Advanced wastewater treatment process where hydrostatic and hydrodynamic principle is applied

An advanced treatment and kinetic technology, applied in multi-stage water treatment, biological water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problem of ineffective treatment and utilization of waste residue, low utilization rate of waste water and residue, and difficult waste water. Advanced treatment and other problems, to achieve the effect of removing soluble solids, eliminating secondary pollution, and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

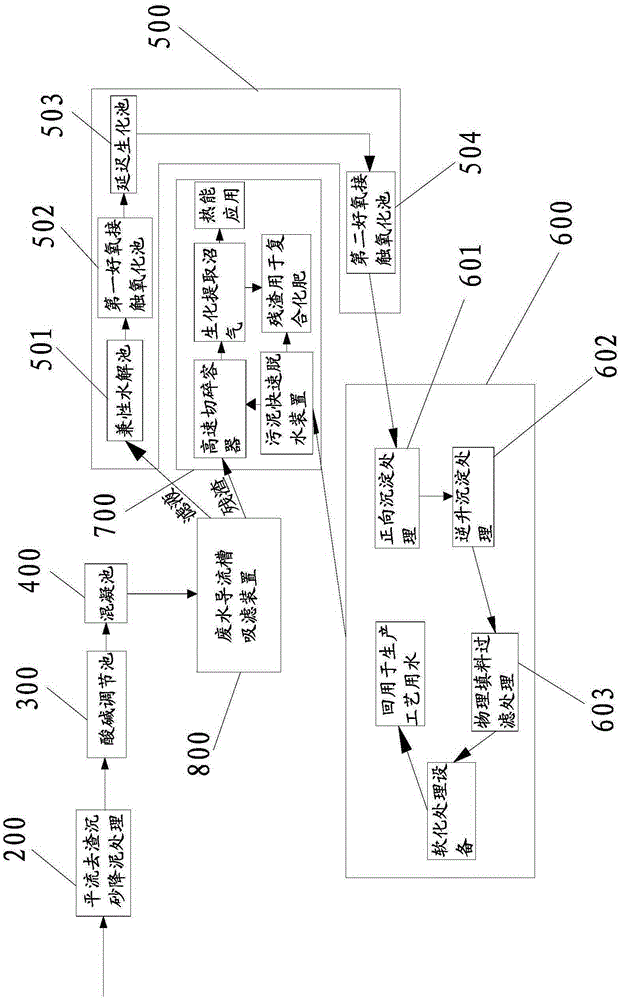

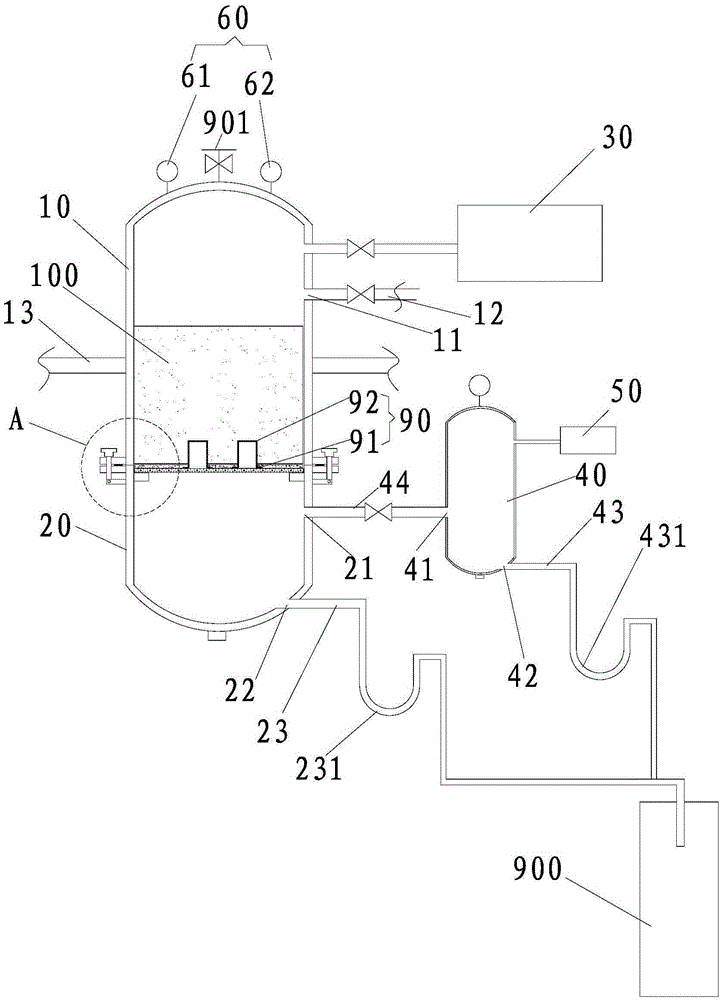

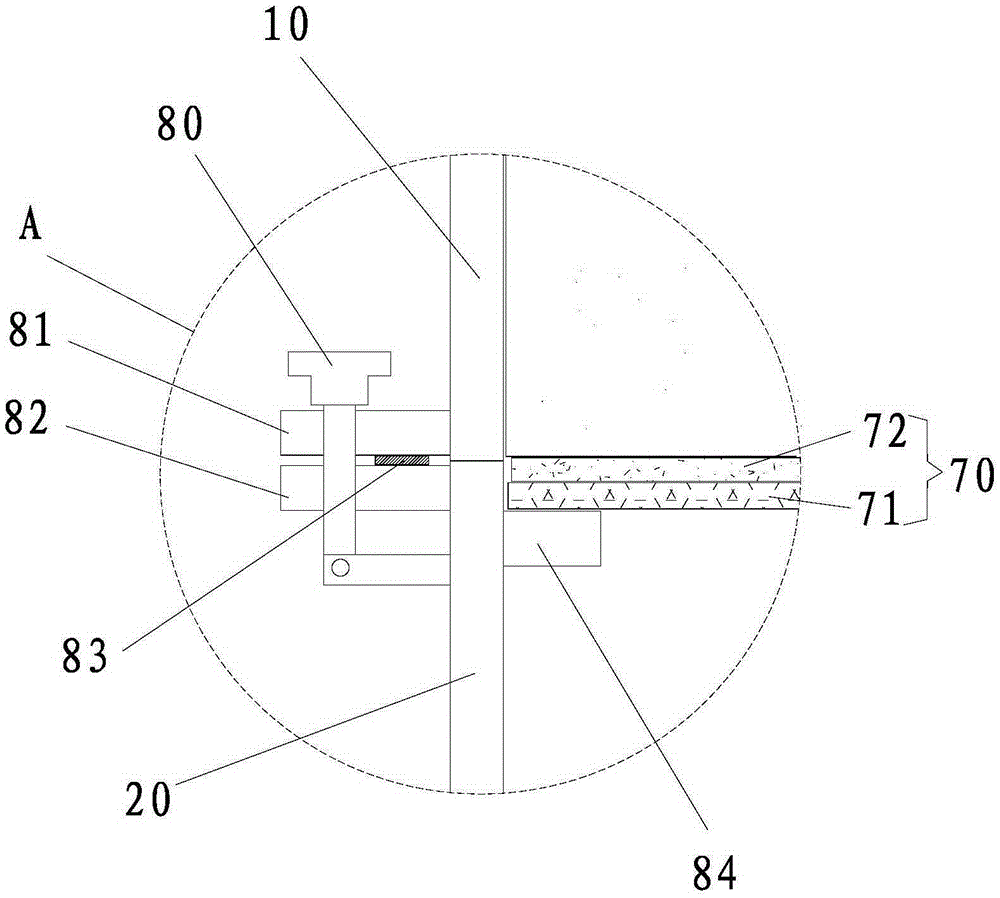

[0062] refer to Figure 1 to Figure 3 , an advanced wastewater treatment process that applies the principles of liquid static and dynamics, including advection deslagging, sanding, and mud reduction treatment 200 for particulate matter and suspended matter in wastewater, and advection deslagging, sanding, and mud reduction treatment 200. The treated wastewater is sent to acid The alkali adjustment tank 300 performs acid-base adjustment treatment, the acid-base adjustment treated wastewater is input into the coagulation tank 400 for coagulation treatment, and the coagulated wastewater is sent to the wastewater diversion tank suction filtration device 800 for suction filtration treatment, The suction and filtration device 800 of the waste water diversion tank is at a high position, and the wastewater treated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com