A device for quantitatively filling fireworks balls

A technology of fireworks bombs and bright beads, which is applied in the direction of offensive equipment, pyrotechnics, weapon types, etc., can solve the problem of restricting the production capacity of spherical fireworks bomb production enterprises, the improvement of product quality and production safety, and the difficulty in product quality and production safety. Problems such as the development of the spherical fireworks shell industry, to achieve the effects of single-body controllable dose, protection of personal and property safety, and overall structure and material safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

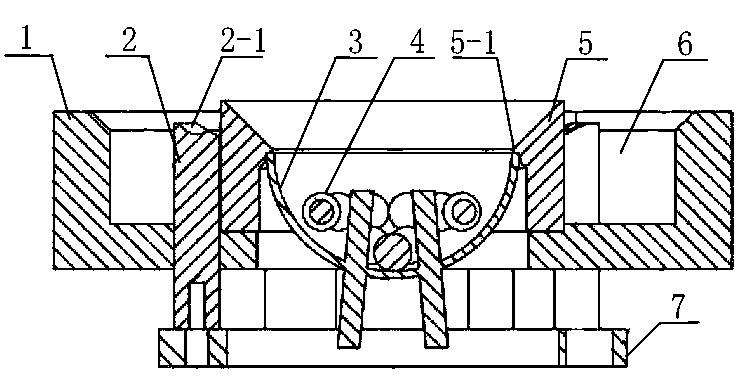

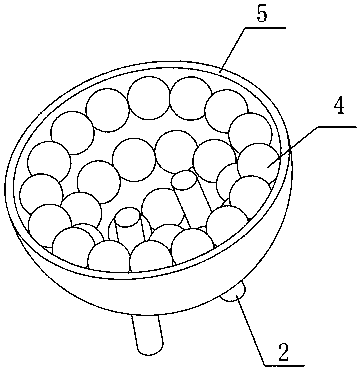

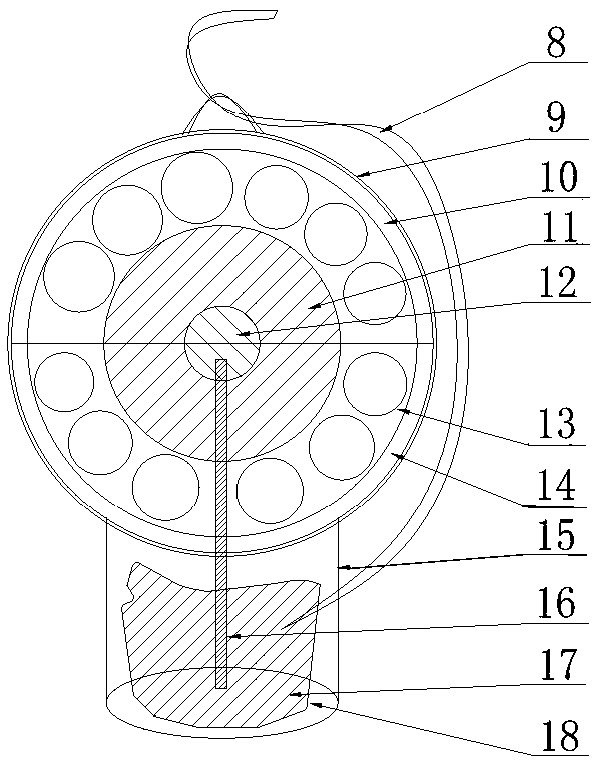

[0017] The device of quantitatively filling the bright pearls of fireworks in the present embodiment, such as figure 1 As shown, it includes a fixed frame 1 with a silo 6, an ejector rod 2, an ejector rod fixed block 7 and a jacking mechanism. In this embodiment, a hydraulic cylinder is used as the jacking mechanism, and the jacking mechanism and the ejector rod fixed block 7 connections. The fixing frame 1 is provided with a positioning block 5 , the inner wall of the positioning block 5 is provided with a hook structure 5 - 1 , and the upper end surface of the spherical shell 3 is engaged with the hook structure 5 - 1 to limit the position of the spherical shell 3 . In this embodiment, the spherical shell 3 is divided into an upper spherical shell and a lower spherical shell, and the two hemispherical shells are buckled together to form the spherical shell 3 . A bright bead 4 is arranged in the feed bin 6, and one end of the ejector rod 2 is connected with a jacking mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com