A kind of preparation method of chitosan-poly 2-acrylamido-2-methylpropanesulfonate sodium copolymer used for monocrystalline silicon wool

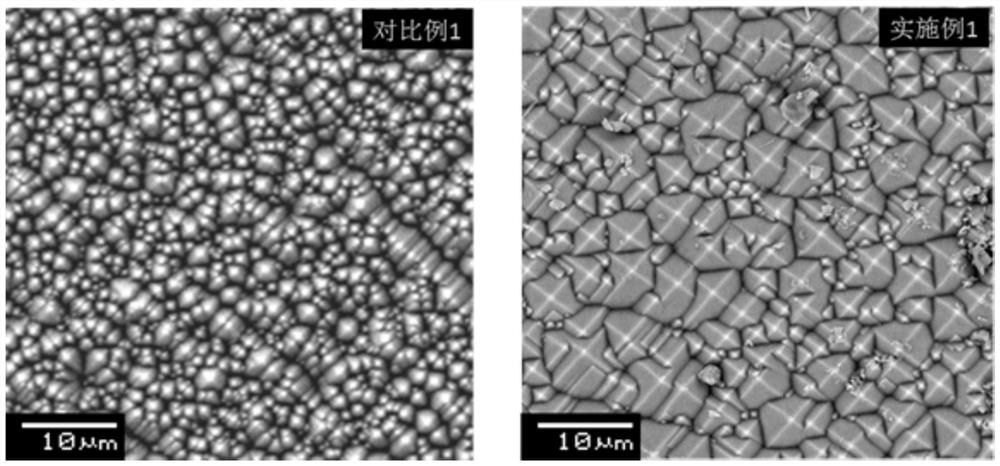

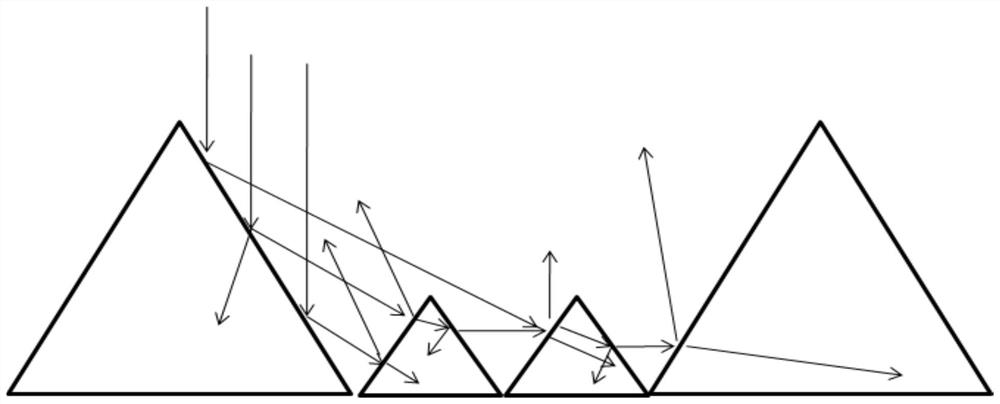

A technology of sodium methylpropanesulfonate and acrylamide, which is applied in the field of preparation of chitosan-poly 2-acrylamide-2-sodium methylpropanesulfonate copolymer, can solve the problem that chitosan cannot be used, It can achieve the effect of uniform four-sided pyramid on the single crystal silicon wafer, low reflectivity, and improved deposition ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of chitosan-poly 2-acrylamide-2-methylpropanesulfonate sodium copolymer: 10g of chitosan with a molecular weight of 30000 and a degree of deacetylation of 54% was dissolved in 500mL of deionized water and placed under nitrogen protection Next, add 10g cerium ammonium nitrate and 30g sodium 2-acrylamido-2-methylpropanesulfonate successively; raise the temperature to 60°C, react for 6h, then place the reaction system in a dialysis bag with a molecular weight cut-off of 15000Da, and remove After dialysis in deionized water for 3 days, the copolymer was collected by lyophilization.

[0039] Preparation of texturing additives: 2.5% chitosan-poly 2-acrylamide-2-methylpropanesulfonate sodium copolymer, 0.5% methylglycinediacetic acid sodium, 3-methoxy-3- Dissolve 5% methyl-1-butanol and 0.1% phenoxyethanol in the remaining water and mix well.

[0040] Preparation of texturing liquid: add the above-mentioned prepared texturing additive to the alkaline solution and ...

Embodiment 2

[0043] Preparation of chitosan-poly 2-acrylamido-2-methyl propane sulfonate copolymer: 5g of chitosan with a molecular weight of 50,000 and a degree of deacetylation of 55% was dissolved in 500mL of deionized water, Under protection, 6g of cerium ammonium nitrate and 25g of sodium 2-acrylamido-2-methylpropanesulfonate were added successively; the temperature was raised to 50°C and reacted for 4h, and then the reaction system was placed in a dialysis bag with a molecular weight cut-off of 20,000Da, After dialysis in deionized water for 5 days, the copolymer was collected by lyophilization.

[0044] Preparation of texturizing additives: 1.5% chitosan-poly 2-acrylamide-2-methylpropanesulfonate sodium copolymer, 1.0% methyl glycine diacetate sodium, 3-methoxy-3- Dissolve 10% methyl-1-butanol and 0.05% phenoxyethanol in the remaining water, and mix well.

[0045] Preparation of texturing liquid: add the above-mentioned prepared texturing additive to the alkaline solution, and mix ...

Embodiment 3

[0048] Preparation of chitosan-poly 2-acrylamido-2-methyl propane sulfonate copolymer: 15g of chitosan with a molecular weight of 10000 and a degree of deacetylation of 52% was dissolved in 500mL of deionized water and heated in helium Under protection, 6g of cerium ammonium nitrate and 15g of sodium 2-acrylamido-2-methylpropanesulfonate were added successively; the temperature was raised to 80°C, and the reaction was carried out for 24 hours. After dialysis in deionized water for 2 days, the copolymer was collected by lyophilization.

[0049] Preparation of texturizing additives: 5% of the above-mentioned chitosan-poly 2-acrylamido-2-methylpropanesulfonate sodium copolymer, 0.1% of sodium methylglycinediacetate, 3-methylpropanediacetate in a certain mass percentage 5% of oxy-3-methyl-1-butanol and 0.5% of phenoxyethanol were dissolved in the rest of the water and mixed evenly.

[0050] Preparation of texturing solution: add the above-mentioned prepared texturing additive to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com