Device for measuring high temperature and high pressure transport properties based on diamond opposed anvils

A diamond anvil, high temperature and high pressure technology, applied in the direction of material resistance, material thermal development, etc., can solve the problems of high experimental equipment requirements, complex experimental technology, large temperature measurement error, etc., to reduce the difficulty of experimental operation and widen the experiment. The effect of operating space and avoiding partial short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

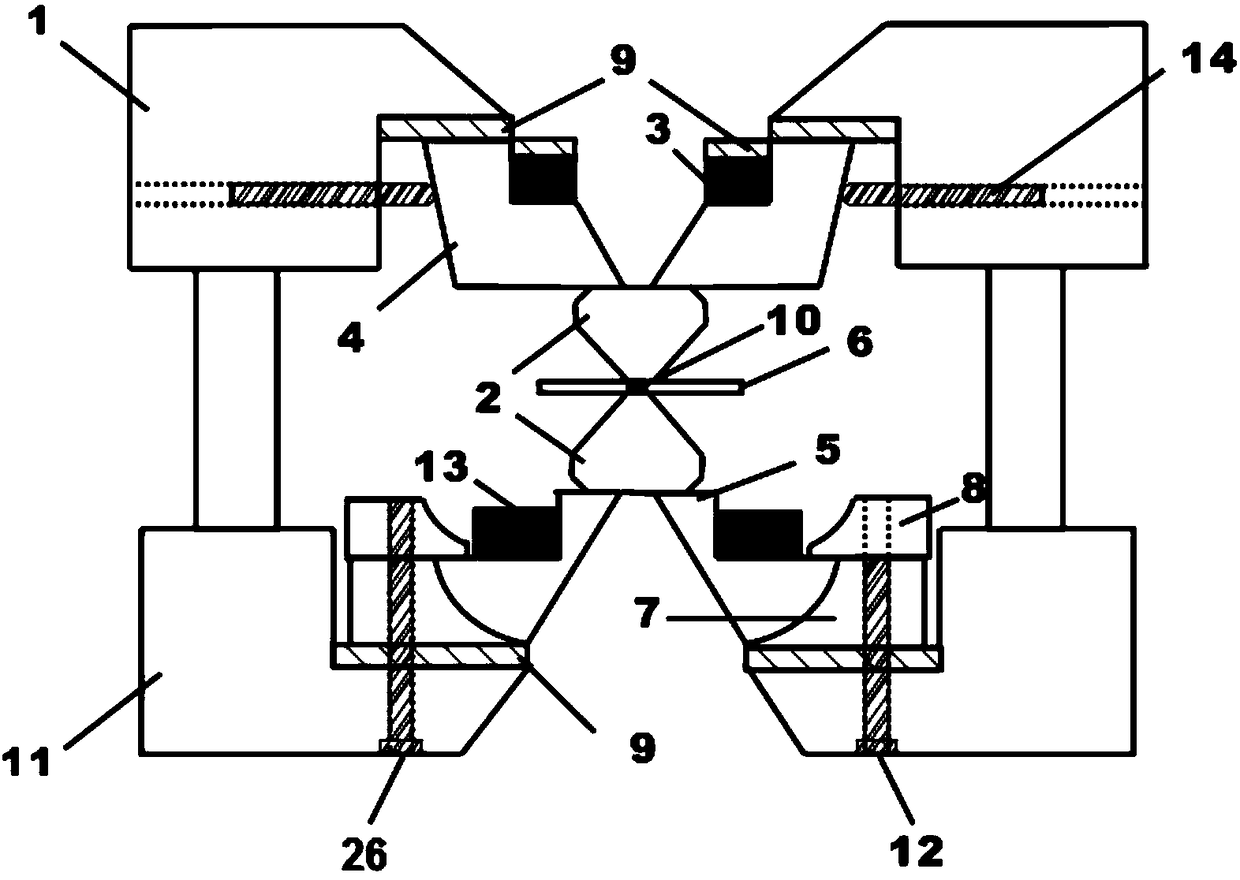

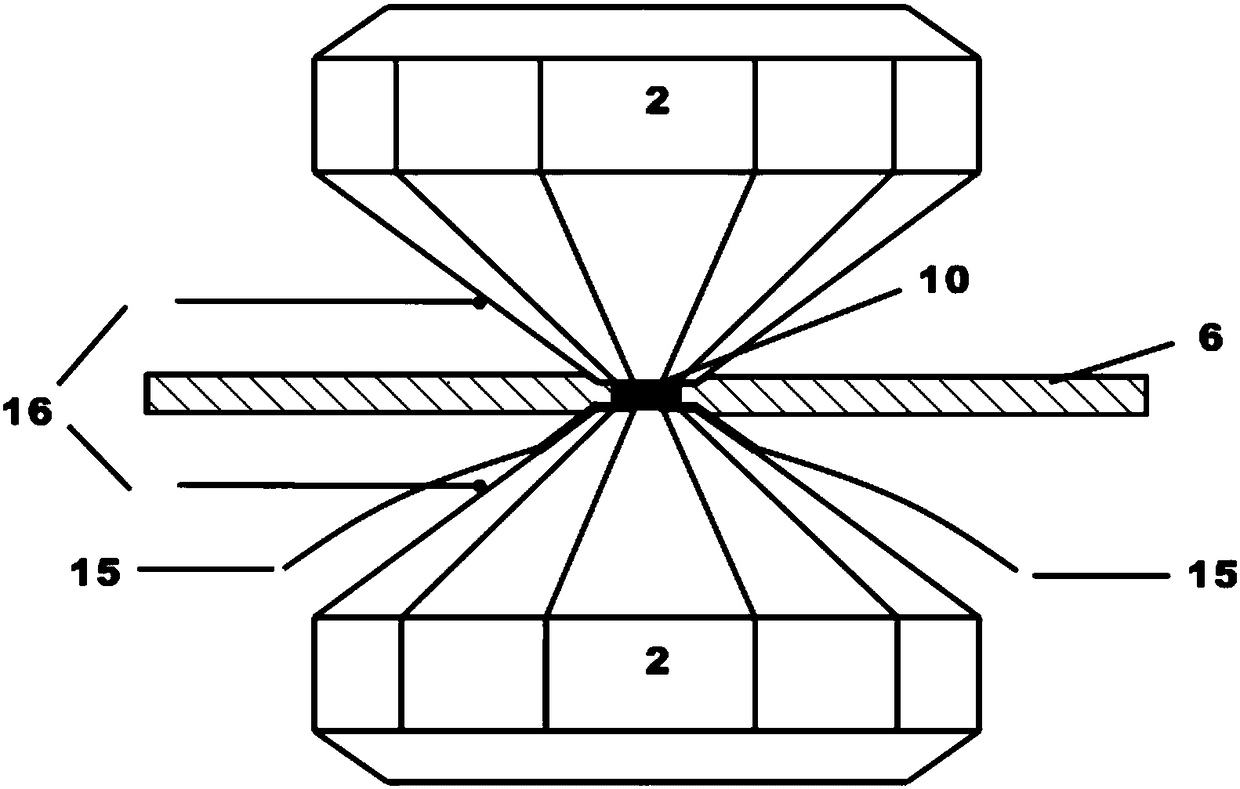

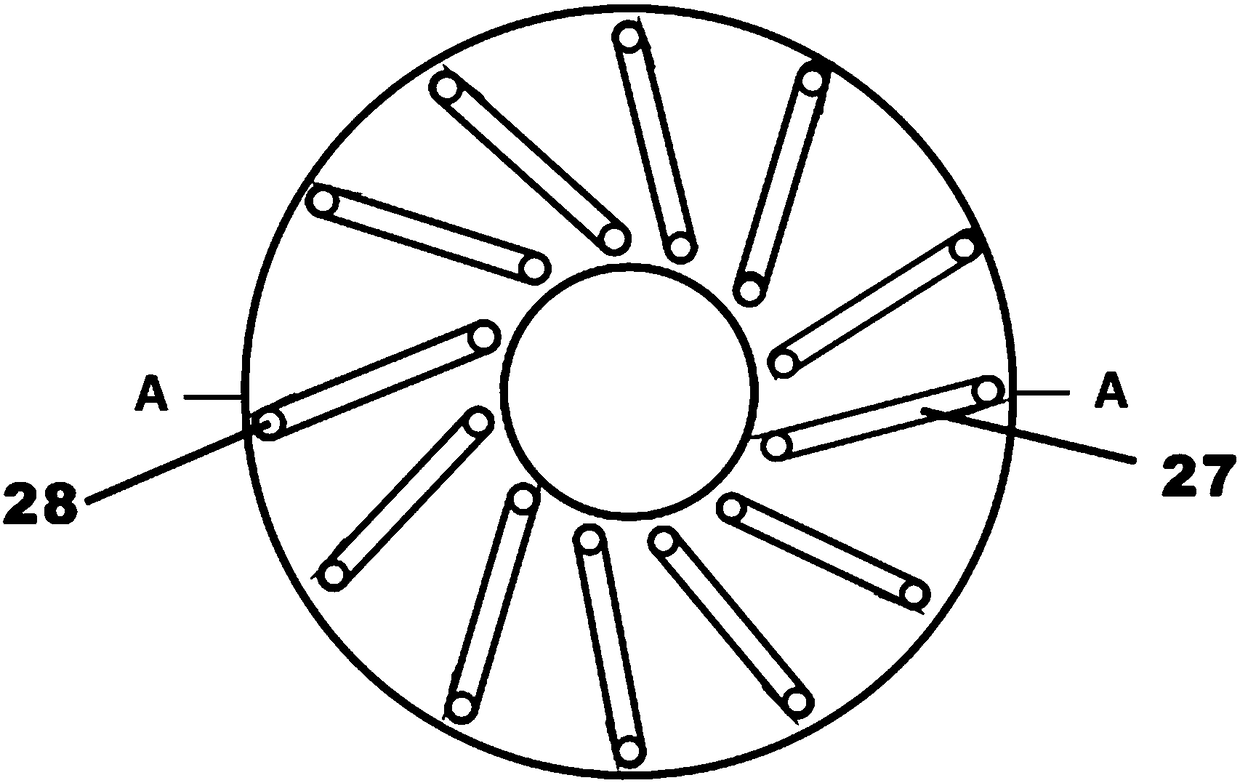

[0032] Embodiment 1 illustrates the structure of the present invention in conjunction with the accompanying drawings.

[0033] exist Figure 1~6 Among them, 1 is the upper mold of the press, 2 is the diamond anvil, 3 is the ceramic mold of the bracket end, 4 is the bracket, 5 is the shaker, 6 is the metal gasket, 7 is the shaker base, and 8 is the shaker cover , 9 is the mica sheet, 10 is the sample, 11 is the lower mold of the press, 12 is the fixing screw, 13 is the ceramic mold at the shaker end, 14 is the centering screw, 26 is the leveling screw, 15 is the test electrode, 16 is the thermoelectric Even, 27 is a groove, and 28 is a flat bottom mold hole, and 29 is a circular step, and 30 is a trapezoidal mold hole.

[0034] The upper die 1 of the press and the lower die 11 of the press are constructed into a press with a four-column structure. Two diamond anvils 2 are placed in the internal space of the upper die 1 of the press and the lower die 11 of the press, and a met...

Embodiment 2

[0039] Example 2 combined figure 1 , 2 The assembly process of the high temperature and high pressure diamond-anvil press is illustrated.

[0040] Step 1: Remove the stains on the surface of the diamond anvil 2 by conventional methods. Put the diamond anvil 2 into a mixture of acetone and alcohol and ultrasonically remove the stains on the surface for 20 minutes. After taking it out, rinse it with deionized water.

[0041] Step 2: Fix the cleaned two diamond anvils 2 on the support block 4 and the shaker 5 respectively by using a public press, and adjust the position of the diamond anvil 2 so that the center of the anvil surface of the diamond anvil 2 and the support The central holes of the block 4 and the shaking table 5 coincide, and the pressurizing screw of the public press is rotated to make the diamond anvil 2 closely bond with the supporting block 4 and the shaking table 5.

[0042] Step 3: Mix the high-temperature repair agent A and B evenly according to the mass ra...

Embodiment 3

[0048] Example 3 combined figure 1 , Figure 3-6 Explain the winding method of the heating wire and the installation of the ceramic mold.

[0049]Step 1: According to the experimental requirements, determine the ceramic mold 3 at the bracket end and the ceramic mold 13 at the shaker end to select a flat-bottomed mold or a trapezoidal mold.

[0050] Step 2: Select a flat-bottomed mold, and cross-wind the upper and lower surfaces of the heating wire. During the winding process, pay attention to ensure that the heating wire is embedded in the groove of the mold to prevent the exposed part of the heating wire from contacting with the support block or shaking table during the experiment. Trapezoidal mould, wrap the heating wire radially inside and outside sequentially. During the winding process, care should be taken to ensure that the heating wire can be covered by the edge of the ladder, and also prevent the exposed part of the heating wire from contacting with the support block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com