Vibration reduction in an exhaust gas turbo-supercharger

A technology of exhaust gas turbine and supercharger, which is applied in the direction of gas turbine devices, machines/engines, blade support components, etc. It can solve the problems of affecting the speed range, increasing the material load of noise generation structure collapse, reducing efficiency, etc., to achieve improvement Effects of thermodynamic parameters, avoiding resonance, improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

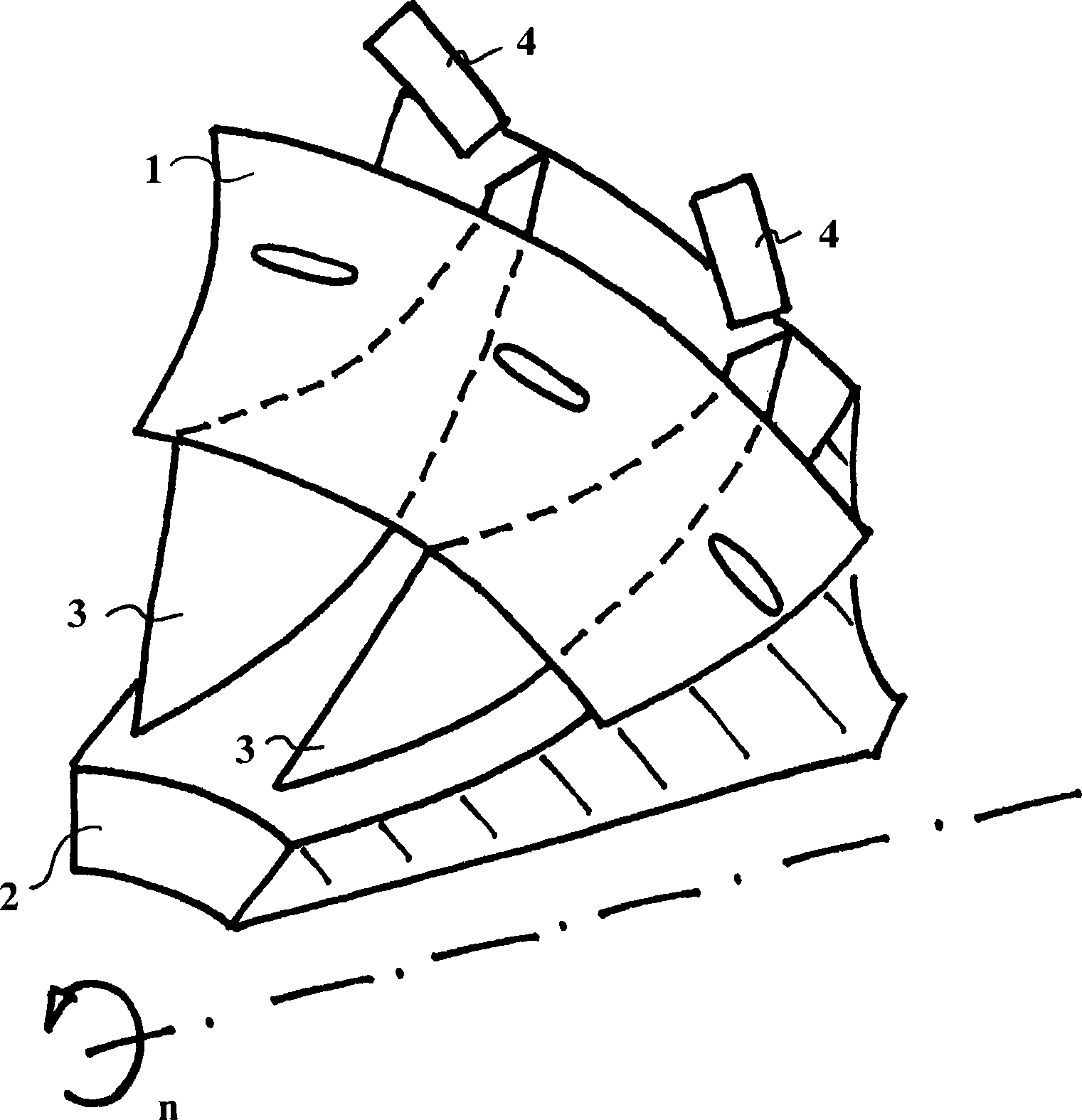

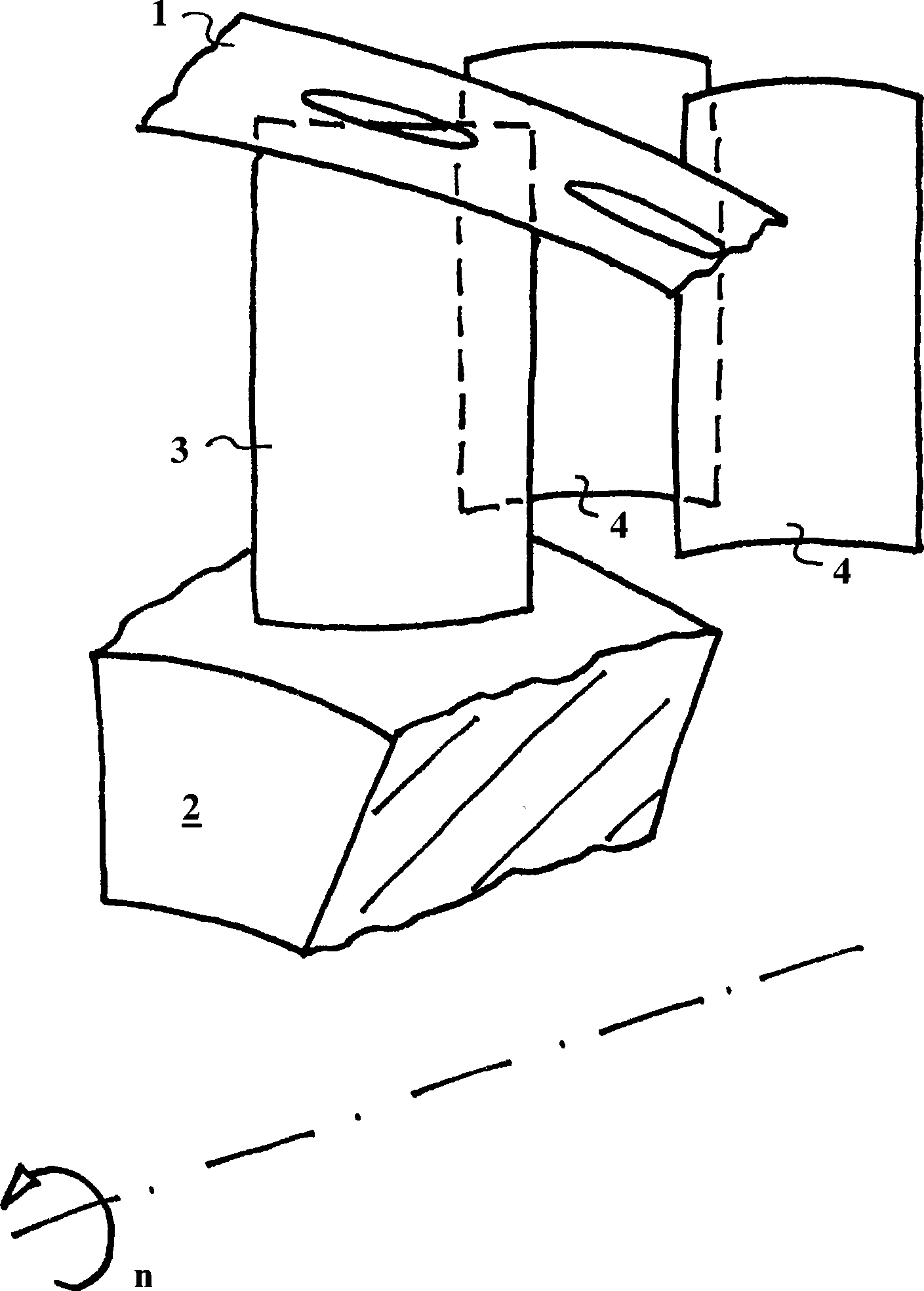

[0030] figure 1 The figure shows a radial compressor according to the invention of an exhaust gas turbocharger for a marine diesel engine in section in a perspective view.

[0031] The impeller hub or rotor hub 2 is accommodated in the housing 1 in such a way that a flow channel for the combustion air for the marine diesel engine is defined between them. Arranged in this flow channel are the rotor blades 3 for acceleration and deflection of the air, which rotate together with the rotor hub 2 at a rotational speed n around the longitudinal axis of the compressor and supply the air to the rear guide arranged downstream. Guide vanes 4, in the rear guide, the kinetic energy of the air is partially converted into pressure energy.

[0032] Turbulences in the form of pressure and velocity fluctuations are induced in the air flow by the guide vanes 4 , which act on the rotor blades 3 . Since the rotor blades are thin-walled and thus have a low bending stiffness, the rotor blades are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com