Vertical quenching furnace

A quenching furnace, vertical technology, applied in the field of heat treatment equipment, can solve the problems of affecting the quenching effect, poor sealing performance of the furnace door, poor temperature balance of the quenching furnace, etc. Good temperature balance and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

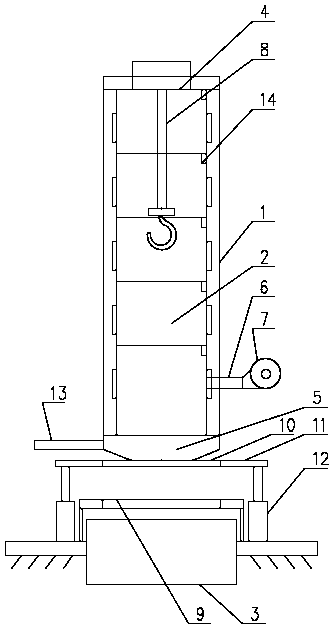

[0018] like figure 1 As shown: the vertical quenching furnace of this embodiment includes a furnace body 1, a heating chamber 2 is arranged inside the furnace body, a quenching pool 3 is arranged under the furnace body, and a furnace cover 4 is arranged on the top of the heating chamber , the bottom of the heating chamber is provided with a furnace door 5, the lower part of the heating chamber communicates with the fan 7 through the air duct 6, the inside of the furnace body is provided with a hoist 8, and a furnace door track 9 is provided below the furnace door. Both sides of the furnace door are respectively provided with two sliding bars 10 that can slide in the track of the furnace door. A hydraulic cylinder 12 is installed below, the piston rod of the hydraulic cylinder withstands the straight arm, an asbestos seal is arranged between the furnace door and the furnace body, and a pull rod 13 is connected to the bottom of the furnace door. The furnace door of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com