Laminated packaging material, packaging containers manufactured therefrom

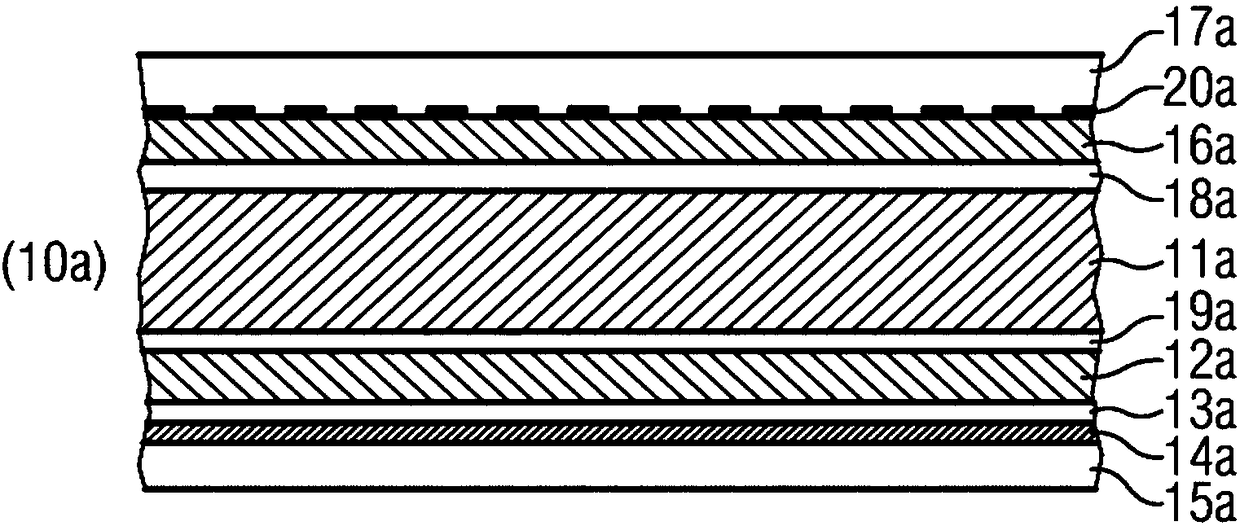

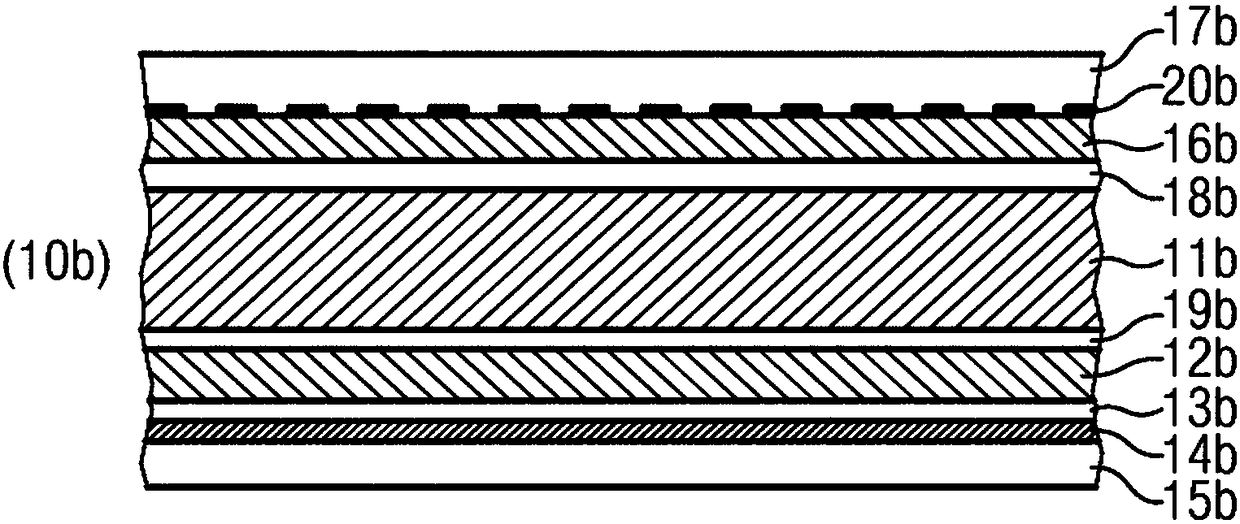

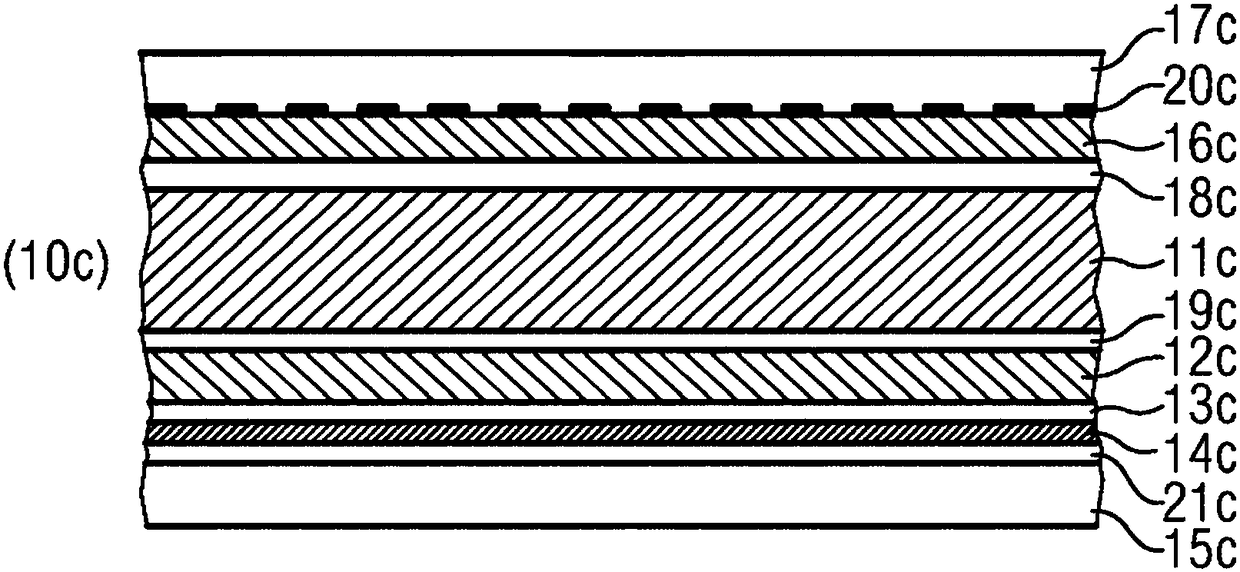

A technology for packaging materials and packaging containers, applied in the field of packaging containers for liquid food packaging, laminated packaging materials, and the manufacture of such laminated packaging materials, which can solve the less favorable, important properties of mechanical strength and packaging integrity, and material barriers Performance impairment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0212] Example 1: / / LDPE / 200g / m 2 Corrugated paper / LDPE / aluminum foil 6μm / EAA / blend LDPE+mLLDPE /

[0213] exist Figure 6 , it is shown that OTR of metallized layers / coatings can be further improved in combination with extrusion coating / lamination of metallized barrier layers onto adhesive polymers such as EAA. Such effects of course come in handy when the barrier properties of metallized materials need to be improved. The specific experiment behind this conclusion is by using two layers of 1g / m 2 PVOH coating of 50 g / m2 thin dual phase paper followed by a metallized coating on PVOH, the metallized coating has an OD (optical density) of about 2. When such a barrier coated paper is laminated to the laminate and laminated to the adjacent layer of the LDPE laminate and the blend of LDPE and metallocene-LLDPE on the inner side, at 23°C and 50% RH oxygen transmission rate becomes almost as high as 10cc / m 2 , 24 hours, 1atm. When laminated in the same way, the metallized layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com