Bus suction-resisting bracket

A suction support and busbar technology, applied in the field of busbar anti-suction support, can solve problems such as loose connection between busbar post insulators and busbar support bolts, busbar tipping, and electrolyzer interruption of power supply, etc., so as to achieve a firm overall structure and good use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

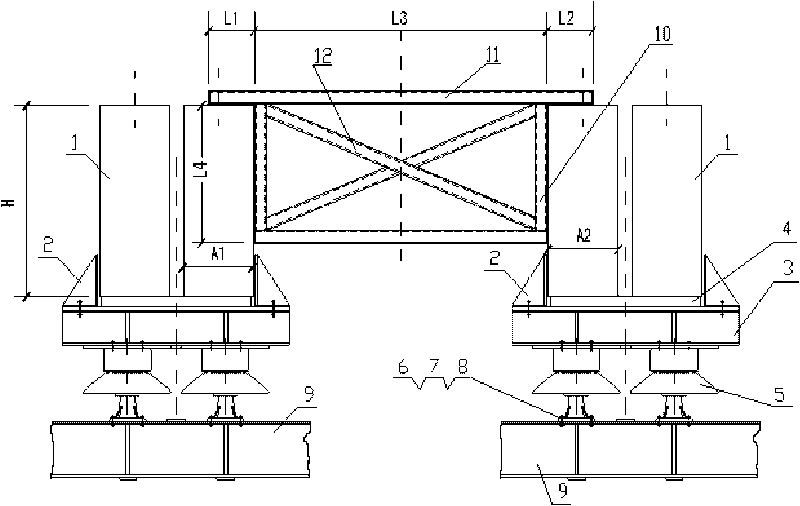

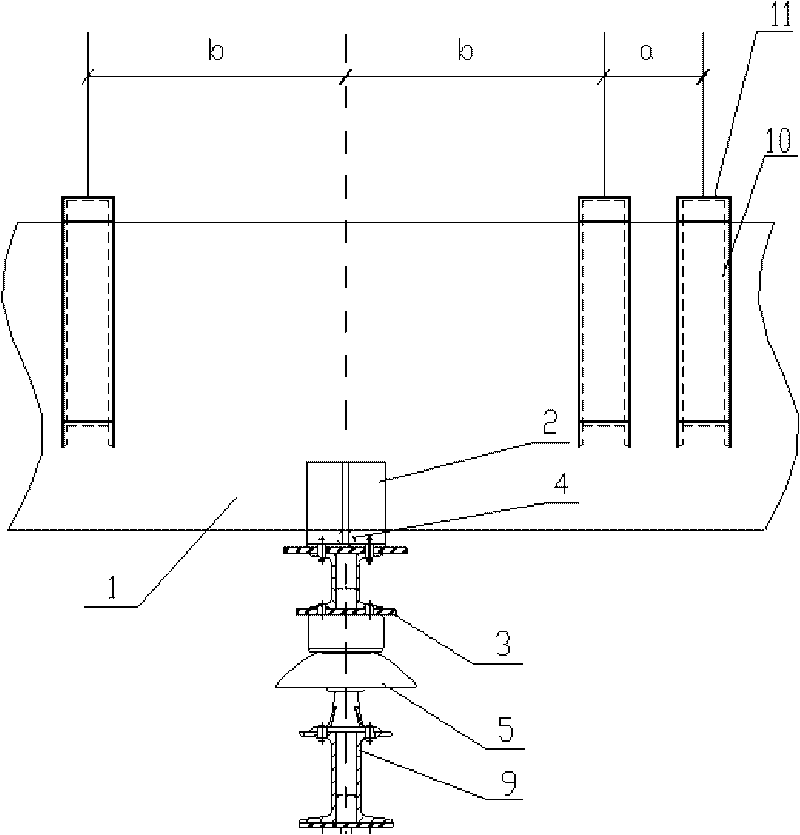

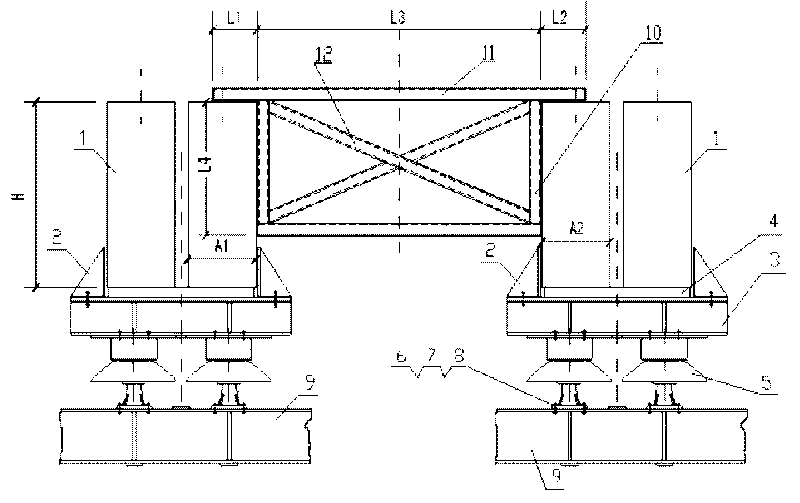

[0015] Embodiment of the present invention: it includes DC large busbar 1, plywood 2, base bracket 3, etc., there is a post insulator 5 under the base bracket 3, and the post insulator 5 is connected to the channel steel 9 through bolts 6, nuts 7, and washers 8, There are rolling bars 4 and splints 2 on the base bracket 3, and the DC large busbar 1 is placed on the rolling bar 4 and inside the splint 2; anti-suction brackets 10 are set between the inner DC large busbars 1; the anti-suction brackets 10 are Frame structure, welded with channel steel, with fork support 12 inside, the length of the top arm 11 is L1+L2+L3, which is greater than the distance L3 between the bus bars, and the left and right ends of the arms overlapped with the top of the bus bar The lengths L1 and L2 are not less than half of the thickness of the overlapped busbars, namely the thicknesses A1 and A2 of the left and right busbars; the length L4 of the anti-suction support under the lap arm is not less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com