Assembly type plastic pressure pipe, production die, production method as well as plastic plate and pipe gallery

A production method and technology for pressure pipes, which are applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of expensive equipment, low yield and difficult operation of large-diameter plastic pressure pipes, and achieve high ring stiffness, The effect of high yield and low production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

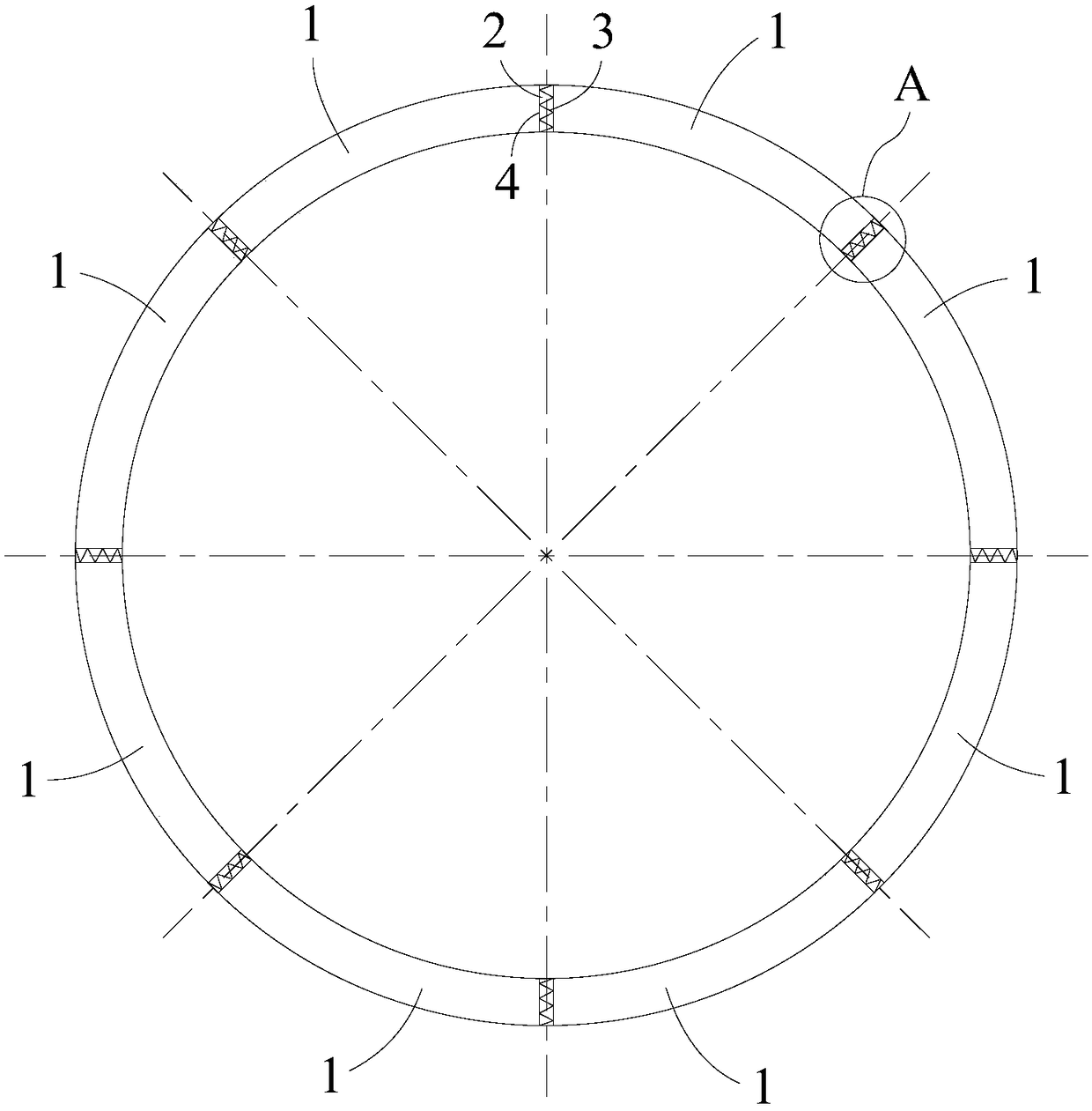

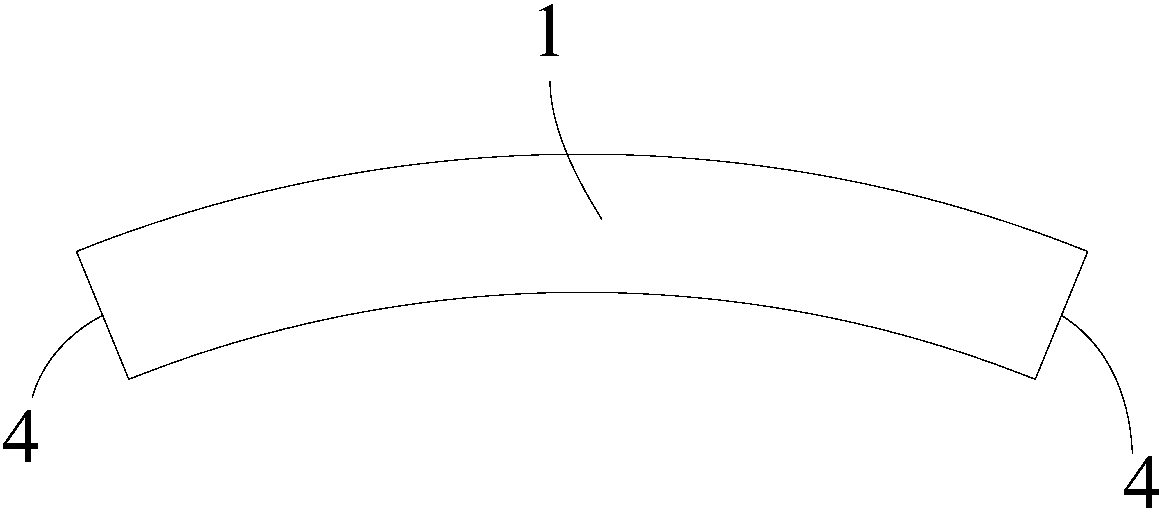

[0070] Such as Figure 1-7 As shown, an assembled plastic pressure pipe according to the present invention includes eight segments 1 .

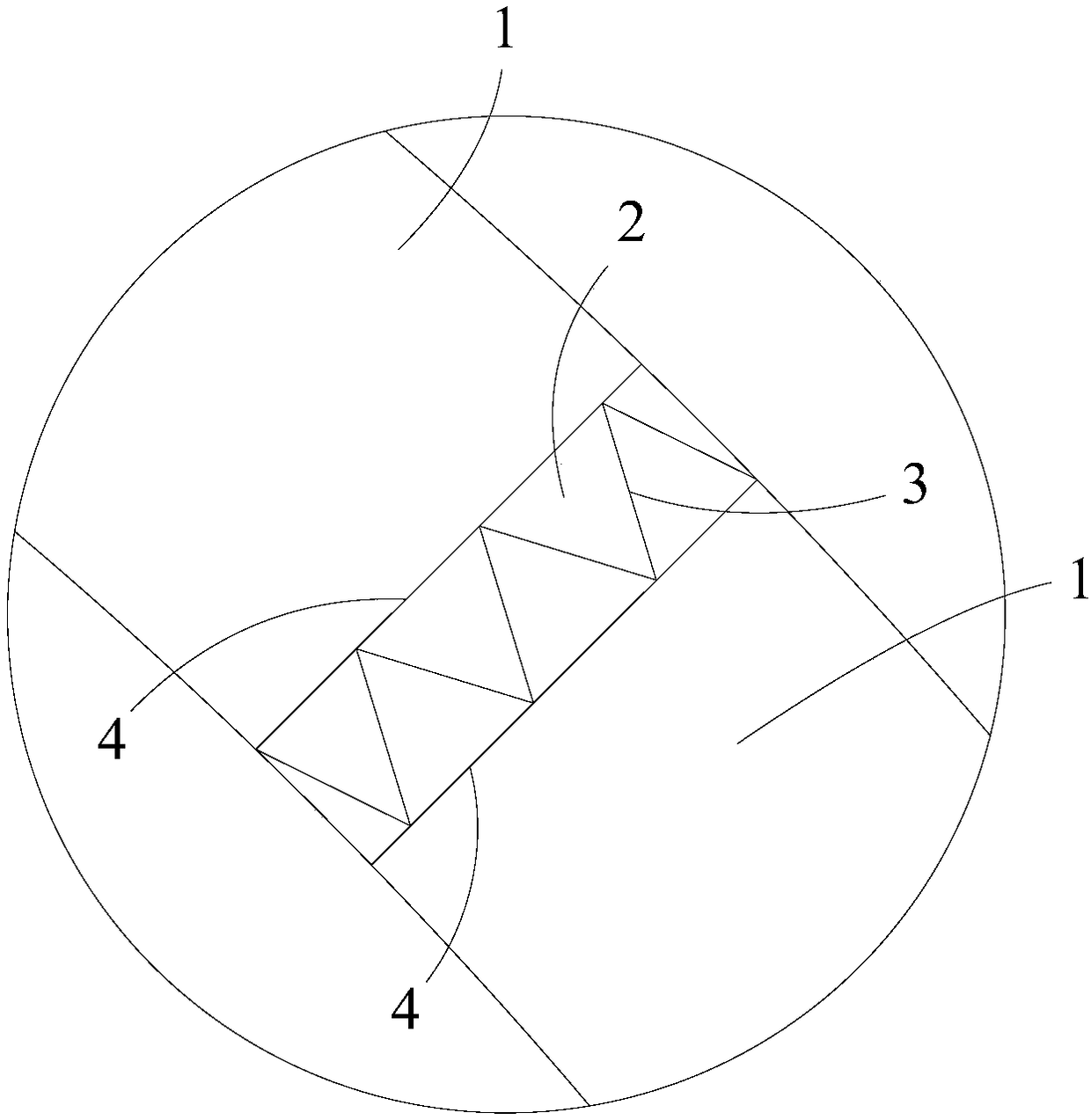

[0071] All the tube pieces 1 can be spliced in sequence to form a plastic pressure pipe body, two adjacent tube pieces 1 are hot-melt welded, and a heating wire 3 is arranged in the joint.

[0072] As a preferred solution of this embodiment, each of the segments 1 has the same shape and size, and this structural arrangement facilitates the production and storage management of the segments 1; Protrusions 11 are provided on the longitudinal end wall 4, and the heating wire 3 is arranged in two adjacent protrusions 11. With this structure, the area of the joint between two adjacent tube pieces 1 is increased, so that The formed whole pipe has good connection effect and high structural strength. At the same time, the protrusions 11 form longitudinal stiffening ribs, which further strengthen the ring rigidity of the whole pipe, making the who...

Embodiment 2

[0075] Such as Figure 1-7 As shown, a kind of production mold of the assembled plastic pressure pipe as described in embodiment 1 of the present invention comprises:

[0076] Extrusion molding die, used for extruding and molding each segment 1;

[0077] A mandrel, the shape of which is adapted to the diameter of the plastic pressure pipe to be produced, and the mandrel is used to sequentially set all the segments 1 to initially form the shape of the plastic pressure pipe;

[0078] Compression dies, the number of which is adapted to the number of segments 1, and corresponding to each segment 1, the compression dies are adapted to the mandrel, and the compression dies are used for the respective corresponding Pushing and applying pressure of segment 1;

[0079] a driving part, used to drive the movement of the stamper, so that the stamper approaches or moves away from the mandrel;

[0080] A power supply, used to communicate with each of the heating wires 3;

[0081] The co...

Embodiment 3

[0084] Such as Figure 1-7 As shown, a kind of production method of the assembly type plastic pressure pipe production mold described in embodiment 2 of the present invention, comprises the following steps:

[0085] a. The extrusion molding die sequentially extrudes each of the segments 1 required for molding;

[0086] b. Surround all the segments 1 in turn around the periphery of the mandrel, and install heating wires 3 between the end walls 4 of two adjacent segments 1 to initially form the shape of a plastic pressure tube;

[0087] c. All the heating wires 3 are connected to the power supply, and the power supply makes all the heating wires 3 heat, and the corresponding end wall 4 of each heating wire 3 is thermally fused;

[0088] d. The driving part drives each of the dies close to the mandrel, and each of the dies applies pressure to each of the segments 1 at the same time, so that two adjacent thermally fused end walls 4 Combined under pressure;

[0089] e. The power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com