Spherical fuel element automatic appearance detection device

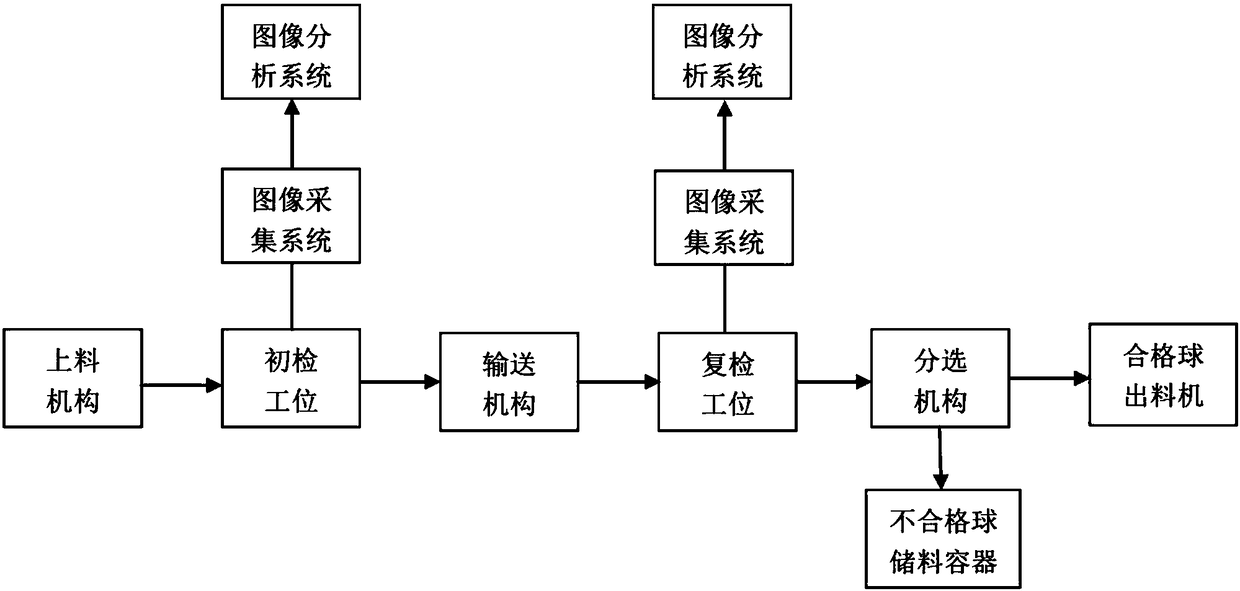

A spherical fuel element and appearance inspection technology, which is applied in the direction of measuring devices, analytical materials, and optical testing for flaws/defects, can solve the problems of low automation, increased labor costs and management costs of the company, and high false detection and missed detection rates. Achieve the effect of increasing the degree of automation, reducing labor costs and management costs, and saving quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

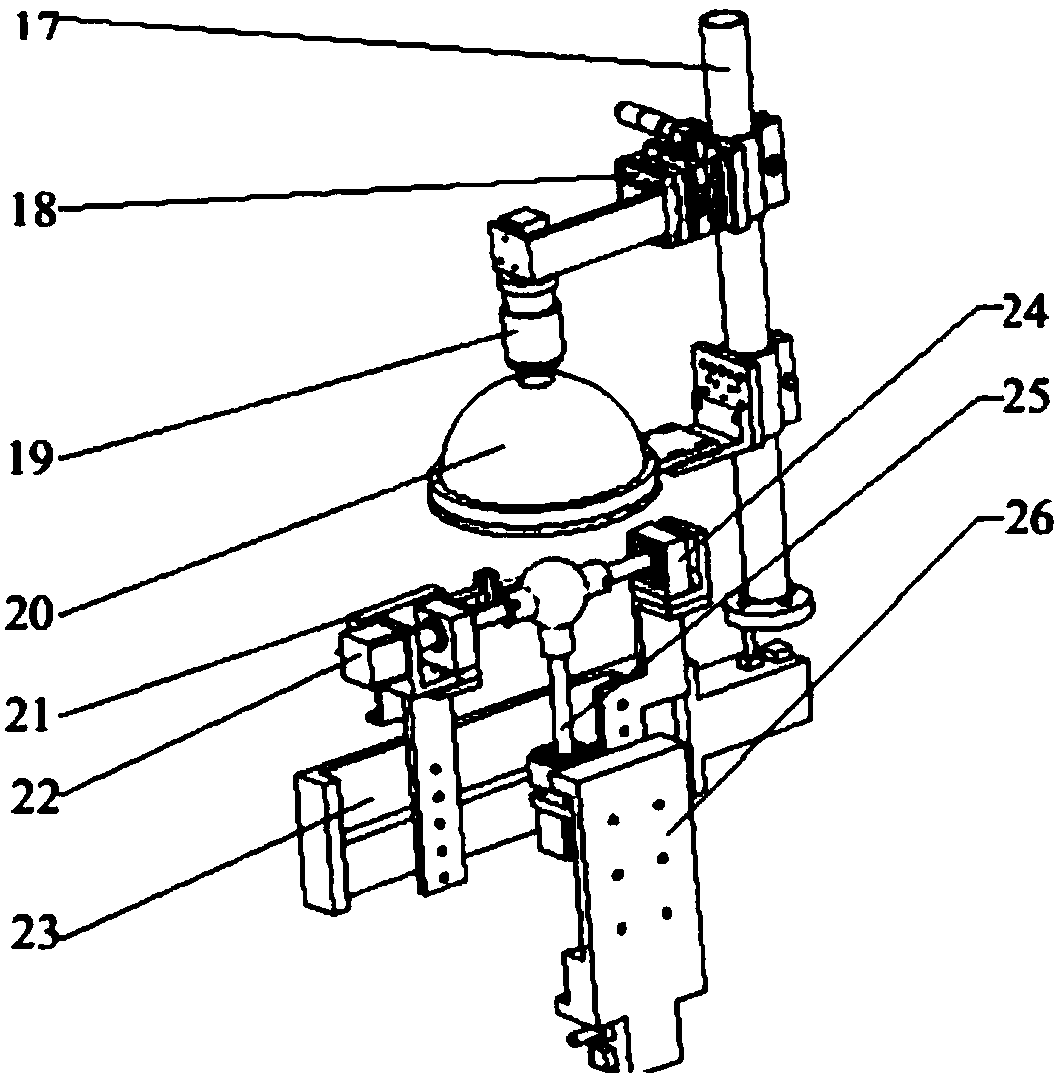

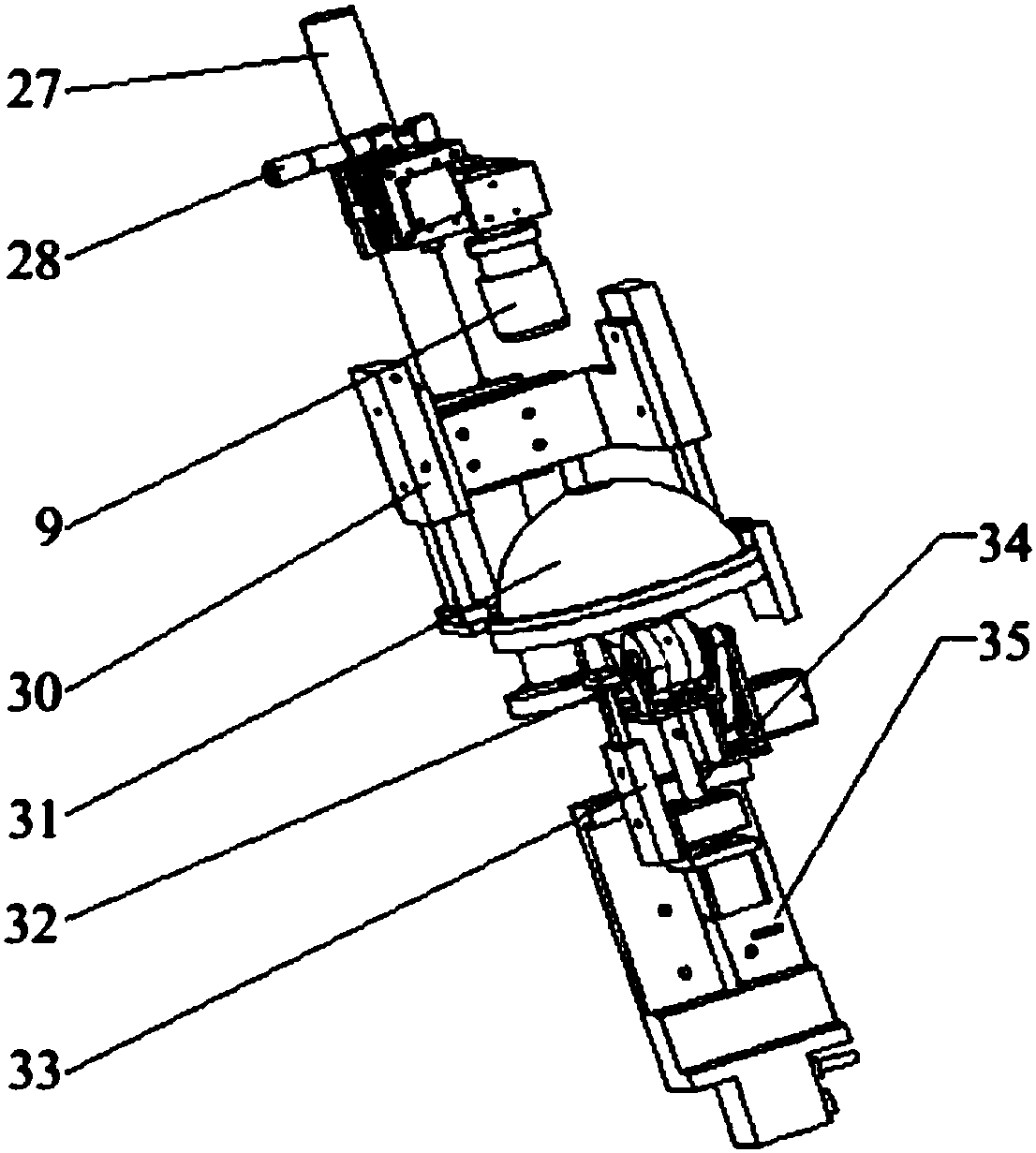

Method used

Image

Examples

Embodiment

[0029] After the development of the automatic appearance inspection device was completed, a comparison test between automatic appearance inspection and visual inspection was carried out. The surface quality inspection project of spherical fuel elements needs to inspect the surface finish, machining marks and chips, oil and other pollutants, pits, trachoma, gaps and machining marks and other defects of the element ball. The judgment standard is that one defect with a tangential length ≥ 5mm and a radial depth ≥ 2mm, or two defects with a tangential length ≥ 2mm and a radial depth ≥ 1mm are considered unqualified component balls.

[0030] Table 1 Comparison of test results between visual inspection and automatic appearance inspection device

[0031]

[0032] Through the comparison, it can be seen that the automatic appearance inspection device can effectively detect the surface defects of the component ball, which is no different from the visual inspection by personnel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com