Continuous friction-resistant ultraviolet-curing antifogging coating composition and preparation of coating layer of continuous friction-resistant ultraviolet-curing antifogging coating composition

An anti-fog coating, light-curing technology, used in coatings, epoxy coatings, polyurea/polyurethane coatings, etc., can solve the problems of general anti-fog performance, complex process, and long time required.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

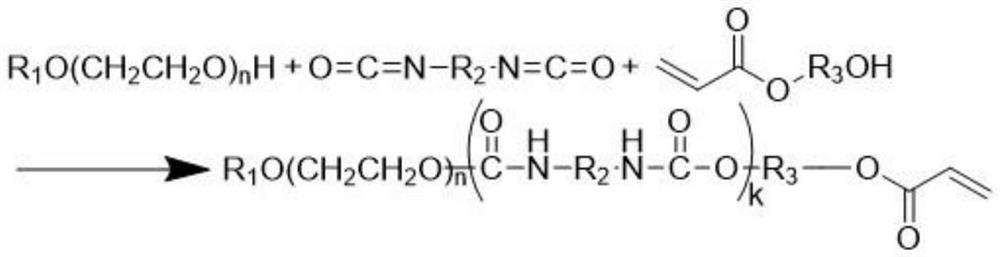

[0078] Preparation of Photocurable Acrylic Hydrophilic Resin A

[0079] Mix 0.1 mol of isophorone diisocyanate (IPDI) and 0.2 mol of hydroxyethyl acrylate (HEA), and the solvent is ethyl acetate. After reacting at 40°C for 2 hours, add 0.2 mol polyoxyethylene lauryl ether to continue the reaction for 3 hours.

Embodiment 2

[0081] Preparation of Photocurable Acrylic Hydrophilic Resin B

[0082] Mix 1.3 mol of dicyclohexylmethane diisocyanate (HMDI) and 2.4 mol of hydroxyethyl methacrylate (HEMA), and the solvent is ethyl acetate. After reacting at 50°C for 1 hour, 2.2 mol of cetyl alcohol polyoxyethylene ether was added to continue the reaction for 4 hours.

Embodiment 3

[0084] Preparation of Photocurable Acrylic Hydrophilic Resin C

[0085] Mix 1 mol of hexamethylene diisocyanate (HDI) and 2.4 mol of pentaerythritol triacrylate (PETA), and the solvent is ethyl acetate. After reacting at 60°C for 2 hours, 2.2 mol of stearyl polyoxyethylene ether was added to continue the reaction for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com