Pressure container parameter design method for checking performance of underwater blasting equipment

A pressure vessel and parameter design technology, applied in the direction of material explosion, design optimization/simulation, computer-aided design, etc., can solve the problems of expensive cost and test cost, large-scale promotion and use, difficult large-scale dam, damage, etc., to overcome the rejection Explosive problem, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

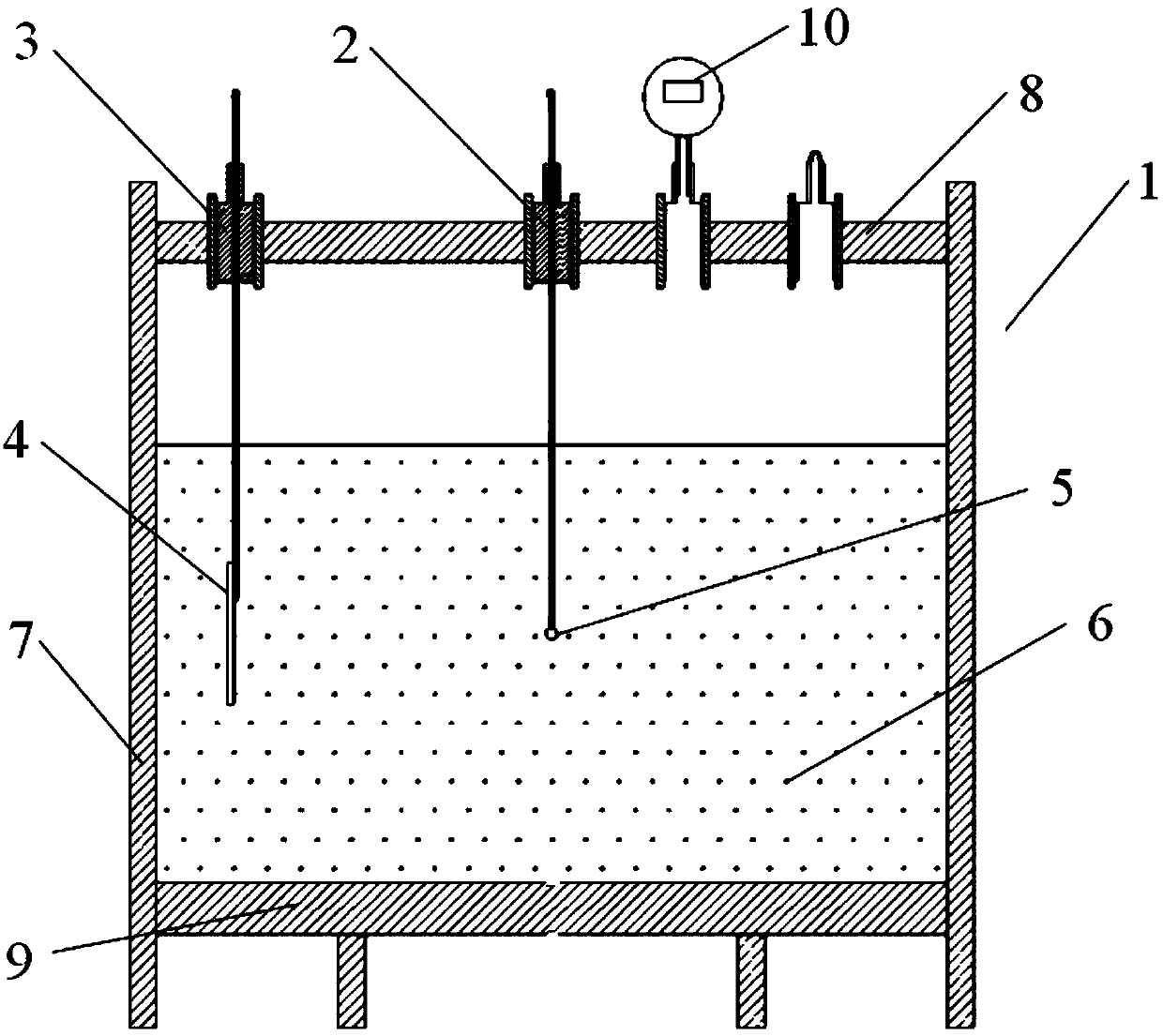

[0049] 1. Explosive devices and related measuring equipment

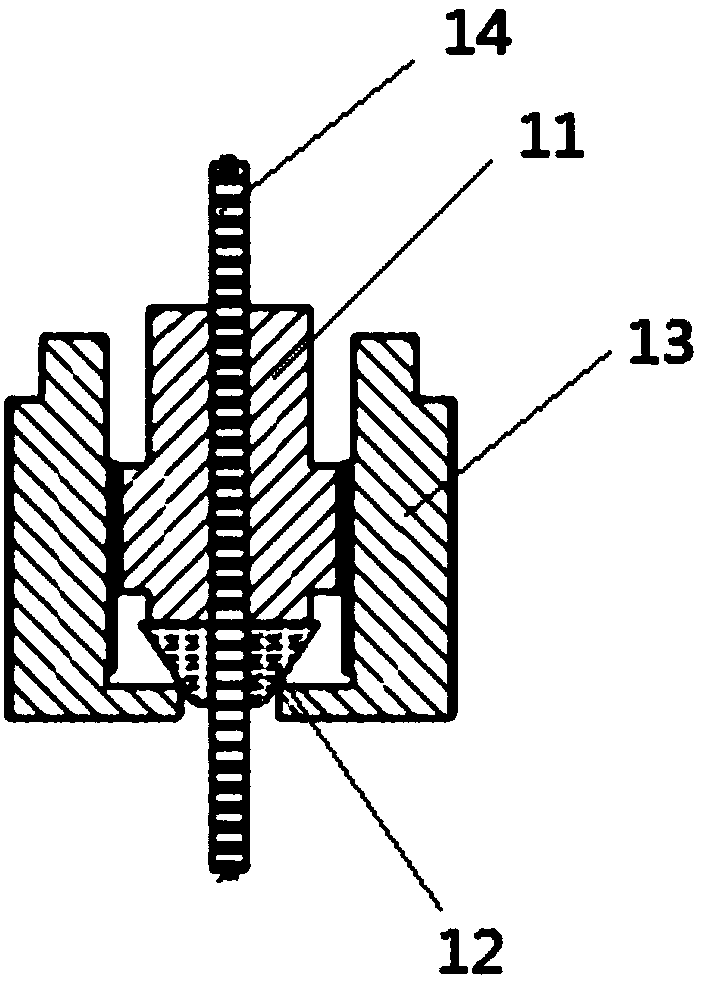

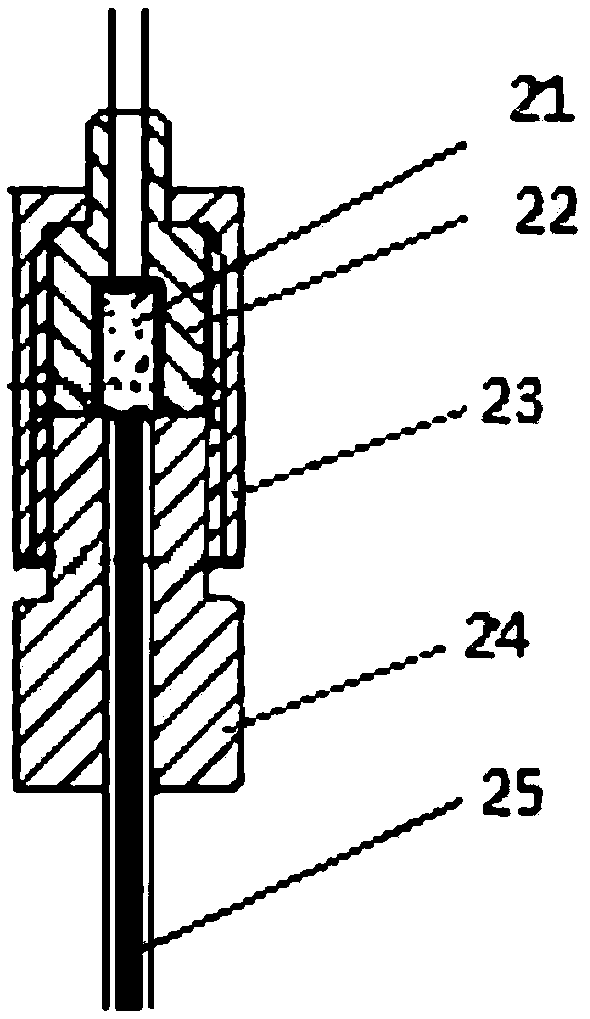

[0050] Such as figure 1 As shown, the underwater pressure explosion test device of the present invention comprises an explosion sealed container 1, an explosion assembly and a sensor 4, and the container 1 includes an upper cover plate 8, a base 9 and an outer wall 7, and the upper cover plate 8 is provided with a central through hole, a sensor through Hole and air pressure valve, explosion assembly and sensor 4 pass through the center through hole and sensor through hole respectively and are arranged in the container cavity; Sensor and charge are arranged at the same level, and explosion assembly and sensor 4 are sealed and fixedly connected by sealing joint 2 On the upper cover plate 8 of the container 1; the lower half of the container is filled with water, and the upper half is filled with high-pressure gas.

[0051] The charge and the sensor are arranged into the interior of the container from the two through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com