Double-furnace alternate continuous smelting system

A melting furnace and main control cabinet technology, applied in the direction of furnace, furnace type, AC network circuit, etc., can solve the problems of high equipment investment cost, low smelting efficiency, poor performance of anti-electromagnetic interference, etc., and achieve low cost, anti-electromagnetic Good interference performance and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

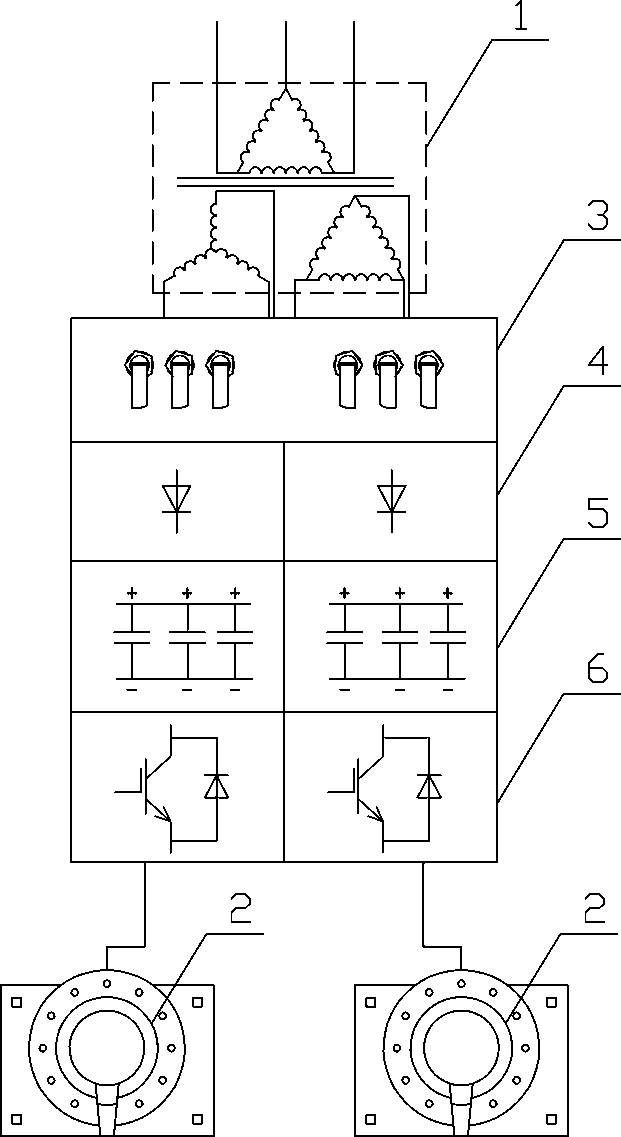

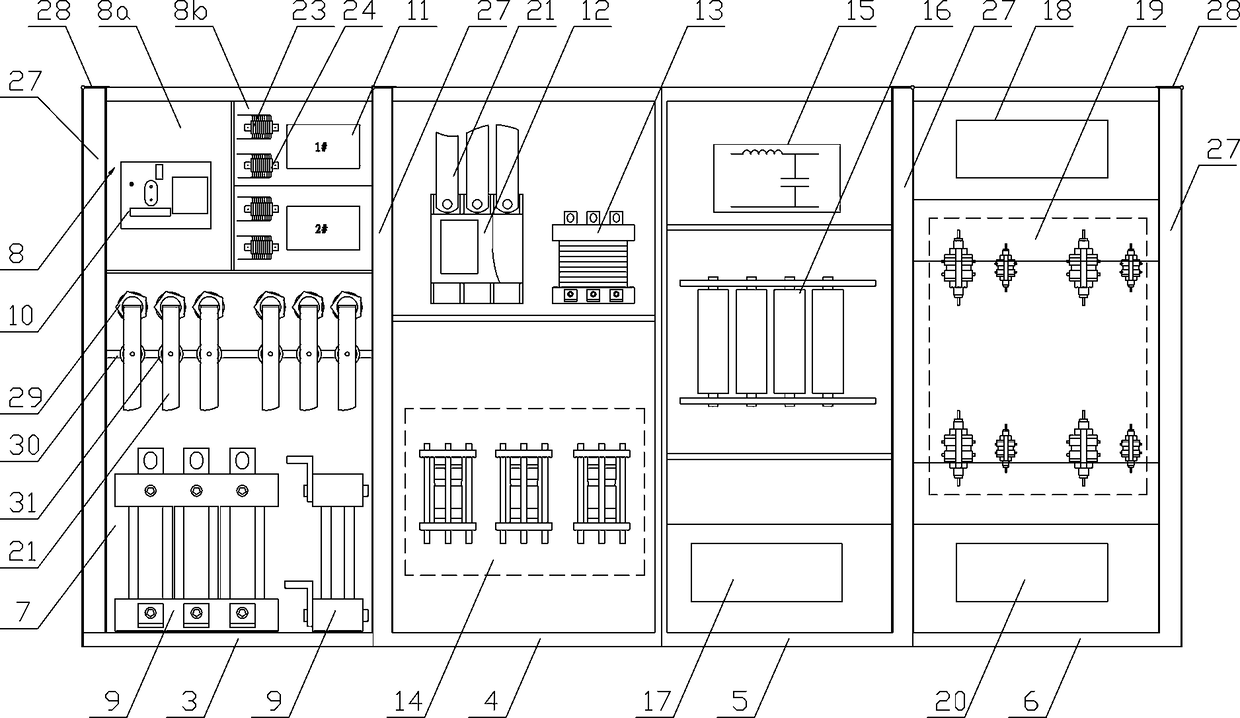

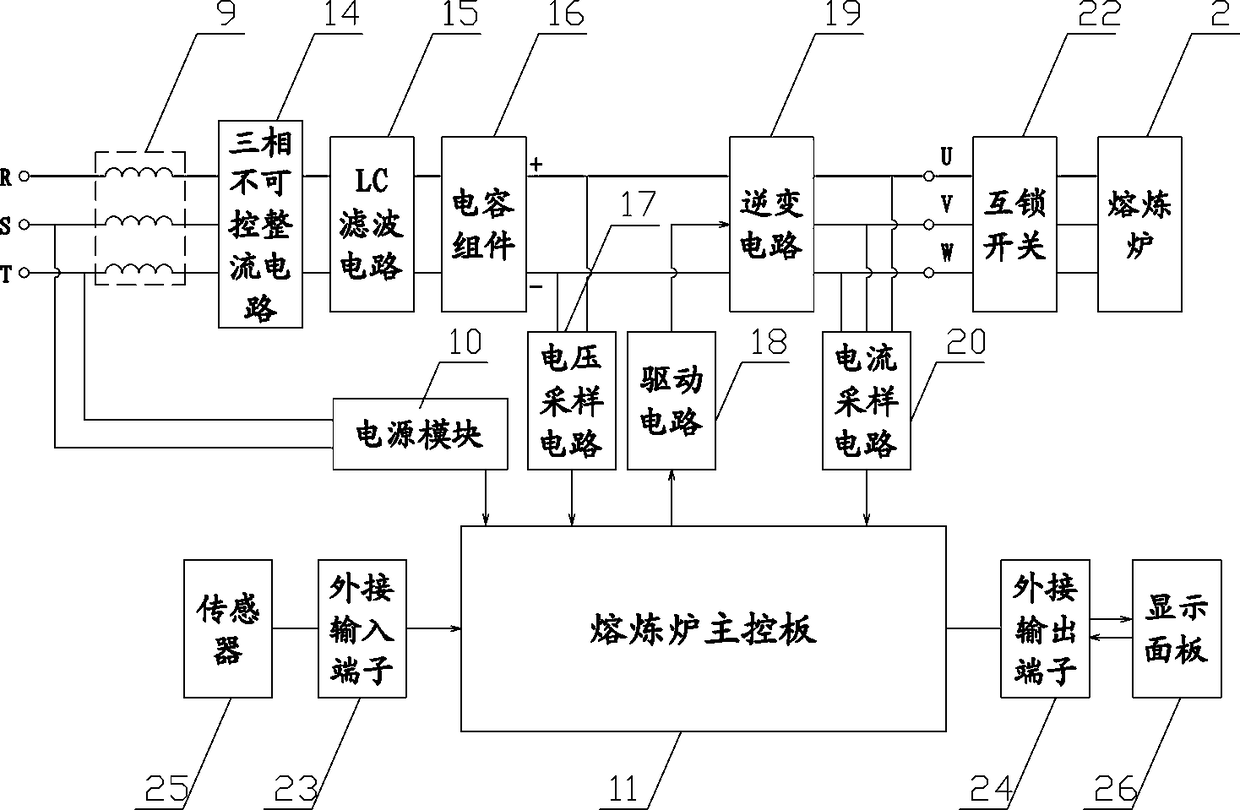

[0014] see Figure 1-3 , a dual-furnace alternate continuous smelting system, comprising a primary transformer 1, two melting furnaces 2, a main control cabinet 3, and a rectifier cabinet 4, a capacitor cabinet 5, and an inverter cabinet 6 matched with each melting furnace; The main control cabinet 3 is provided with a high-voltage chamber 7 and a low-voltage chamber 8. In the high-voltage chamber 7, there are two reactors 9. In the low-voltage chamber 8, a power module 10 and two corresponding to the two melting furnaces 2 are respectively arranged. Block smelting furnace main control panel 11; circuit breaker 12, secondary transformer 13 and three-phase uncontrollable rectification circuit 14 are provided in rectifier cabinet 4; LC filter circuit 15, capacitor assembly 16 and voltage sampling are provided in capacitor cabinet 5 Circuit 17; a drive circuit 18, an inverter circuit 19 and a current sampling circuit 20 are provided in the inverter cabinet 6.

[0015] see figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com