Water-soluble vanishing model core as well as preparation method and application thereof

A water-soluble, model-based technology, applied in cores, casting molding equipment, casting molds, etc., to solve the problems of easily damaged green bodies, and the inability to use gel injection molding for soluble disappearing model cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a water-soluble disappearing model core. The preparation method comprises steps: S1, mixing gypsum, magnesium sulfate, water and ceramic powder in proportion, and stirring evenly to obtain a mixed slurry; S2, mixing the mixed slurry The body is poured into a mold containing embedded parts, taken out after curing, and dried to obtain a water-soluble disappearing mold core.

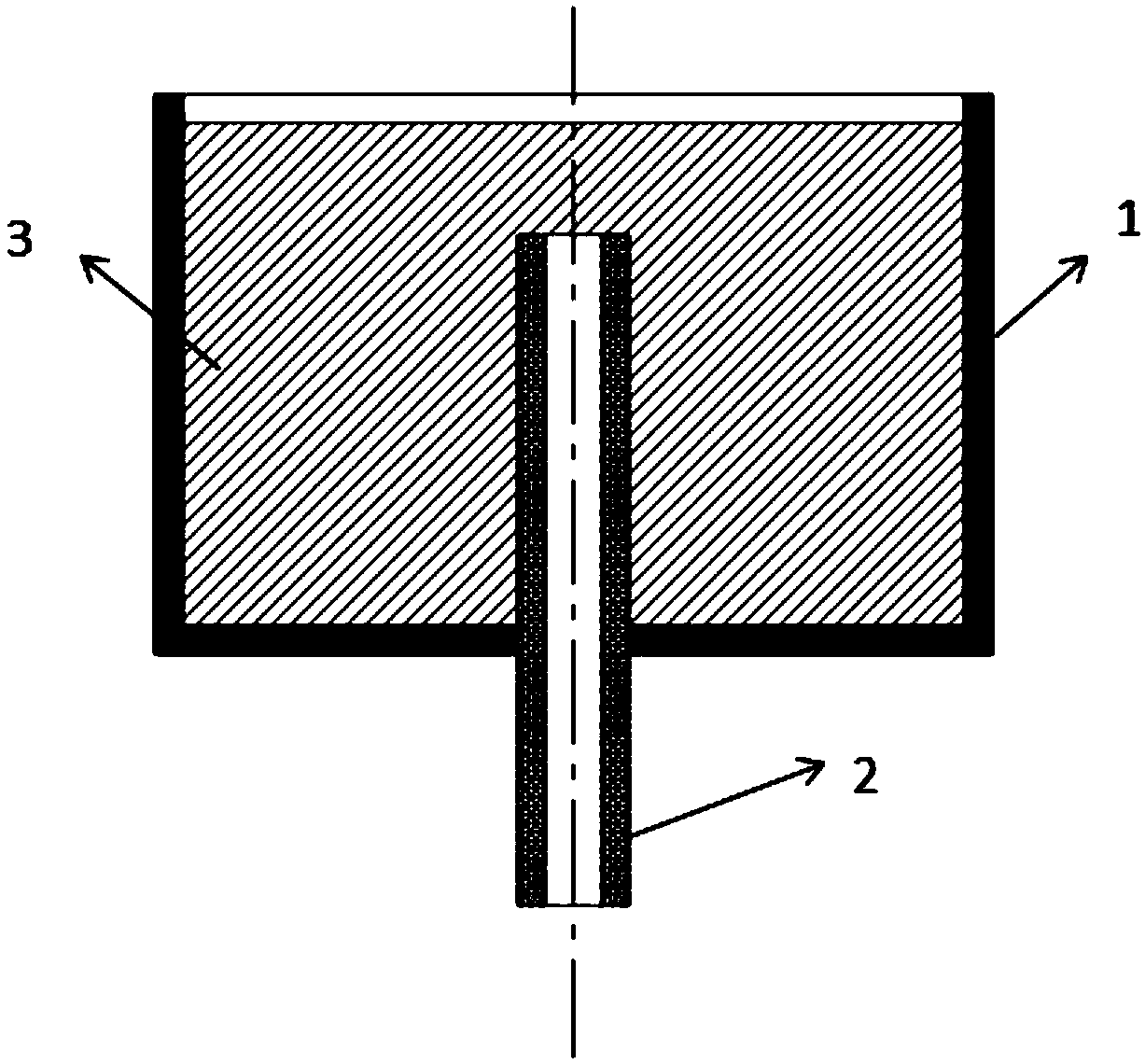

[0024] Specifically, the preparation method includes: designing and manufacturing the embedded part 3 in the water-soluble disappearing pattern core, designing and manufacturing a mold (not shown in the figure) for assembling the water-soluble disappearing pattern core, designing and manufacturing the pouring The mold 2 of the water-soluble disappearing model core, the embedded part 3 is arranged in the mold 2, the mold 2 is preferably a metal mold, the embedded part 3 is preferably a metal embedded part, and a part of the embedded part 3 is embedded in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com