Low-noise crankshaft buffer mechanism and engine

A buffer mechanism and low-noise technology, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of increasing production management costs and inability to completely eliminate gaps, achieve low maintenance costs in the later stage, and improve axial movement. , Improve the effect of the axial movement of the crankshaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

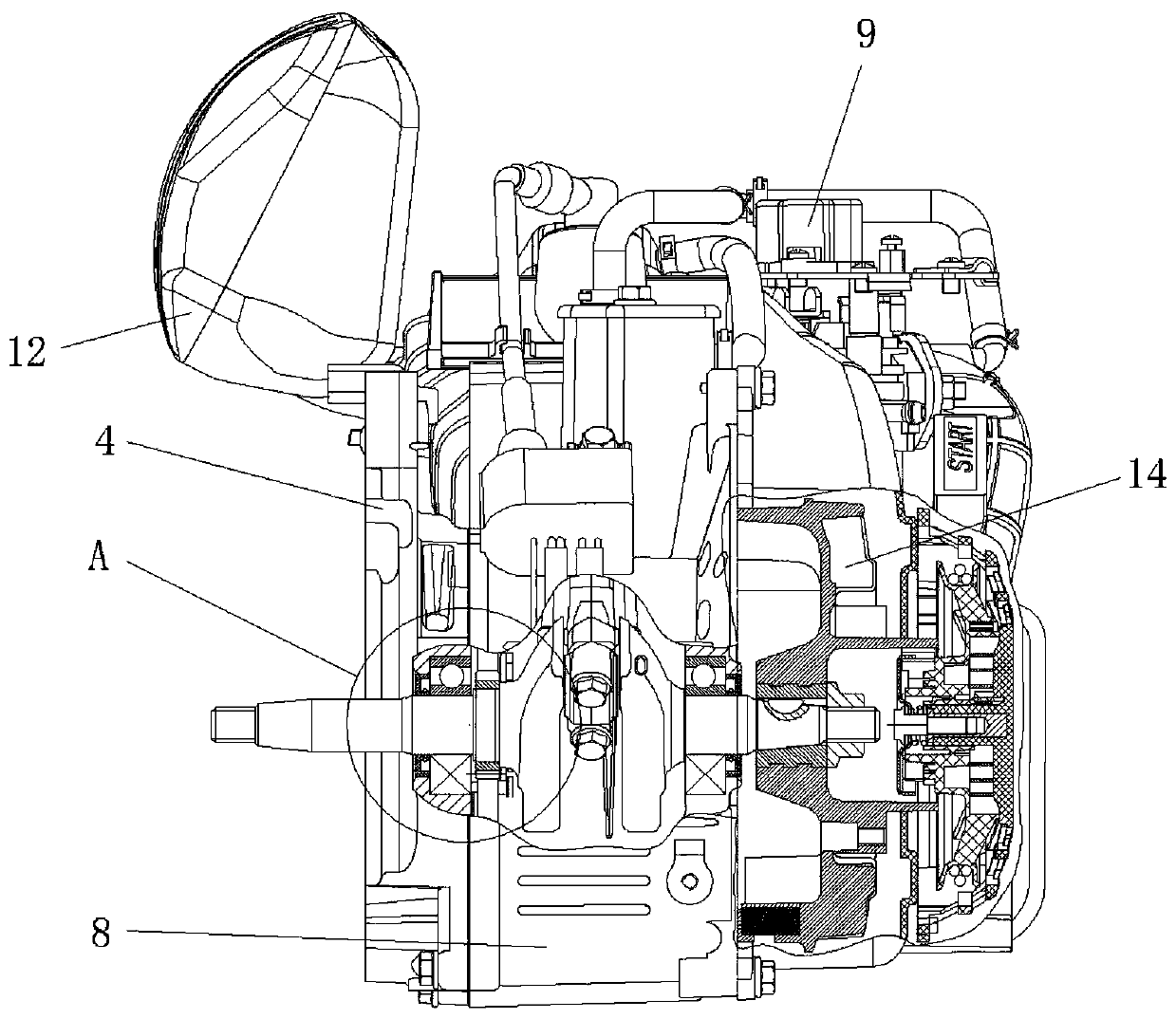

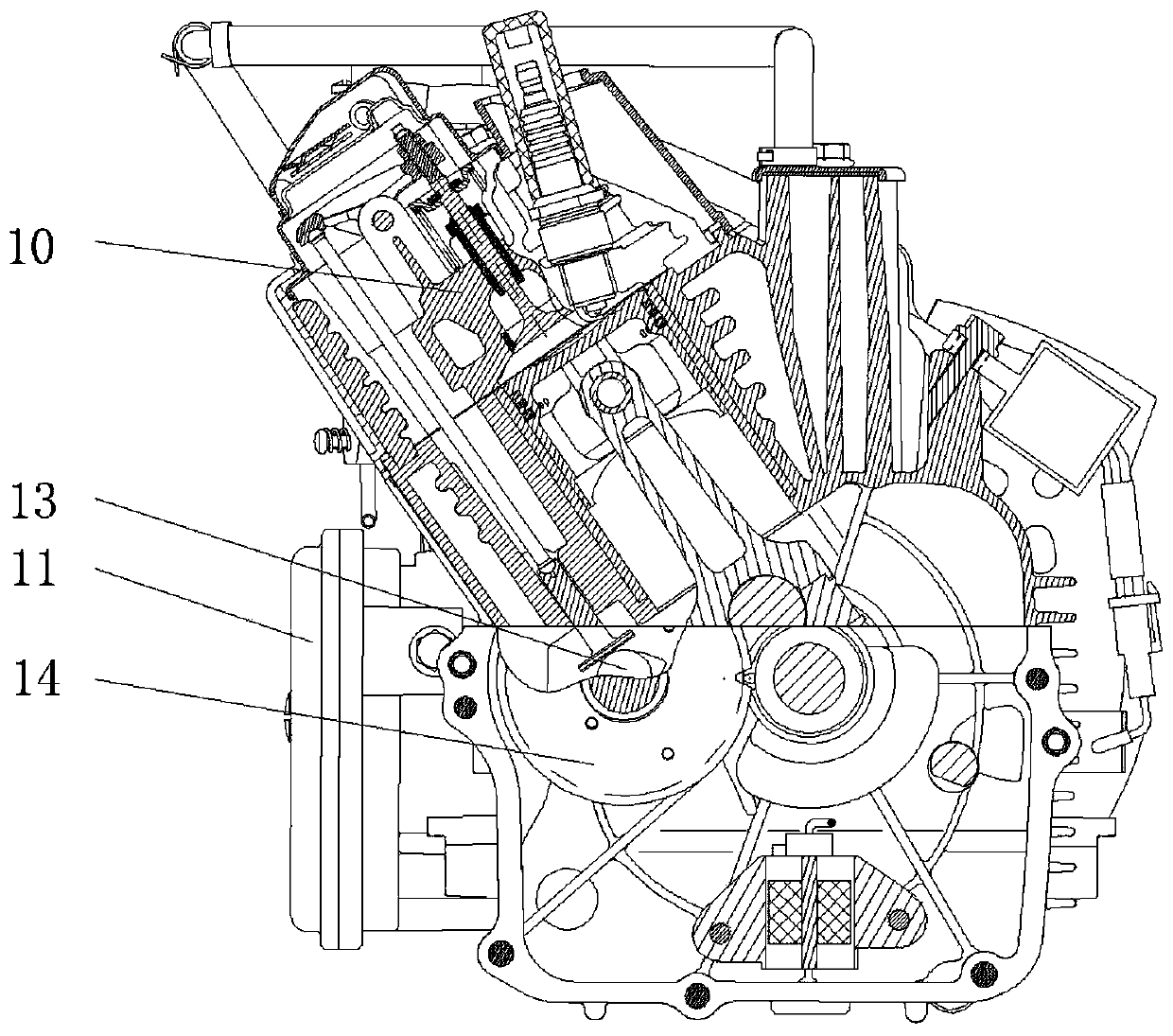

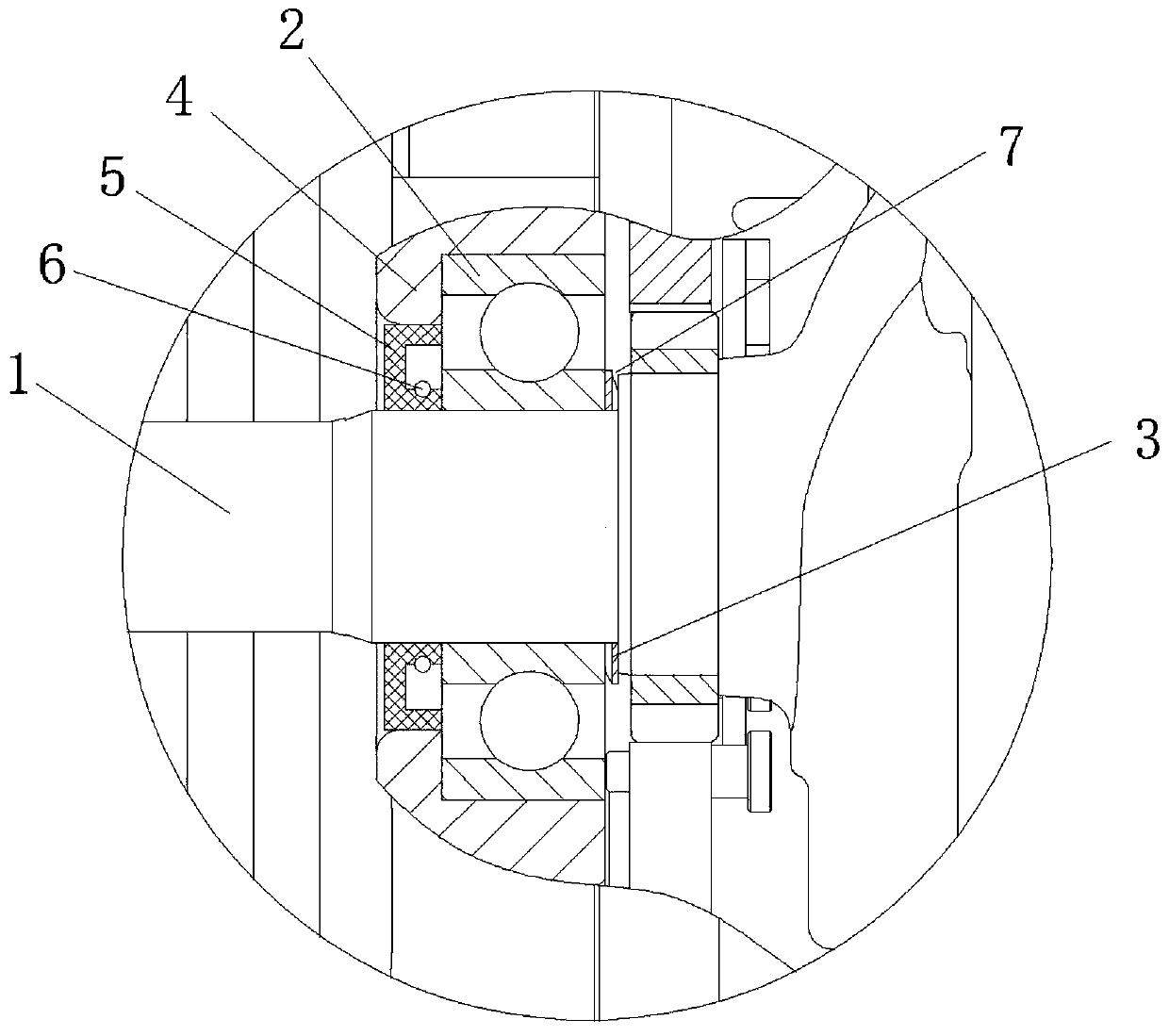

[0022] figure 1 A schematic diagram of the engine structure; figure 2 Schematic diagram of the sectional structure of the engine; image 3 for figure 1 Schematic diagram of the enlarged structure at point A;

[0023] This embodiment provides a low-noise crankshaft buffer mechanism. There is a gap 7 in the axial direction between the bearing 2 at at least one end of the crankshaft 1 and the corresponding shoulder, and an elastic member 3 is arranged in the gap. When the crankshaft is normally assembled, both ends of the crankshaft are equipped with bearings, and both ends of the crankshaft are of stepped shaft structure, in which the bearing is sleeved on the small diameter section, and the inner side of the bearing is pressed against the shaft shoulder to form axial positioning, and the bearing passes through the crankshaft The box cover and the corresponding shaft shoulder realize the positioning on both sides of the axial direction, and the inner side of the bearing repr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com