Machining tool

A technology of cutting tools and cutting tools, which is applied in the field of cutting tools, can solve problems such as poor and smooth operation, and achieve the effect of reducing vibration excitation and improving smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

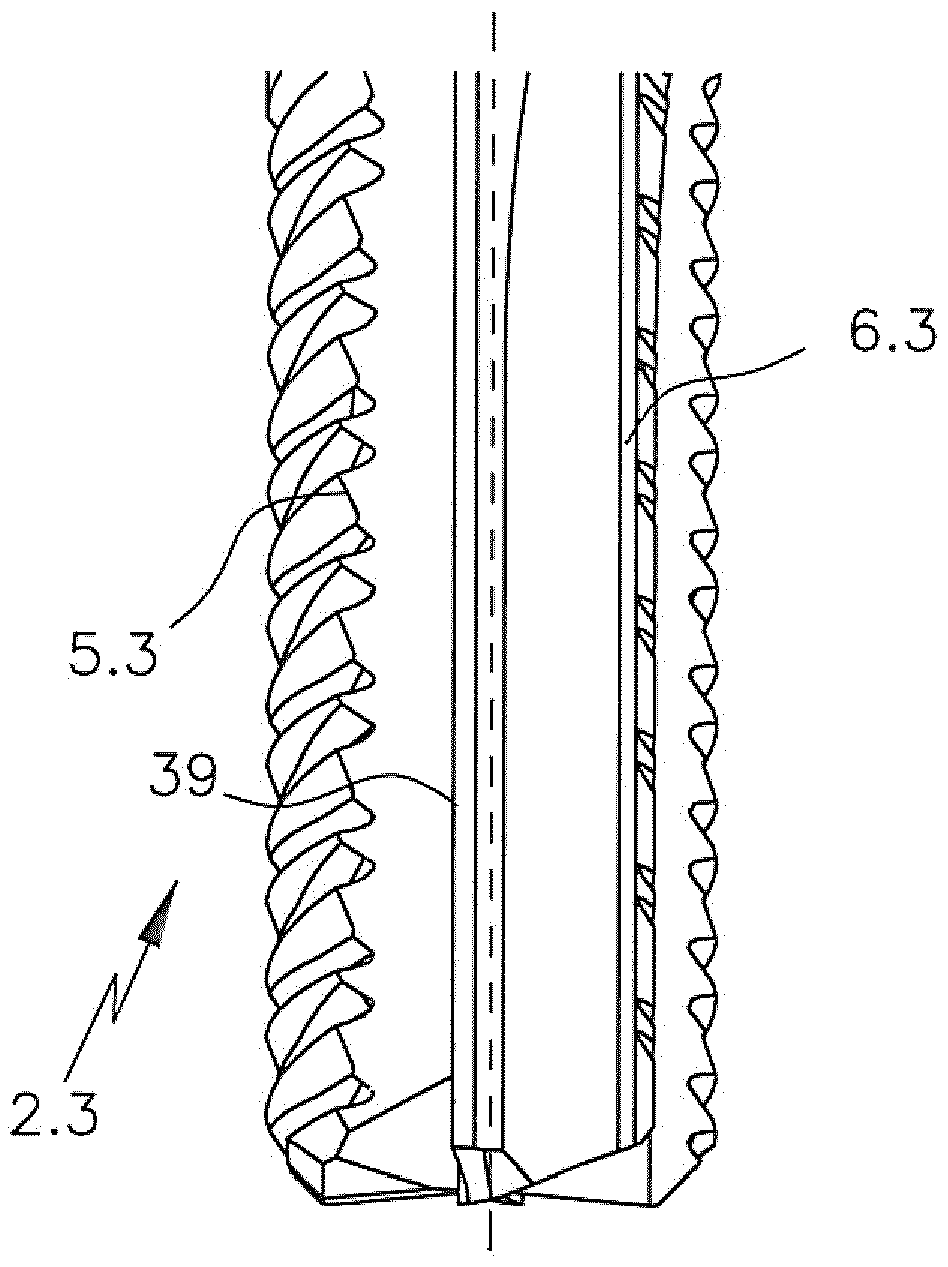

[0029] figure 1 The cutting edge section 1.1 of the cutting tool 2 is shown. A further section 1.2 is attached to the cutting edge section 1.1 from above, with which the cutting tool 2 can be clamped.

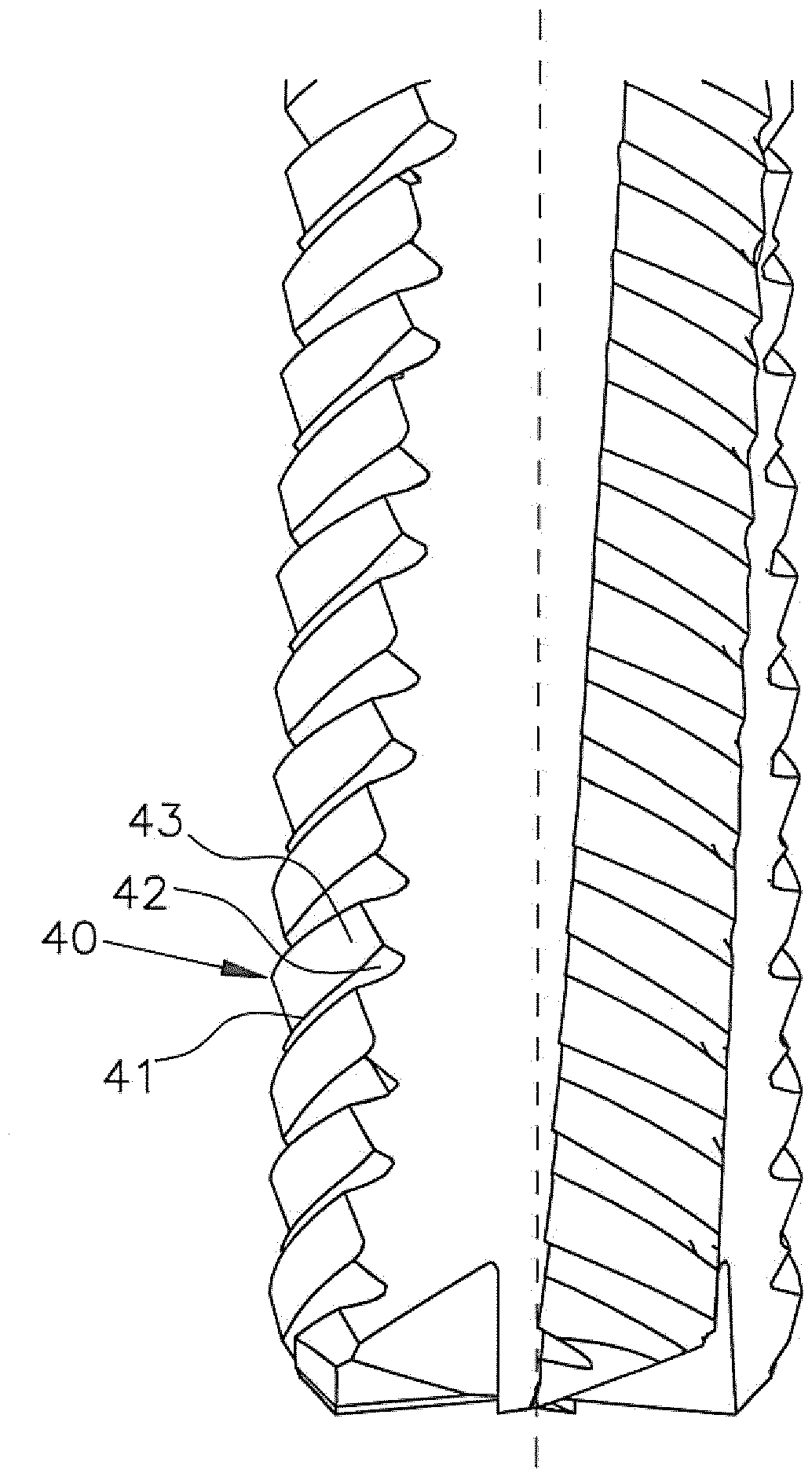

[0030] The cutting tool 2 is designed approximately cylindrically. It has cutting grooves 3, 4 which space the edges 5, 6, 7 from each other. According to the edger 5 , the edger 5 to 7 has a cutting edge 10 on the peripheral side. The cutting edges 10 are spaced apart from each other by grooves 11 .

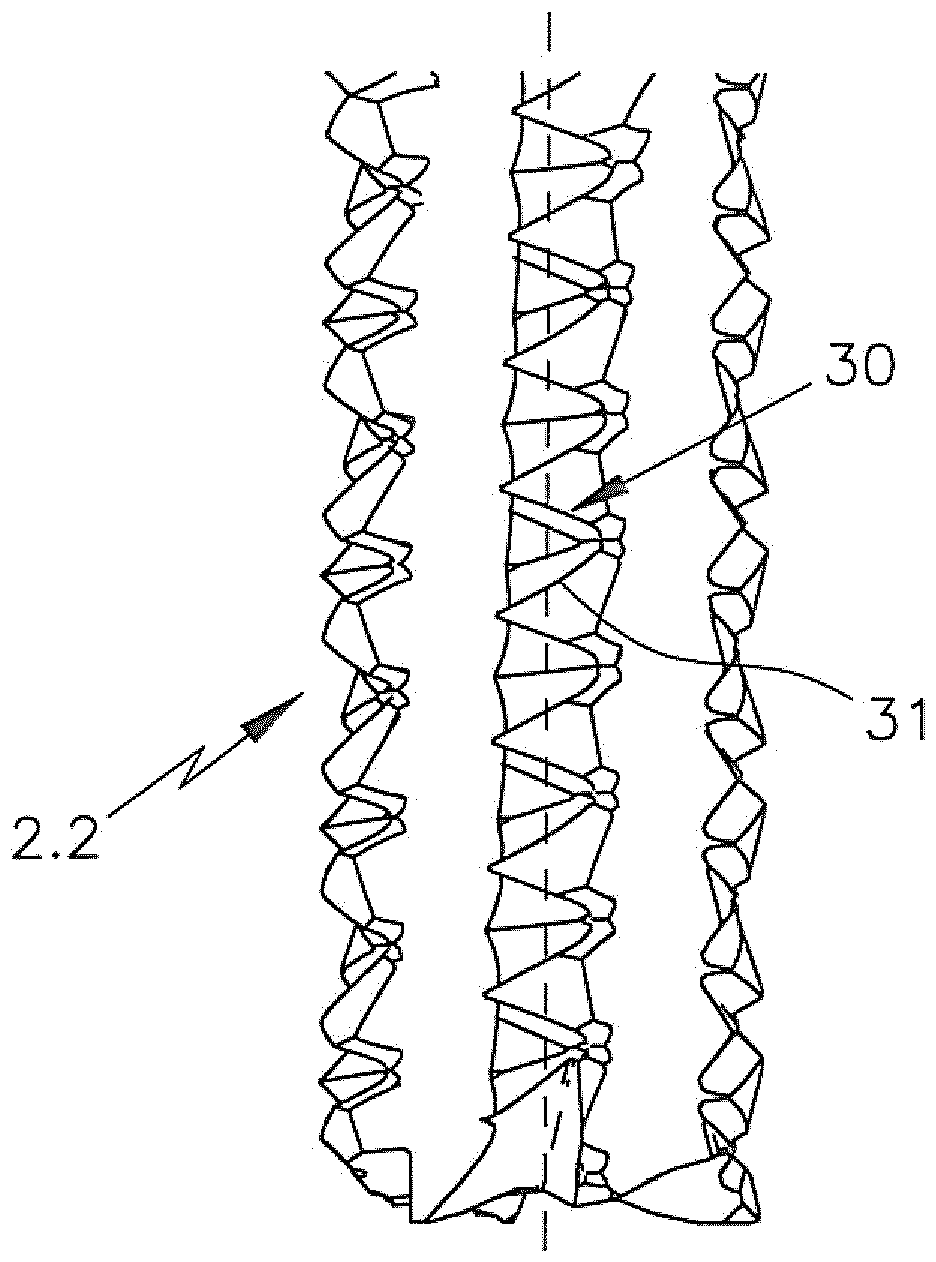

[0031] figure 2 The unwinding of the cutting edge, for example the cutting edges 13 , 14 of the cutting edge 10 , is shown. The cutting edges 14 have positive helix angles a1, a2, an. This means that the angles a1 , a2 , an are positive relative to the longitudinal axis 2 of the cutting tool 2 . All cutting edges with their associated cutting edges 14 have different helix angles a1 , a2 , an. This means, a1≠a2≠an.

[0032] The cutting edge with the cutting edge 13 corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com