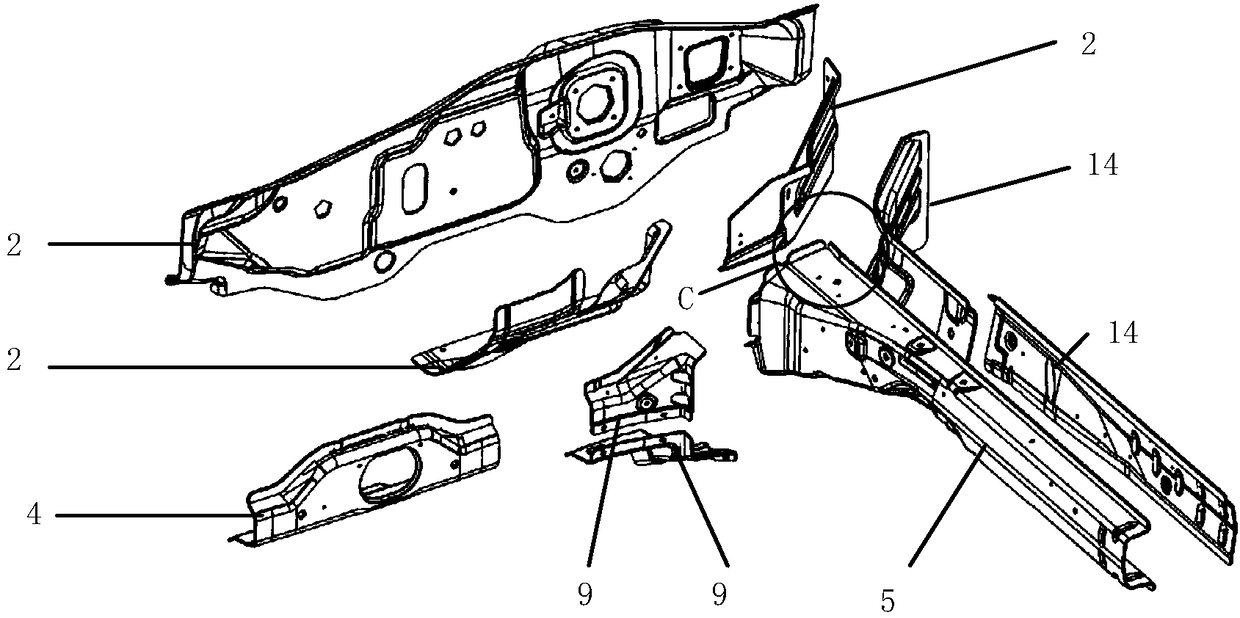

[0039] The following with attached Figure 8 to Figure 17 A car front body frame assembly of the present invention is further described in detail.

[0040] A kind of automobile front body frame assembly of the present invention, please refer to Figure 8-17, comprising a front anti-collision beam 1, a dash panel 2, a dash panel reinforcing plate 3, a front beam 4 and a front beam 5, the dash panel 2 is fixed on the rear portion of the front cross beam 4, and the dash panel reinforces The panel 3 is located at the rear of both ends of the dash panel 2, the dash panel reinforcement plate 3 is fixedly connected with the dash panel 2 to form a dash panel cavity 6, and the left and right ends of the front beam 4 are connected to the dash panel The left and right ends of the dash panel 2 are fixedly connected to form a closed cross beam cavity 7, the cross beam cavity 7 corresponds to the front and rear positions of the dash panel cavity 6, and the rear end of the front frame 5 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com