Recycling and monitoring system for motor vehicle solid hazardous waste

A monitoring system and motor vehicle technology, applied in general control systems, control/regulation systems, transmission systems, etc., can solve the problems of backward disposal facilities, secondary pollution, large emissions, etc., to prevent leakage, The effect of effective treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

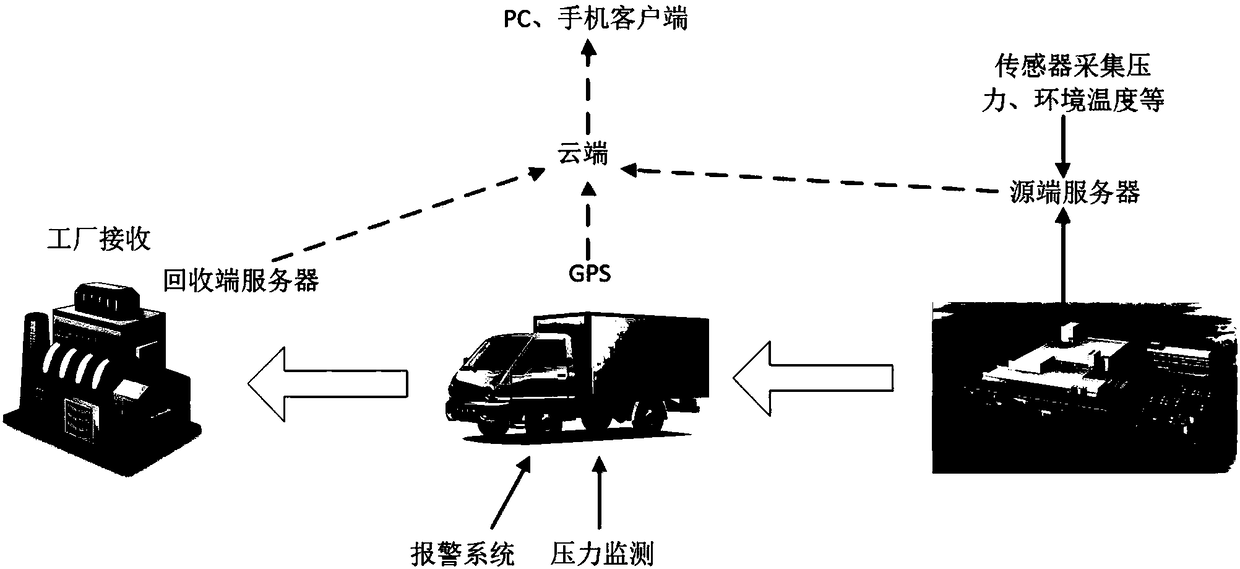

[0028] figure 1 It is a frame diagram of the present invention, such as figure 1 As shown, the present invention is a motor vehicle solid hazardous waste recycling monitoring system, including a source server, a recycling server, a cloud, and a client.

[0029] The source server is installed at the generation point of motor vehicle hazardous solid waste, such as various motor vehicle 4S stores, motor vehicle scrapping processing points, etc., and the recycling server is installed at the motor vehicle solid hazardous waste processing point, such as a special processing plant.

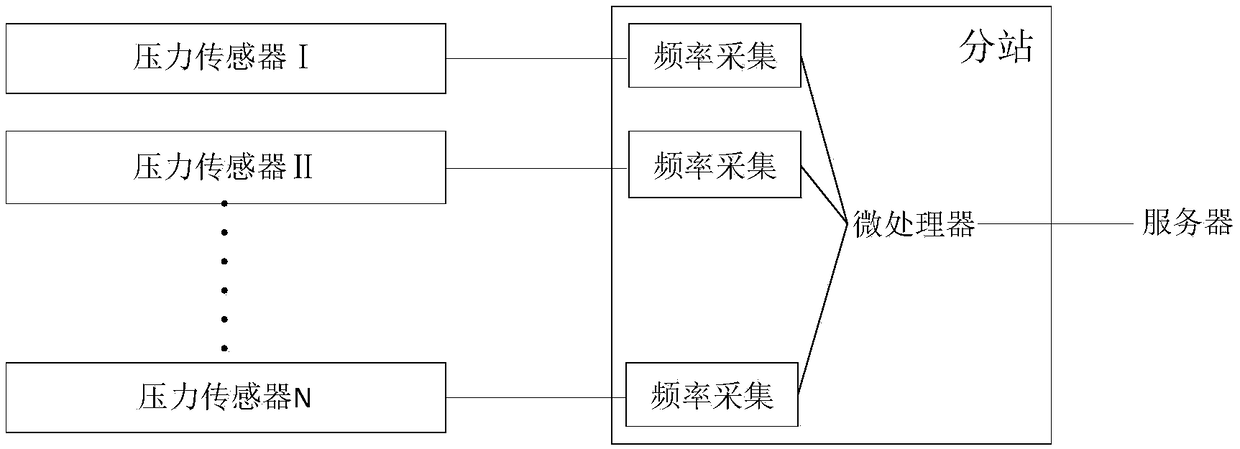

[0030] figure 2 It is a structural diagram of the source server of the present invention, the source server of the present invention is connected to a substation, the substation includes a microprocessor and multiple groups of frequency acquisition units, the frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com