Intelligent sorting system applied to fruits and vegetables

A sorting system, fruit and vegetable technology, applied in the field of agricultural equipment, can solve problems such as reducing the production efficiency of enterprises, increasing time costs, etc., and achieve the effects of saving drying time, improving production efficiency, and accelerating water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

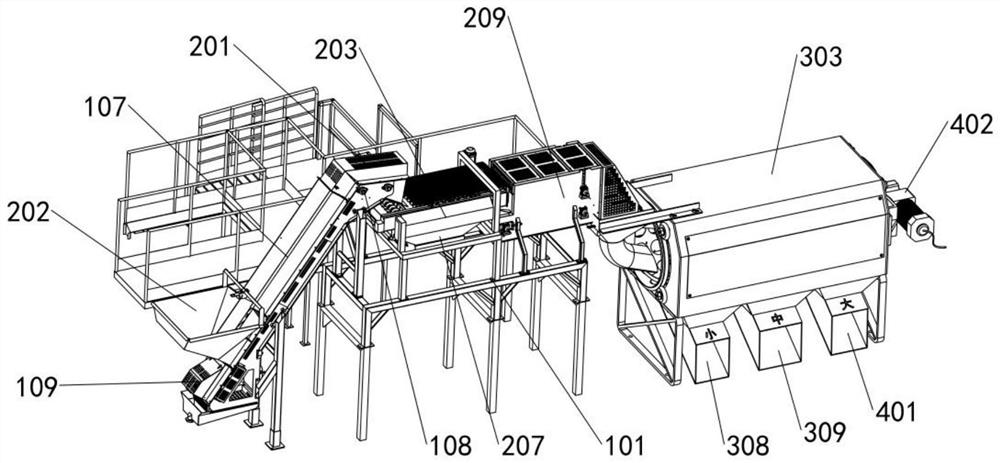

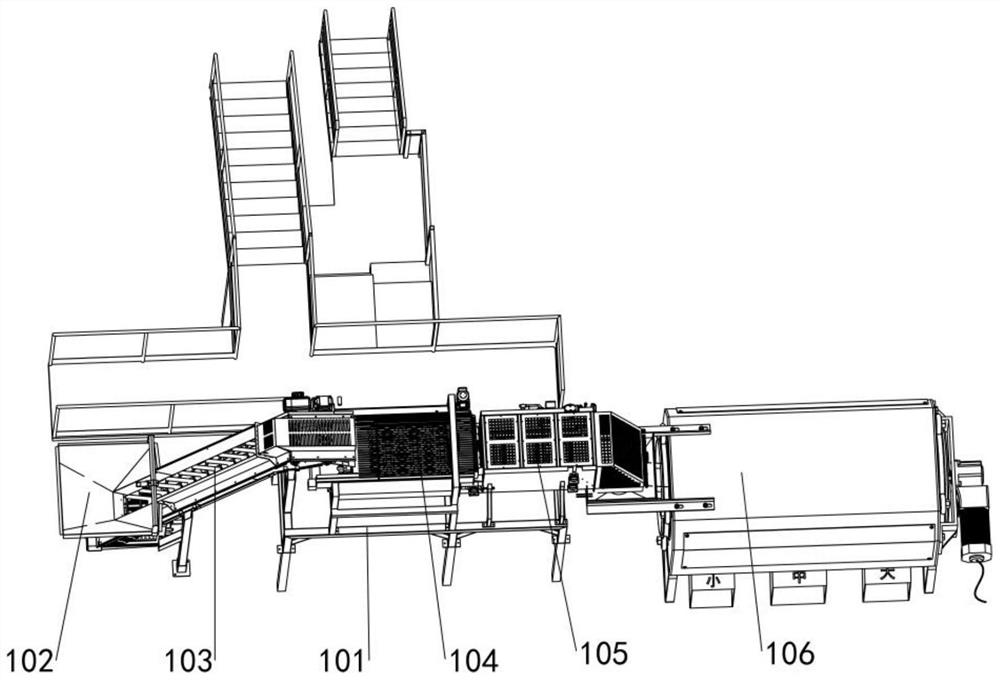

[0044] The first aspect of the present invention provides an intelligent sorting system applied to fruits and vegetables, including a mounting frame 101 and a sorting component installed on the mounting frame 101 .

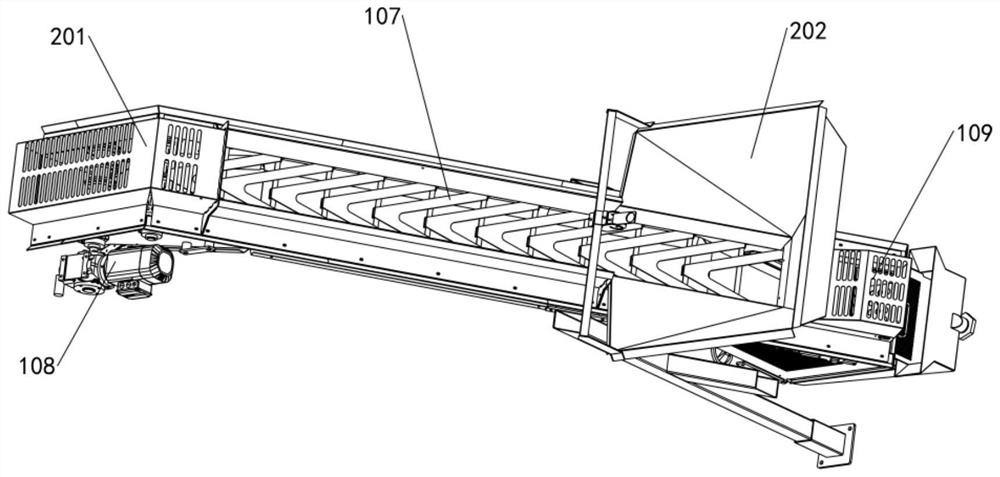

[0045] like figure 1 , 2 , 3, the sorting assembly includes a feeding mechanism 102, a conveying mechanism 103, a cleaning mechanism 104, a drying mechanism 105, and a screening mechanism 106, and the conveying mechanism 103 includes a conveyor belt 107 and a conveyor belt 107 that drives the movement First motor 108, one end of the conveyor belt 107 is provided with a collection bin 109, and the other end is provided with a discharge chamber 201, the collection chamber is connected with the feeding mechanism 102, and the discharge chamber 201 is connected with the feeding mechanism 102. The above-mentioned cleaning mechanism 104 is matched and connected.

[0046] The feeding mechanism 102 includes a feed hopper 202, the feed hopper 202 is arranged in a trapezoi...

Embodiment 2

[0065] The second aspect of the present invention provides a control method for an intelligent sorting system applied to fruits and vegetables, which is applied to any one of the intelligent sorting systems applied to fruits and vegetables, including the following steps:

[0066] Pour the fruits and vegetables into the feeding mechanism, the second sensor senses the information of the fruits and vegetables and feeds back the information, the control system controls the first motor to start to drive the conveyor belt to move;

[0067] The conveyor belt drives the fruits and vegetables into the cleaning chamber. The first sensor senses the information of the fruits and vegetables and feeds back the information. The control system controls the second motor to start to drive the friction wheel to rotate through the rotating shaft. The fruits and vegetables roll forward under the action of the friction wheel, and at the same time turn on the nozzle To spray water on rolling fruits a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com