Distributed drive-by-wire pressure feedback compensation air flotation vibration control system

A technology of feedback compensation and vibration control, which is applied in the direction of control/regulation system, mechanical vibration control, non-electric variable control, etc., can solve the problems of cumbersomeness, difficult maintenance and maintenance, and low compatibility of components, so as to avoid large The effect of displacement, good scalability, and good expansion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

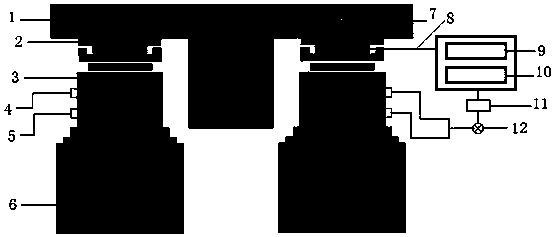

[0020] A distributed wire control pressure feedback compensation type air bearing vibration control system, see figure 1 , including at least two supporting rigid embedded plates 2 evenly distributed on the bottom surface of the rigid platform 1, pressure sensors 7 are respectively arranged under the supporting rigid embedded plates 2, and air flotation vibration damping is respectively arranged under the pressure sensors 7 Unit 3, the air flotation damping unit 3 is respectively provided with an air inlet 4 and an air outlet 5, the air inlet 4 is located above the air outlet 5, and the air flotation damping unit 3 is respectively provided with a concrete foundation pier 6; The sensors 7 are respectively connected to the data acquisition module 9 through the data wires 8 , and the data acquisition module 9 is respectively connected to the wire control device 11 and the pneumatic solenoid valve 12 on the air bearing damping unit 3 through the power supply module 10 respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com