Automatic size and putting position calculation method and device, equipment and medium

A technology of placement and automatic calculation, applied in the direction of calculation, design optimization/simulation, special data processing applications, etc., can solve the problems of cumbersome operation of measuring tools, cumbersome operation, purchase of standard parts, etc., to save manpower and material resources, avoid Errors, reduce the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

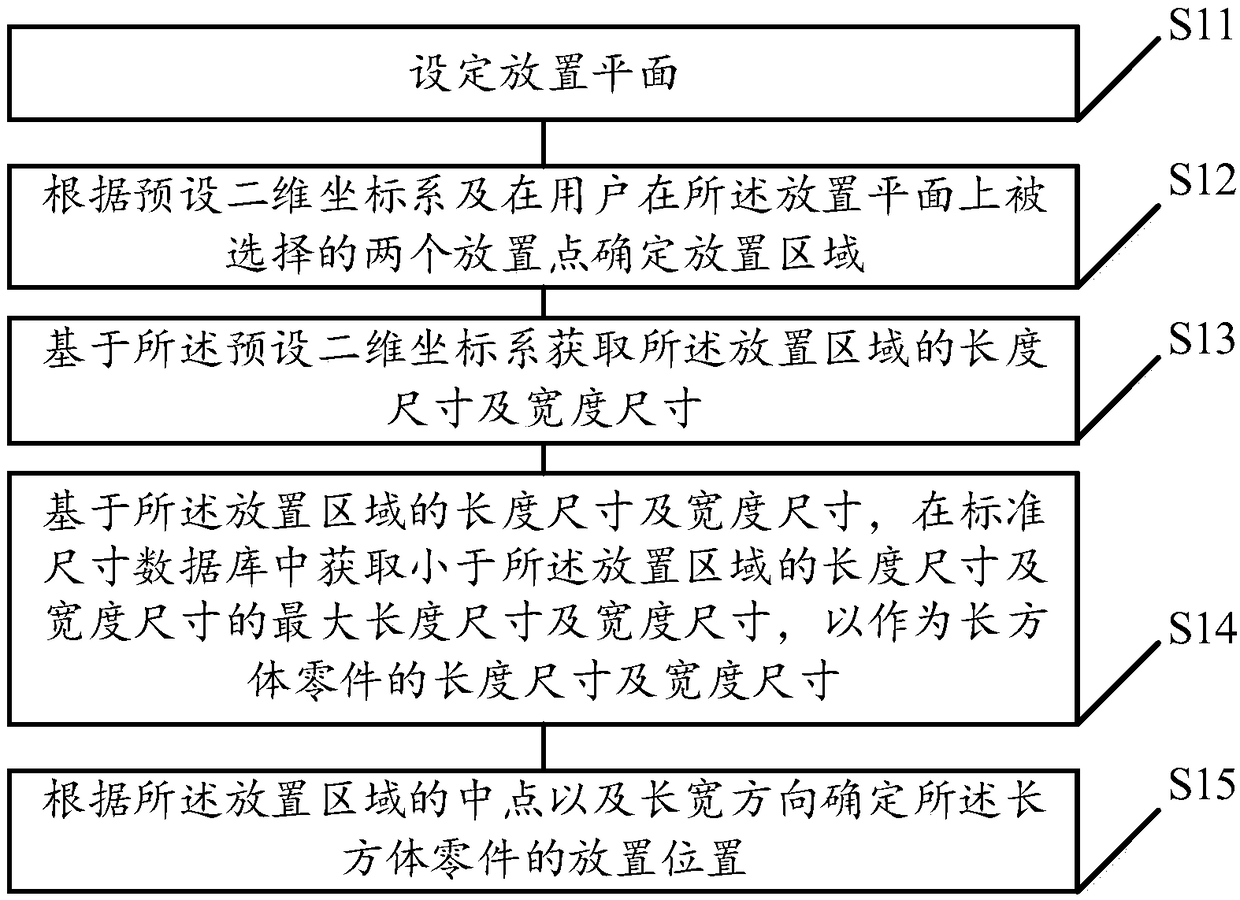

[0054] On the basis of the first embodiment of the present invention, it also includes:

[0055] According to the obtained length dimension and width dimension of the cuboid part, the first height dimension corresponding to the length dimension and width dimension is obtained from the standard dimension database.

[0056] In the embodiment of the present invention, after the terminal device acquires the length dimension and width dimension corresponding to the cuboid part from the standard dimension database, it acquires the first height dimension corresponding to the length dimension and width dimension, so as to avoid the The length and width dimensions correspond to multiple height values and cannot determine the length and width dimensions.

no. 3 example

[0058] On the basis of the second embodiment of the present invention, it also includes:

[0059] Draw a model corresponding to the cuboid part in the placement area according to the length dimension, width dimension, and width dimension of the cuboid and the placement position of the cuboid part.

[0060] In the embodiment of the present invention, the terminal device draws a three-dimensional wireframe model corresponding to the cuboid part in the placement area according to the length dimension, width dimension, width dimension and the placement position of the cuboid part , at the same time, the midpoint of the placement area is used as the base point position of the cuboid part, and a three-dimensional dynamic coordinate system is displayed on the base point position, and the position of the corresponding axis can be adjusted by dragging the xyz axis of the coordinate system with the mouse for the dynamic coordinate system . It should be noted that when drawing the cuboi...

no. 4 example

[0062] On the basis of the third embodiment of the present invention, it also includes:

[0063] At the positions of the sides corresponding to the length, width and height of the drawn cuboid part model, drag bars for dynamically editing dimensions corresponding to the length, width and height of the cuboid are respectively displayed.

[0064] In the embodiment of the present invention, the terminal device displays the dynamic editing size support bars corresponding to the length, width and height respectively at the side positions of the length, width and height of the drawn cuboid model, so that the user can The direct touch of the device on the touch-sensitive surface can drag the dynamic editing size drag bar to dynamically modify the length, width and height dimensions corresponding to the cuboid part model, which is convenient for the user to modify the drawn cuboid part model in real time and improves the user's usability. experience.

[0065] see Figure 4 , the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com