Thermal insulation tube clamping lock

A heat preservation pipe and card lock technology, which is applied in the direction of heat preservation, pipe protection through heat insulation, pipe protection, etc., can solve the problems of large randomness, lack of standardization, and increased cost, and achieve easy promotion and popularization of use, appearance Beautiful and tidy, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

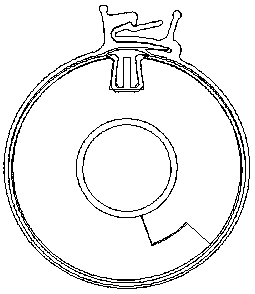

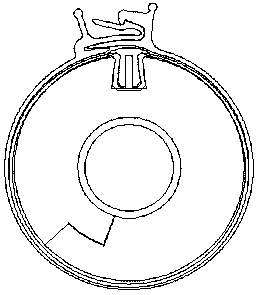

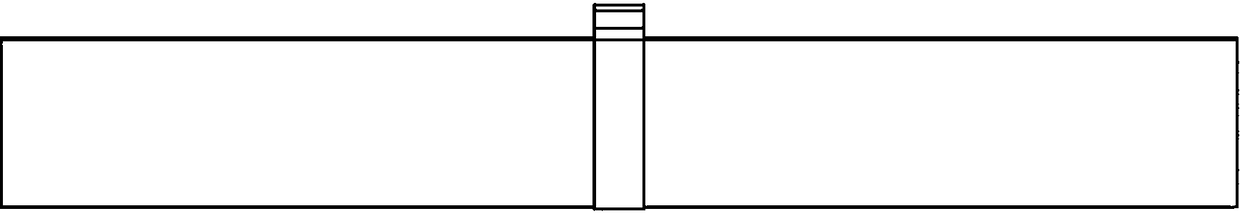

[0023] The insulation pipe latch 10 is injection-molded from high-density polyethylene raw materials, the fixed lock hook 2 and the spring lock hook 1 cooperate, the S-shaped joint groove 4 cooperates with the S-shaped joint convex groove 5, and the interspersed boss 6 and interspersed concave Slot 7 cooperates; the left insulation pipe 11 and the right insulation pipe 12 are butted together and then connected by the insulation pipe lock 10 in the middle; when the decoupling handle 9 is pressed down, the spring lock hook 1 and the fixed lock hook 2 are automatically disengaged, and the insulation pipe lock is completed. The disassembly of the lock: when the left handle 3 and the right handle 8 are firmly pressed along the circumferential direction, the spring lock hook 1 and the fixed lock hook 2 will automatically cooperate to complete the locking of the insulation pipe lock 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com