Auscultation ball type gas pipeline leakage detection device and method

A technology for leak detection device and gas pipeline, applied in pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as difficult construction, poor application adaptability, and failure in diagnosis, and achieve reliability and robustness Good, high information redundancy, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

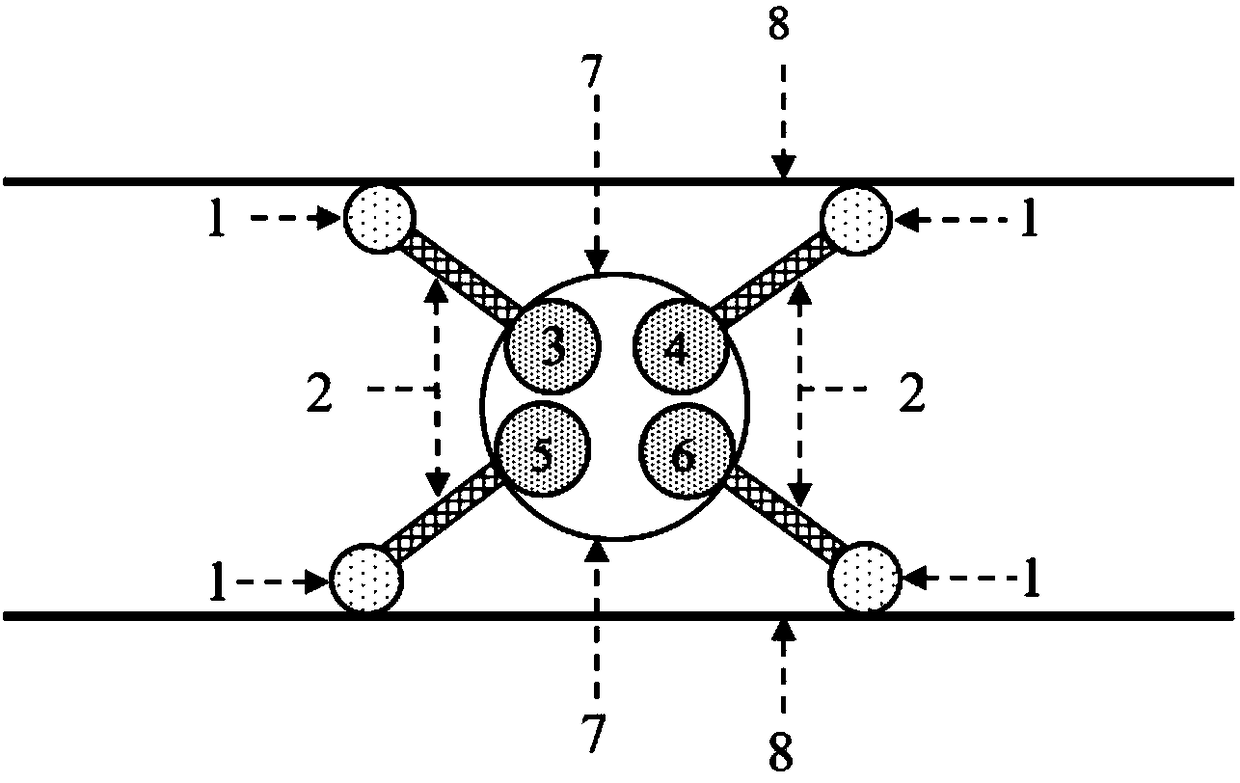

[0033]The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0034] Such as figure 1 As shown, a kind of auscultation ball type gas pipeline leak detection device of the present invention comprises auscultation head 1, sound guide tube 2, auscultation ball 7 and acoustic emission sensor, and in the present embodiment, auscultation head 1, sound guide tube 2 and acoustic emission There are four groups of sensors, or three or more groups. The four acoustic emission sensors are acoustic emission sensor 1#3, acoustic emission sensor 2#4, acoustic emission sensor 3#5 and acoustic emission sensor 4#6, and the acoustic tube 2 is installed on the auscultation head 1 with the same specification. The other end of the acoustic tube 2 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com