Production process of iron ion graphene based on multiphase quantum self-coupling reaction

A production process, phase quantum technology, applied in the field of iron ion graphene production process, can solve the problems of serious emissions, high energy consumption, etc., and achieve the effect of complete crystal lattice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

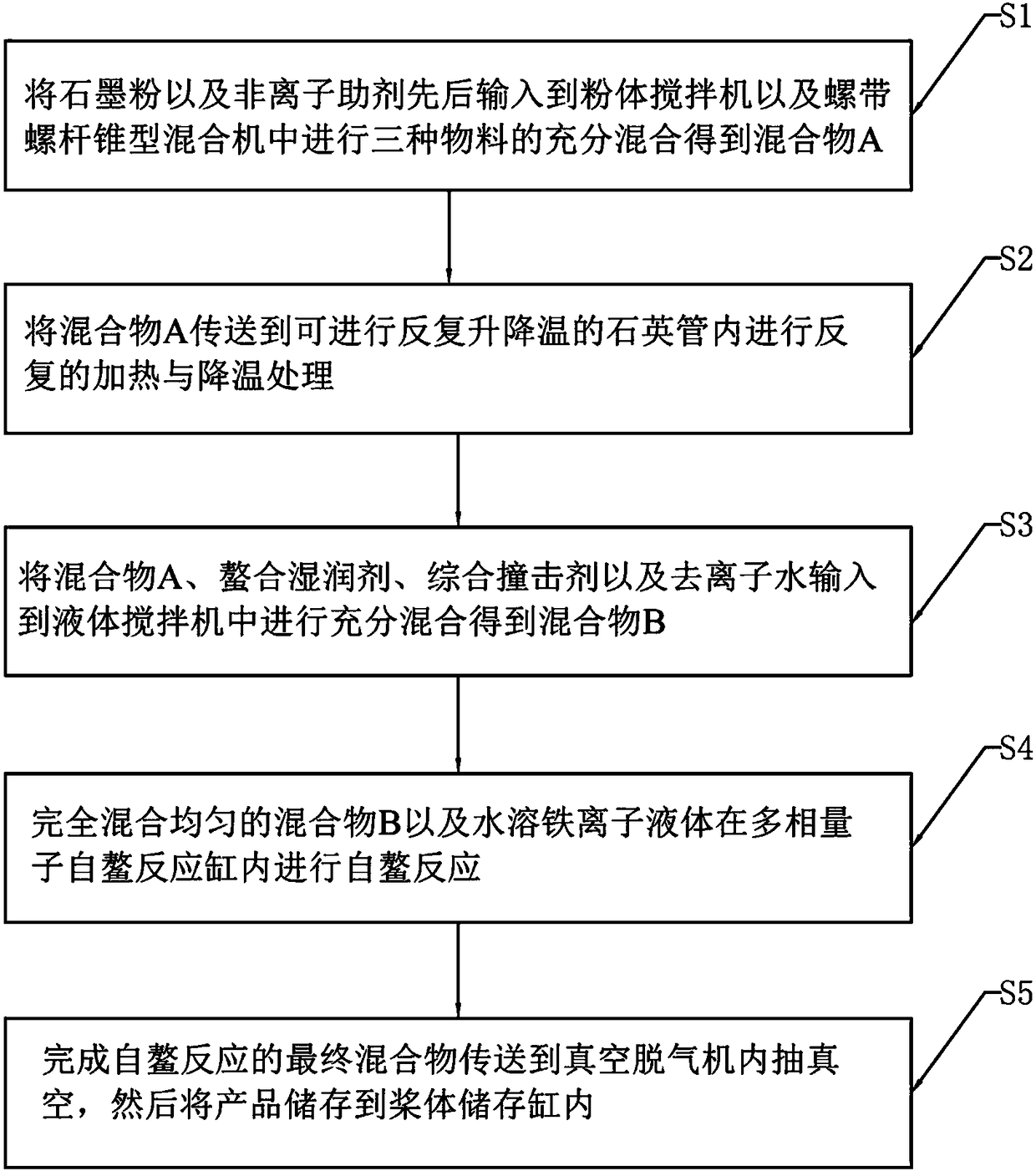

[0025] refer to figure 1 , a kind of ferric ion graphene production technology based on heterogeneous quantum self-coupling reaction of the present invention, comprises the following steps:

[0026] S1. Feeding and mixing, input graphite powder and non-ionic additives successively into powder mixer and ribbon-screw-cone mixer to fully mix the three materials to obtain mixture A; the speed of powder mixer is 100-5000r / min, the stirring time is 10min; the stirring power of the ribbon-screw-conical mixer is 0.4kW / kg, and the stirring time is 20min;

[0027] S2. Preliminary reaction, transfer the mixture A to a quartz tube that can be repeatedly heated and cooled for repeated heating and cooling; the quartz tube is connected to the heating device and a low-temperature refrigerator to control the temperature rise and fall; the mixture A, a chelating wetting agent , The mass ratio of comprehensive impact agent and deionized water is 100000:1:1000:2000:100;

[0028] S3, further mi...

no. 2 example

[0032] A kind of ferric ion graphene production process based on heterogeneous quantum self-coupling reaction of the present invention comprises the following steps:

[0033] S1. Feeding and mixing, input graphite powder and non-ionic additives successively into powder mixer and ribbon-screw-cone mixer to fully mix the three materials to obtain mixture A; the speed of powder mixer is 100-5000r / min, the stirring time is 10min; the stirring power of the ribbon-screw-conical mixer is 0.4kW / kg, and the stirring time is 20min;

[0034] S2. Preliminary reaction, transfer the mixture A to a quartz tube that can be repeatedly heated and cooled for repeated heating and cooling; the quartz tube is connected to the heating device and a low-temperature refrigerator to control the temperature rise and fall; the mixture A, a chelating wetting agent , The mass ratio of comprehensive impact agent and deionized water is 100000:5:40000:2000:50000;

[0035] S3, further mixing, the mixture A, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com