A kind of method for cleaning test tube with mouthpiece based on corrosive cleaning solution

A cleaning method and a cleaning solution technology, which are applied in cleaning methods and utensils, chemical instruments and methods, and cleaning hollow objects, etc., can solve the problems of neglecting test tube cleaning, tediousness, and use of stains, so as to improve cleaning efficiency, reduce labor intensity, The effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

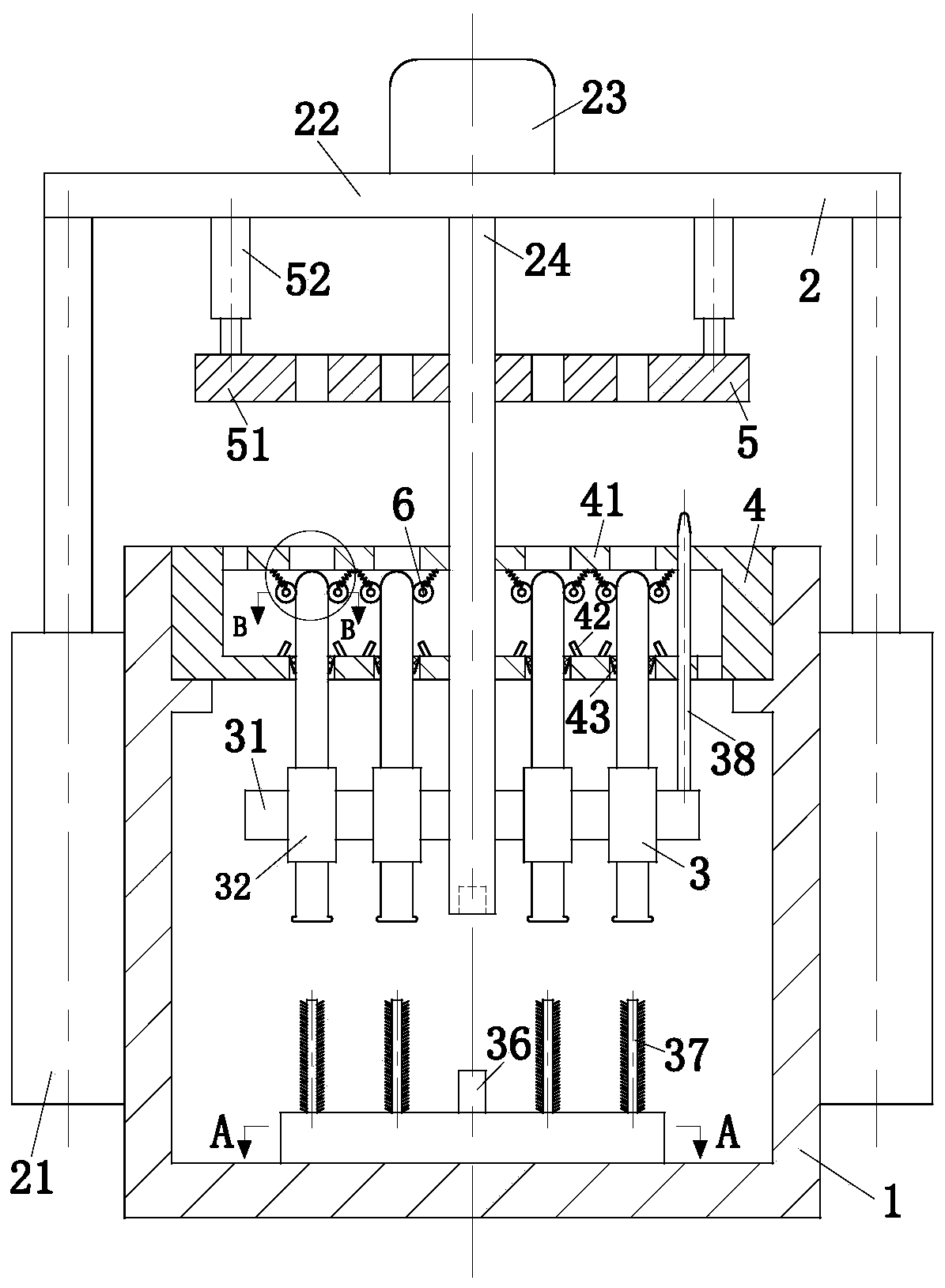

[0028] like Figure 1 to Figure 5 Shown, a kind of test tube cleaning method based on corrosive cleaning solution of the present invention, comprises the following steps:

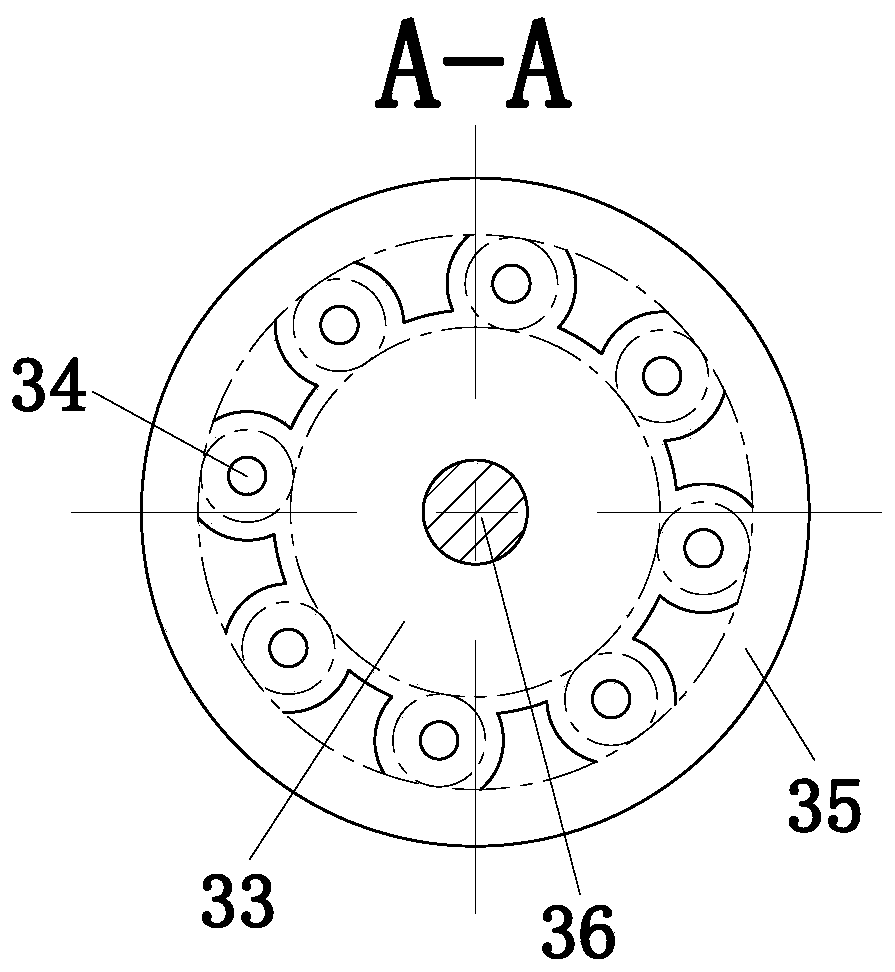

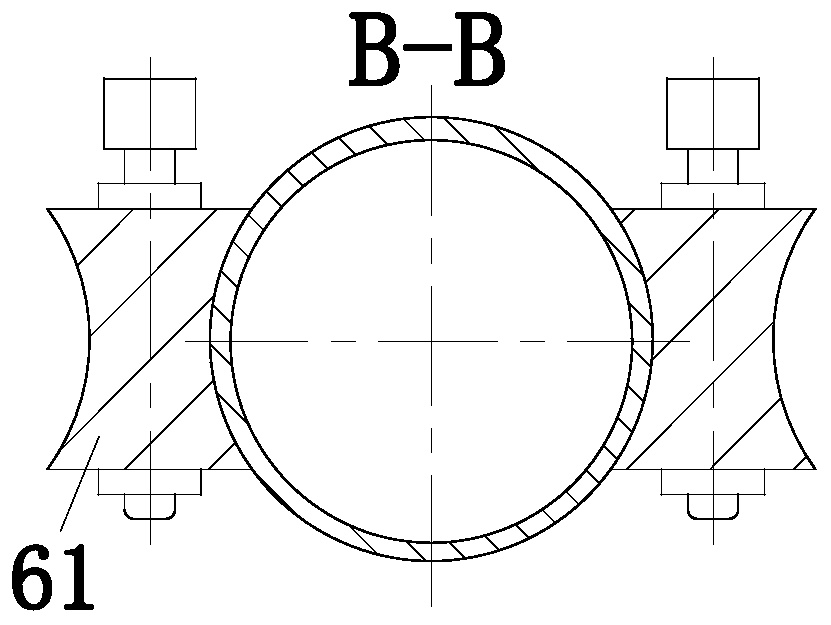

[0029] A: When it is necessary to clean the test tube, insert the test tube into the clamping hole of the loading plate 51 with the mouth facing down, the cylinder 2 52 drives the loading plate 51 to move downward, and the test tube enters the rinsing box 41, and the water in the rinsing box 41 The tube delivery wheel 61 promotes the test tube to pass through the rinsing box 41 downwards and move onto the cleaning tray 31, and the fixed clip 32 clamps the test tube; then, the cylinder one 21 moves downward, and the cleaning tray 31 moves downward together with the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com