Fuel gas pipeline internal detection method

A detection method and technology for gas pipelines, which are applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as increasing transportation energy consumption, affecting pipeline transportation efficiency and safety, and increasing pipeline friction, achieving data High detection accuracy, good for maintenance and enhanced safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

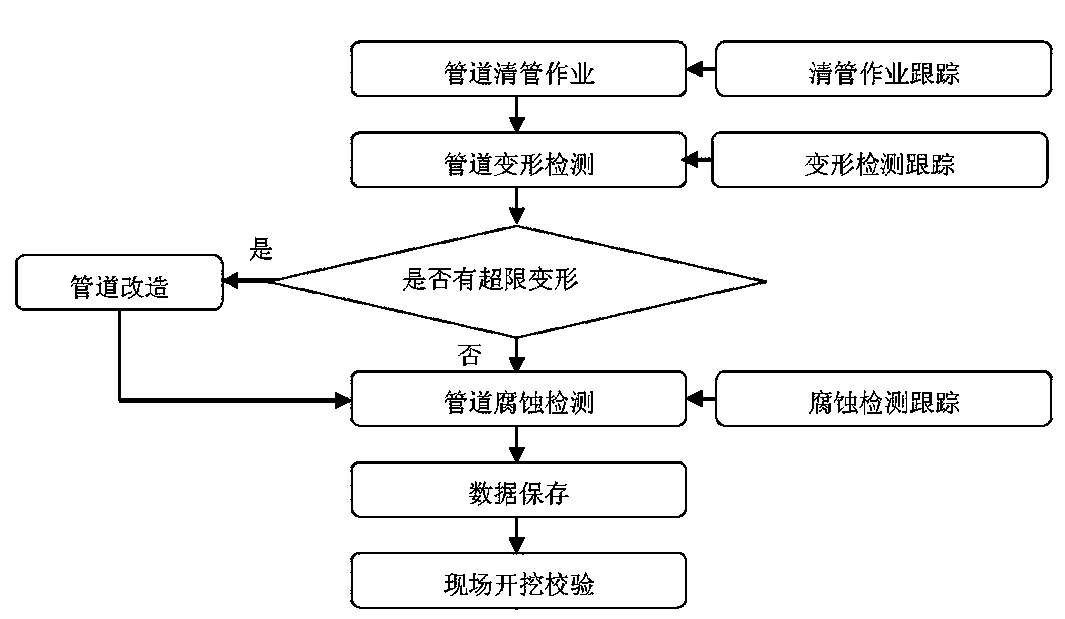

[0022] as attached figure 1 As shown, the present invention discloses a detection method in a gas pipeline, which directly detects the buried natural gas pipeline without digging up the soil to expose the pipeline. The method includes the following steps:

[0023] Perform pigging operations on buried pipelines to remove impurities and foreign matter in the pipelines. Cleaning is usually carried out in the pipeline with a washer. Foam pigs, straight dish mixed caliper pigs, steel brush pigs and magnetic pigs can be used. According to the characteristics of different pigs, they can be used in stages, and the pipelines can be pigged step by step. Impurities in the pipeline. During the pigging operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com