Novel amorphous silicon thin-film battery equipment

An amorphous silicon thin film and battery technology, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve problems such as inaccurate installation and positioning, affecting product quality, and inability to effectively remove impurities, achieving convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

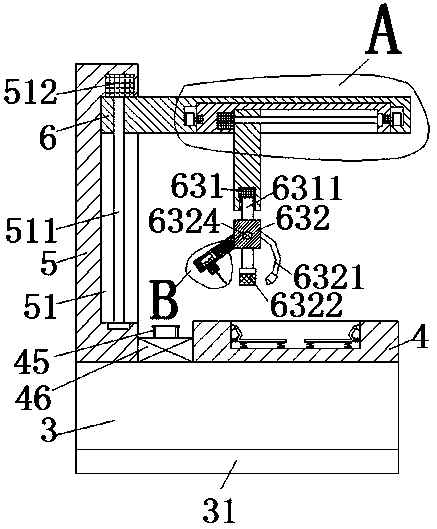

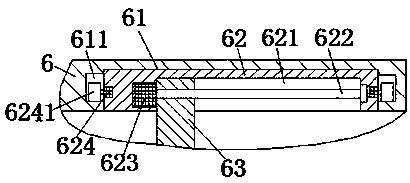

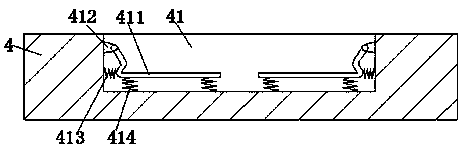

[0015] Such as Figure 1-Figure 5 As shown, a new type of amorphous silicon thin film battery equipment of the present invention includes a bottom plate 3 and a lifting seat 5 arranged on the left side of the top end surface of the bottom plate 3 and a fixing seat 4 arranged on the right side of the top end surface of the bottom plate 3 , The bottom end surface of the bottom plate 3 is glued and installed with a plastic backing plate 31, the right end surface of the lifting seat 5 is provided with a first guide groove 51, and a support plate 6 is slidably connected in the first guide groove 51, The right end of the supporting plate 6 extends out of the first guide groove 51 and is located above the setting seat 4. The supporting plate 6 in the first guide groove 51 is connected to the inner thread of the supporting plate 6 extending up and down. The first threaded rod 511, the bottom extending end of the first threaded rod 511 is rotatably connected with the bottom inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com