Spraying linkage integrated dust falling system used for coal mine underground fully mechanized coal mining face

A fully-mechanized mining face and linkage technology, applied in dust prevention, mining equipment, earthwork drilling and mining, etc., can solve the problem that the infrared emitting and receiving devices are easily affected by the outside world, cannot normally open the fully-mechanized mining support frame to spray, and cannot realize Automatic spraying and other issues to achieve the effect of improving the efficiency of water mist dust reduction, avoiding dust scattering, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

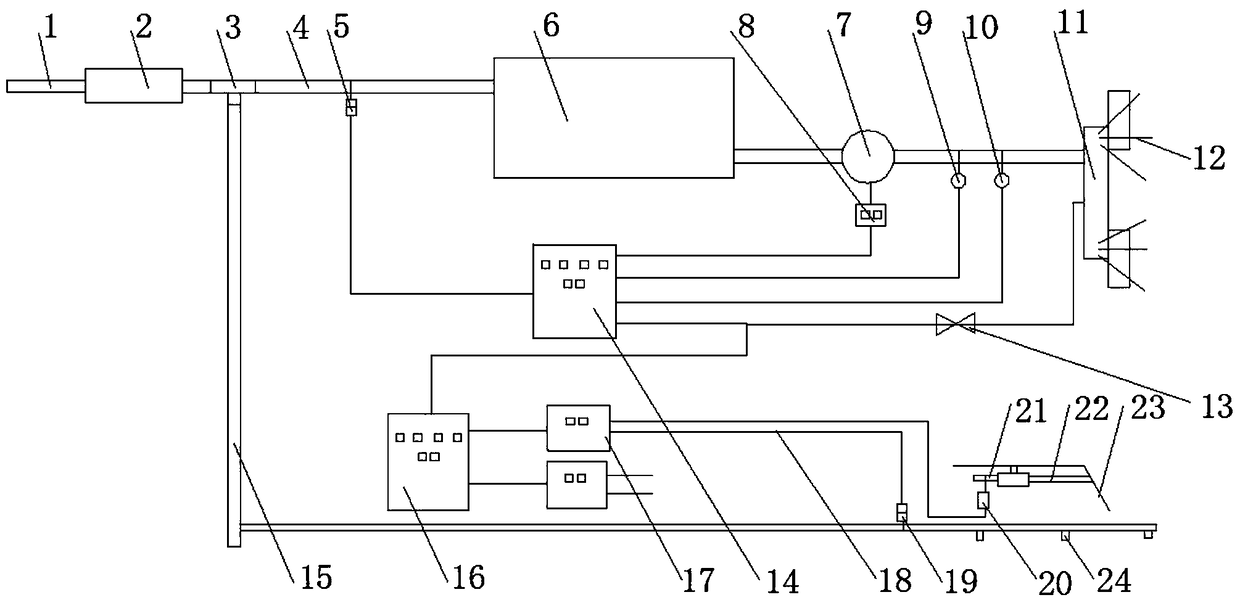

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] Such as figure 1 As shown, a spray linkage integrated dust suppression system for fully mechanized coal mining working faces in underground coal mines includes a water inlet pipe 1, which is connected to one end of a tee 3 through a water quality filter 2, and the other two ports of the tee 3 are respectively connected to One end of the shearer spray water supply pipeline 4 of the shearer internal and external spray control system, and one end of the fully mechanized mining support frame water inlet pipe 15 of the hydraulic fully mechanized mining support frame spray control system; the internal and external spraying of the coal shearer The control system includes solenoid valve Ⅰ5, water tank 6, high-pressure pump 7, frequency conversion power switch 8, water pressure sensor 9, flow sensor 10, power start valve 13, signal integrator Ⅰ14, internal and external sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com