Special label for cylindrical tubing couplings and mounting method thereof

A label and tubing technology, which is applied in the field of special labels for cylindrical tubing couplings and their installation, can solve the problems of surface corrosion and wear, error-prone, slow recognition speed, etc., to ensure position stability, novel structural design, and prevent falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 A Special Label for Cylindrical Tubing Couplings

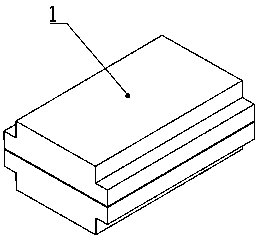

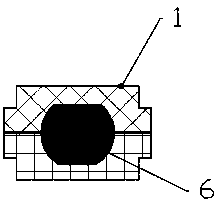

[0031] Such as Figure 1-5 In the shown embodiment 1, a special label for a cylindrical oil pipe coupling includes a label packaging material and label internal components arranged on the substrate mounting surface 2, and the label internal components include a substrate 3, an RFID integrated circuit and a chip 4 and the antenna 5, the internal components of the label are encapsulated into a columnar structure package 6 through injection molding or assembly through packaging materials, the side of the columnar structure package 6 is processed with a plane, and the substrate mounting surface 2 is arranged on the columnar structure package 6, and forms an acute or obtuse angle with the axial direction of the cylindrical structure package 6, the substrate 3 is mounted on the substrate mounting surface 2, and the RFID integrated circuit, the chip 4 and the antenna 5 are deployed on the substrate 3. The oil pipe c...

Embodiment 2

[0033] Example 2 A Special Label for Cylindrical Tubing Couplings

[0034] Such as Figure 6 In the shown embodiment 2, a special label for a cylindrical oil pipe coupling includes a label packaging material and label internal components arranged on the substrate mounting surface 2, and the label internal components include a substrate 3, an RFID integrated circuit and a chip 4 and the antenna 5, the internal components of the label are encapsulated into a columnar structure package 6 through injection molding or assembly through packaging materials, the side of the columnar structure package 6 is processed with a plane, and the substrate mounting surface 2 is arranged on the columnar structure package 6, and forms an acute or obtuse angle with the axial direction of the cylindrical structure package 6, the substrate 3 is mounted on the substrate mounting surface 2, and the RFID integrated circuit, the chip 4 and the antenna 5 are deployed on the substrate 3. The oil pipe cou...

Embodiment 3

[0036] Example 3 A Special Label for Cylindrical Tubing Couplings

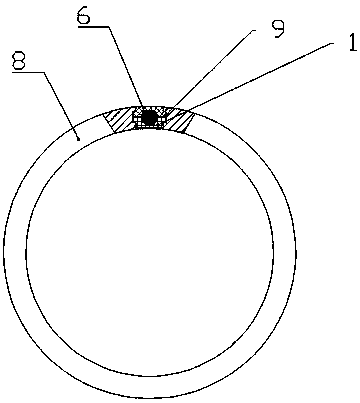

[0037] Such as Figure 7 In the shown embodiment 3, a special label for a cylindrical oil pipe coupling includes a label packaging material and label internal components arranged on the substrate mounting surface 2, and the label internal components include a substrate 3, an RFID integrated circuit and a chip 4 And the antenna 5, the internal components of the tag are encapsulated into a pin-shaped structure package 7 by means of injection molding or assembly as a whole, and the substrate mounting surface 2 is arranged in the middle of the pin-type structure package 7, and is connected to the pin-type structure package 7 The direction of the axis is at an acute or obtuse angle, the substrate 3 is mounted on the substrate mounting surface 2 , and the RFID integrated circuit, the chip 4 and the antenna 5 are arranged on the substrate 3 . The oil pipe coupling 8 for installing the special label is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com