Enzyme granules for face-washing soap and its preparation method and application

A cleaning soap and enzyme technology, applied in the field of washing, can solve the problems of weakening the ability to remove oil and cleaning, and not having the ability to exfoliate, and achieve the effect of improving oil control cleaning ability, rapid drying and less skin irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

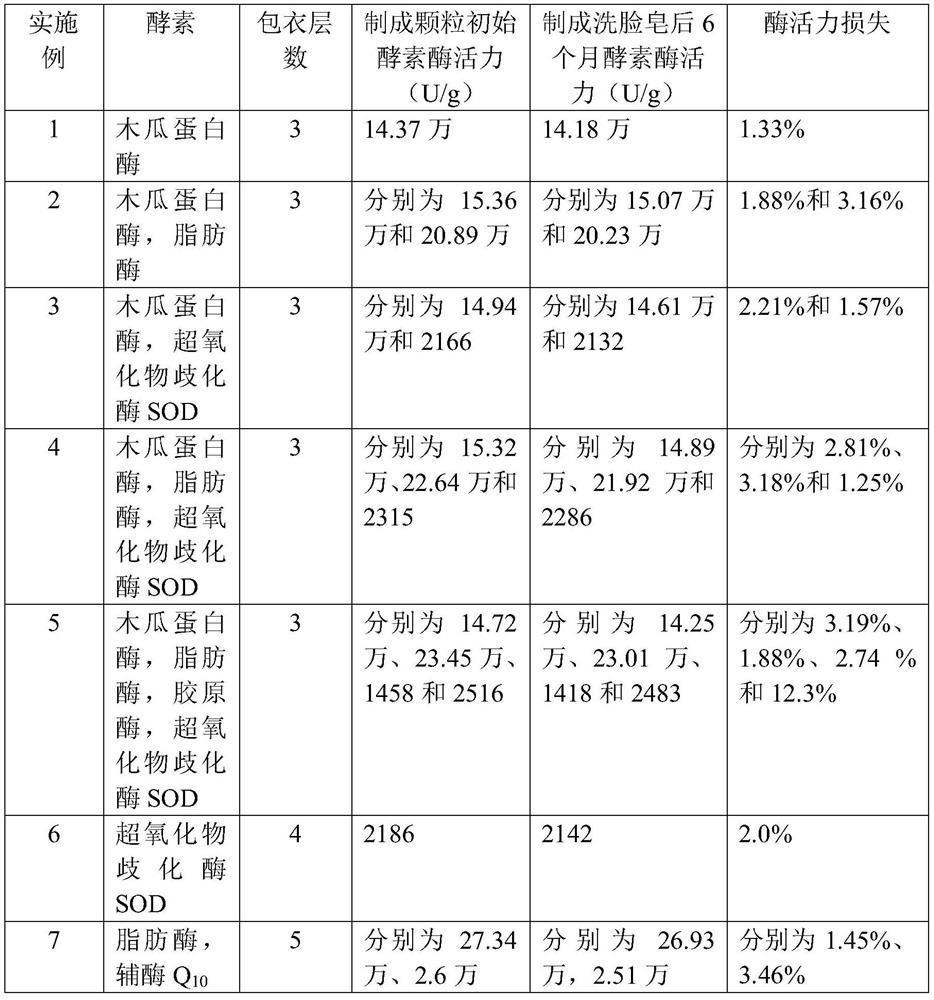

Embodiment 1

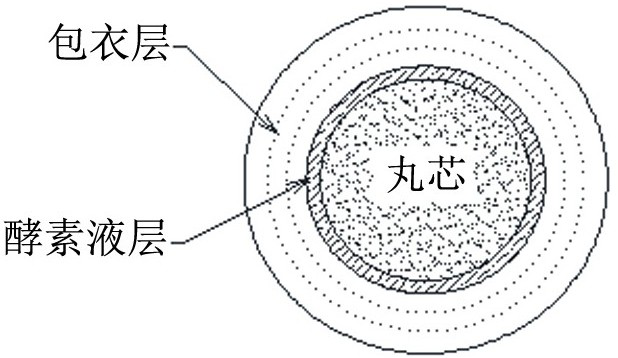

[0030] An enzyme granule for face wash and cleansing soap, which is composed of several layers of coatings from the inside and outside of the pellet core, the enzyme liquid sprayed on the pellet core, and the outer layer sprayed; the soap enzyme granules are prepared from the following weight percentages of raw materials : 5% pellet core, 5% enzyme solution, 90% coating layer;

[0031] The pellet core consists of 10% by weight grafted starch and 90% Glauber's salt.

[0032] The enzyme solution consists of 90% papain by weight and 10% peptide aldehyde.

[0033] The coating layer is composed of 10% / 8% / 7% indigo / brilliant green / comfrey, talc 36% / 38% / 37%, and polyvinylpyrrolidone (PVP) 54% / 54% / 56% by weight.

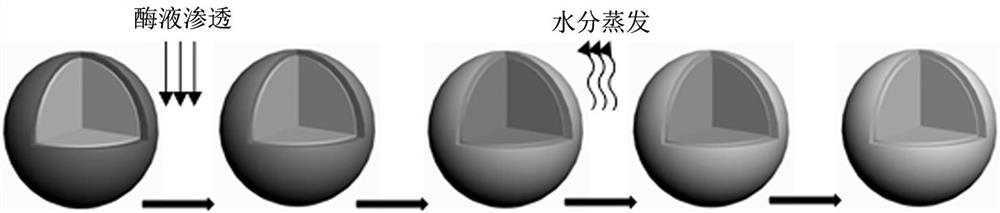

[0034] The steps of the method for preparing the above-mentioned enzyme granules for soap are: mixing and extruding the filler and binder used in the pellet core in an extruder, spheronizing in the spheronizing machine to form a blank pellet core, and the size of the pellet core is ...

Embodiment 2

[0037] An enzyme granule for face wash and cleansing soap, which is composed of several layers of coatings from the inside and outside of the pellet core, the enzyme liquid sprayed on the pellet core, and the outer layer sprayed; the soap enzyme granules are prepared from the following weight percentages of raw materials : 10% pellet core, 25% enzyme solution, 65% coating layer;

[0038] The pellet core is composed of 80% calcium carbonate and 20% oxidized starch by weight.

[0039] The enzyme solution is composed of 60% papain, 38% lipase, and 2% amide by weight.

[0040] The coating layer is made up of 7% by weight indigo / brilliant green / comfrey, 60% / 69% / 78% cellulose / methylcellulose / ethyl cellulose, 33% / 24 % / 15% polyvinyl alcohol (PVA).

[0041] The steps of preparing the above-mentioned enzyme granules for soap are as follows: mixing and extruding the filler and binder used in the pellet core in an extruder, spheronizing in the spheronizing machine to form a blank pellet core, th...

Embodiment 3

[0044] An enzyme granule for face wash and cleansing soap, which is composed of several layers of coatings from the inside and outside of the pellet core, the enzyme liquid sprayed on the pellet core, and the outer layer sprayed; the soap enzyme granules are prepared from the following weight percentages of raw materials : 20% pellet core, 30% enzyme solution, 50% coating layer;

[0045] The pellet core is composed of 80% sodium sulfate by weight and 20% starch.

[0046] The enzyme solution is composed of 81% papain by weight, 18% superoxide dismutase SOD, and 1% polyamide.

[0047] The coating layer is made of 5% / 7% / 8% indigo / brilliant green / comfrey, 40% / 36% / 32% polyvinyl chloride (PVC), 55% / 57% / 60% kaolin .

[0048] The steps of preparing the above-mentioned enzyme granules for soap are: mixing and extruding the filler and binder used in the pellet core in an extruder, spheronizing in the spheronizing machine to form a blank pellet core, and the size of the pellet core is controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap