Potato picking and grading combined harvester

A combine harvester and potato technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of high labor intensity, shortened harvest period, and low production efficiency, so as to reduce labor intensity, reduce harvest costs, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

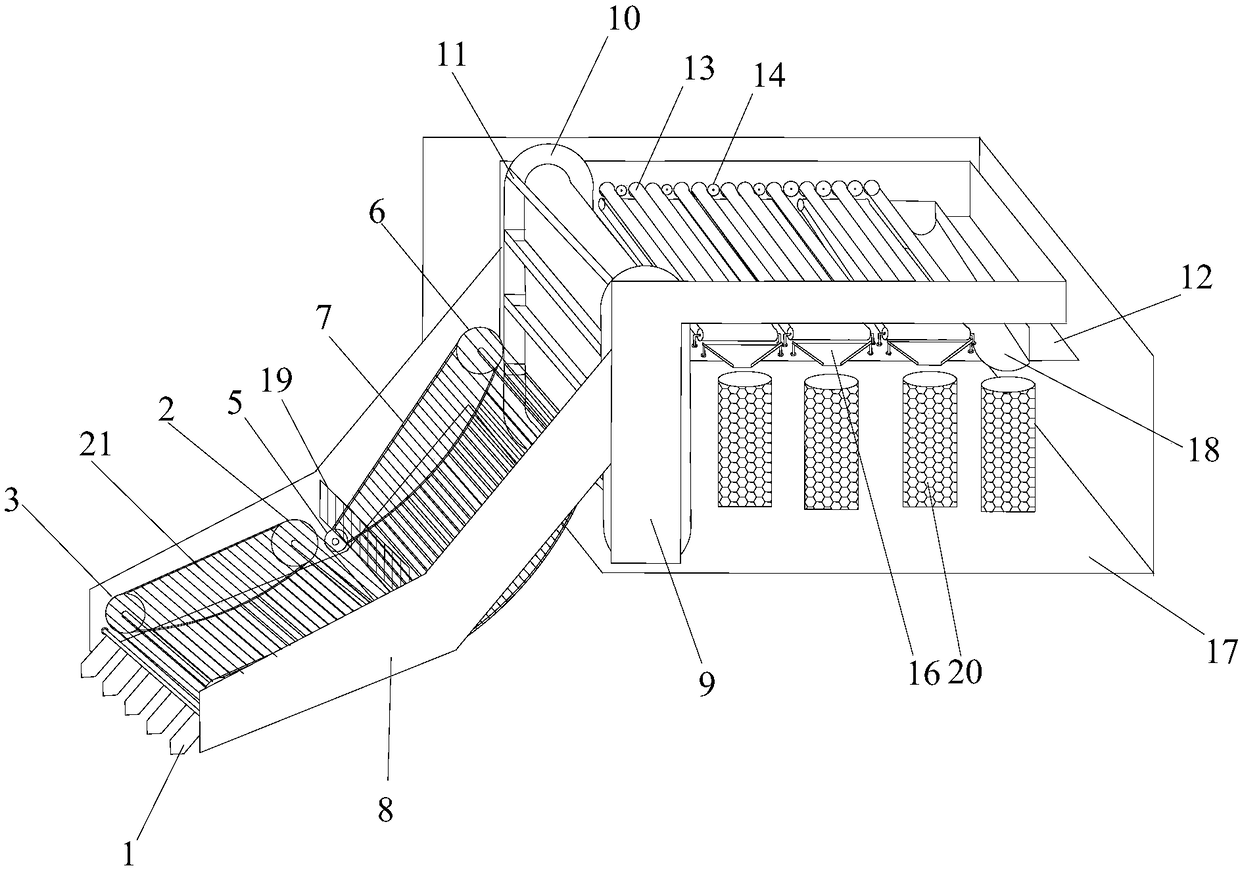

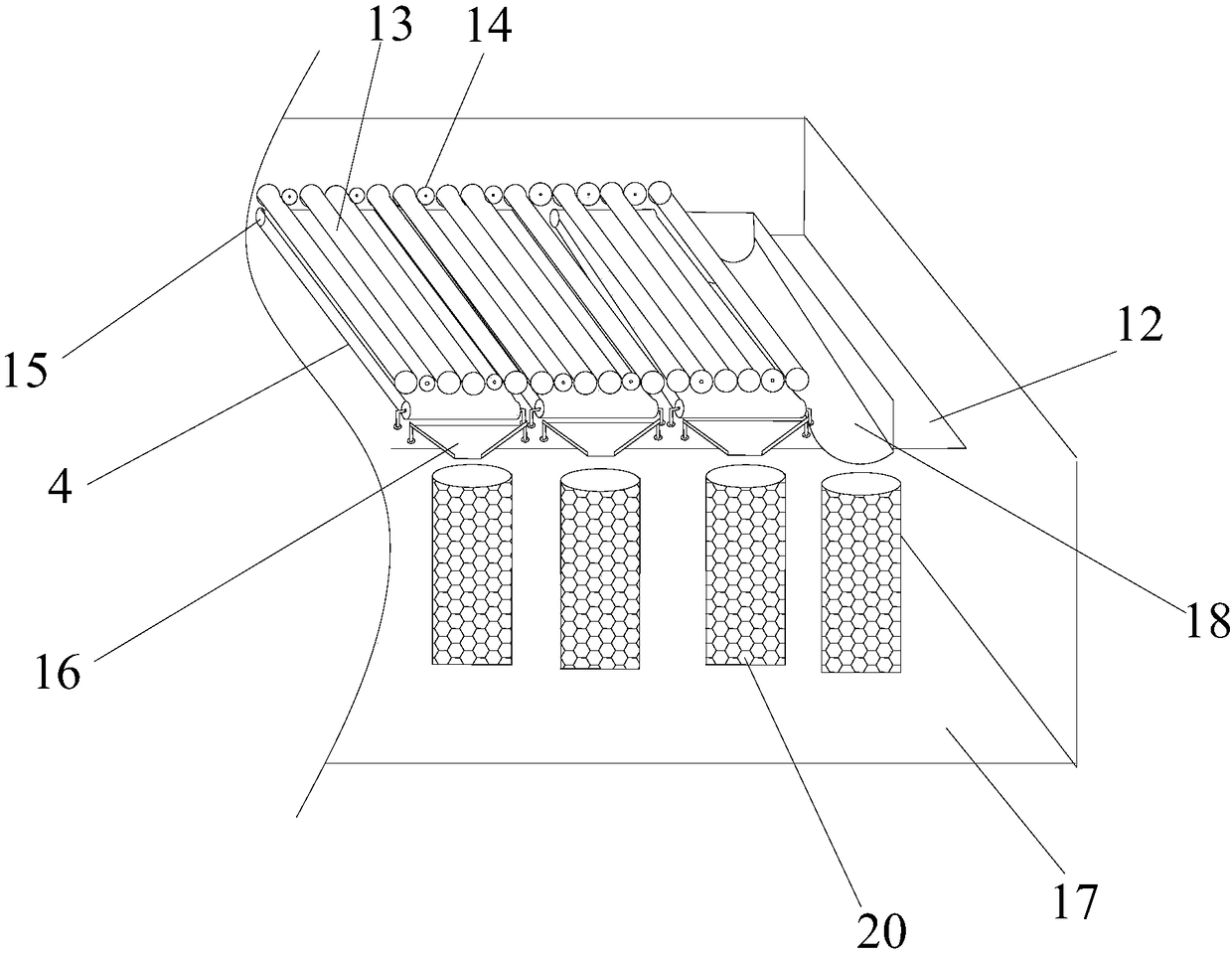

[0022] Combine below figure 1 and figure 2 , a specific embodiment of the present invention will be described in detail, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0023] The potato picking and grading combine harvester provided by the embodiment of the present invention includes: a car body and a control system, and the car body is provided with a picking device, a soil and potato separating device and a potato block lifting device in sequence from front to back, and the soil The potato separation device and the potato piece lifting device are respectively connected with the control system, and the car body is also provided with: a potato piece grading device and a potato piece collecting device; the potato piece grading device and the potato piece collecting device are located in the compartment 17 of the car body, and the potato piece The block grading device is next to the potato block lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com