Valve tightness detecting device

A sealing detection and valve technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the problem of affecting detection efficiency, increasing detection workload, and easily causing false detection, etc. problem, to achieve the effect of improving detection efficiency, facilitating automatic paving, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

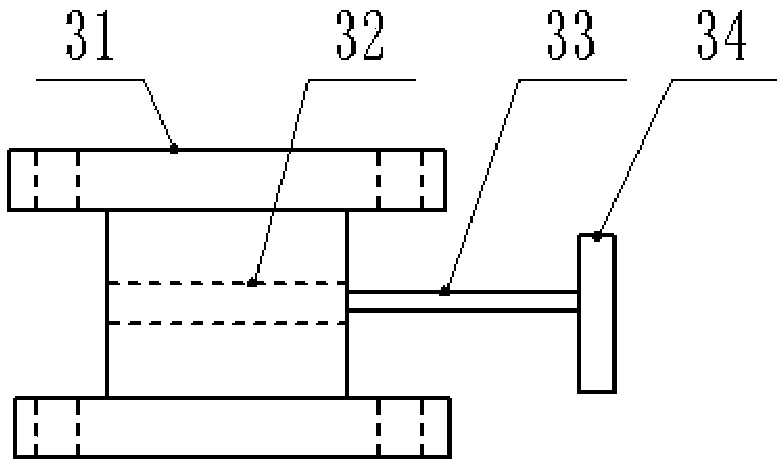

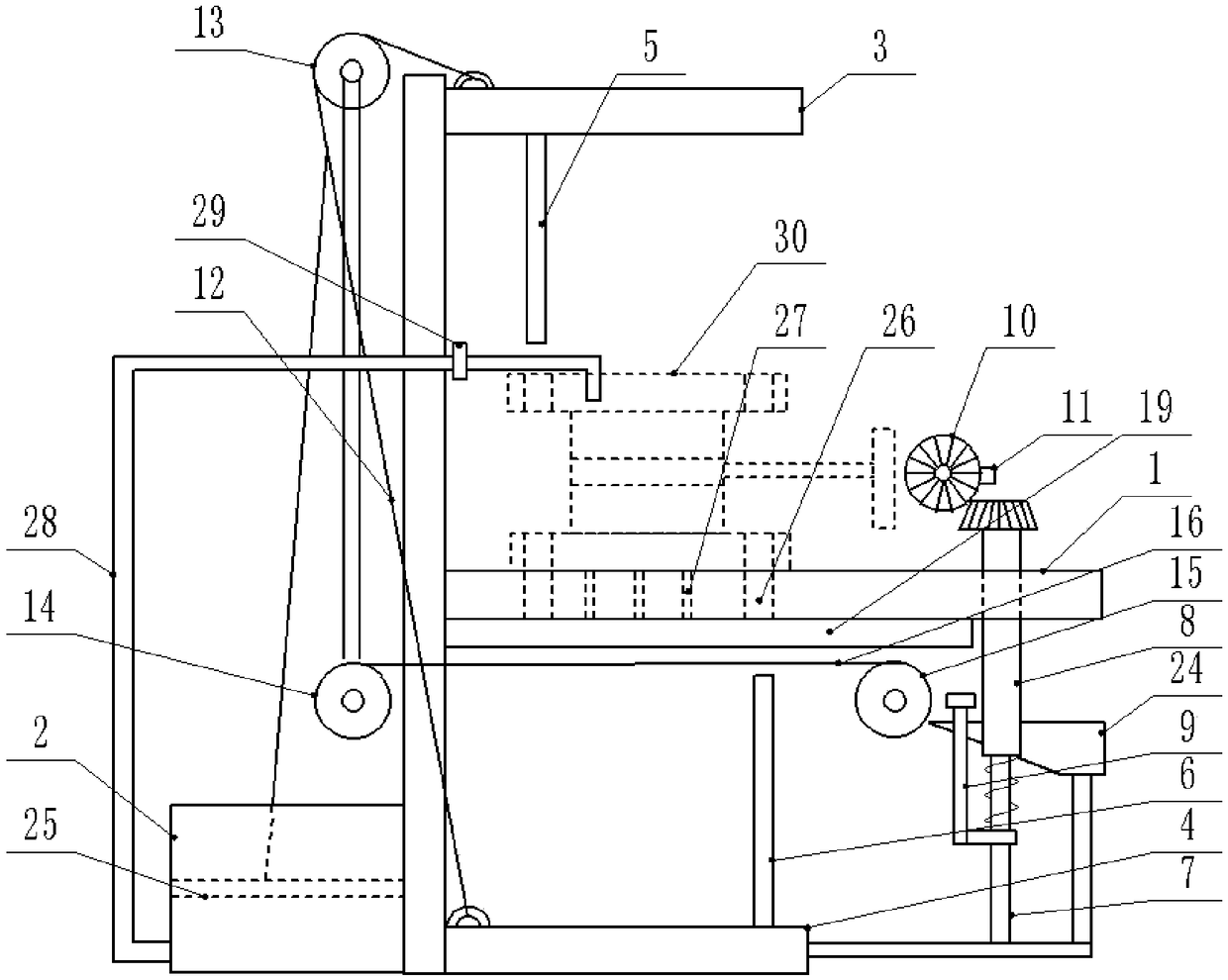

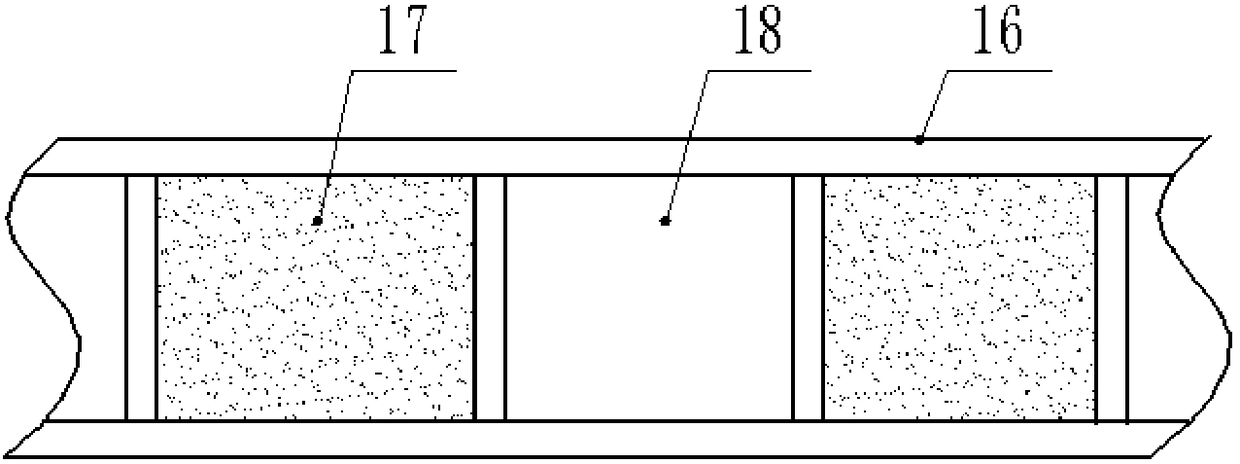

[0023] The reference signs in the drawings of the description include: detection table 1, iodine solution tank 2, first pressing plate 3, second pressing plate 4, first inserting rod 5, second inserting rod 6, lead screw 7, lead screw pair 8, Magnetic rod 9, auxiliary bevel gear 10, push tooth 11, pull cord 12, fixed pulley 13, first runner 14, second runner 15, tape 16, glutinous rice paper 17, gap 18, drain plate 19, through Hole 20, drain tank 21, drain hole 22, plugging ball 23, conical bucket 24, filter plate 25, socket 26, leak hole 27, liquid pipe 28, switch 29, valve 30, valve body 31, valve Core 32, valve stem 33, hand wheel 34.

[0024] Example figure 2 Shown: a valve sealing detection device, including a detection platform 1, a frame is provided on the left side of the detection platform 1, and a horizontal first pressure plate 3 and a second pressure plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com