Material-smashing crusher for improving size uniformity

A technology of uniform size and crusher, applied in the field of crushers for material crushing, can solve the problems of affecting crushing quality, uneven crushing size, and inaccurate crushing particle size of materials, so as to improve accuracy, quality and uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

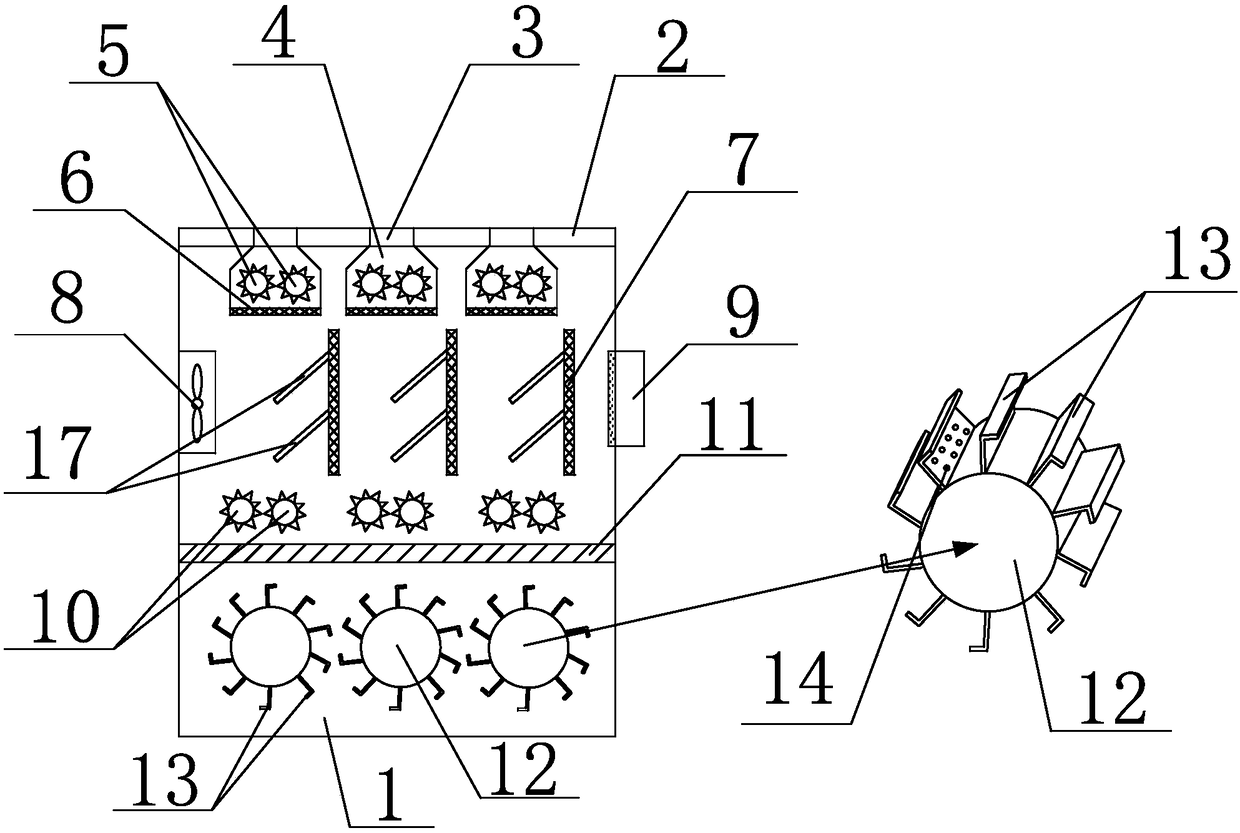

[0025] Such as figure 1As shown, the present invention is used to improve the size uniformity of the material crushing crusher, comprising a crusher body 1, the top opening of the crusher body 1, a feeding plate 2 is installed at the opening, and a plurality of The feed port 3 is connected with the primary crushing chamber 4 below the feed port 3. The primary crushing chamber 4 is provided with a first crushing roller group 5. The bottom of the primary crushing chamber 4 is open and provided with a primary filter 6. The primary crushing chamber 4. There are a plurality of partitions 7 arranged vertically and parallel in the horizontal direction below. A blower 8 is provided on one side of the inner wall of the crusher body 1, and a dust collection device 9 is provided on the other side. Between the blower 8 and the dust collection device 9 The connecting line between them is perpendicular to the partition screen 7; a plurality of second crushing roller groups 10 are arranged u...

Embodiment 2

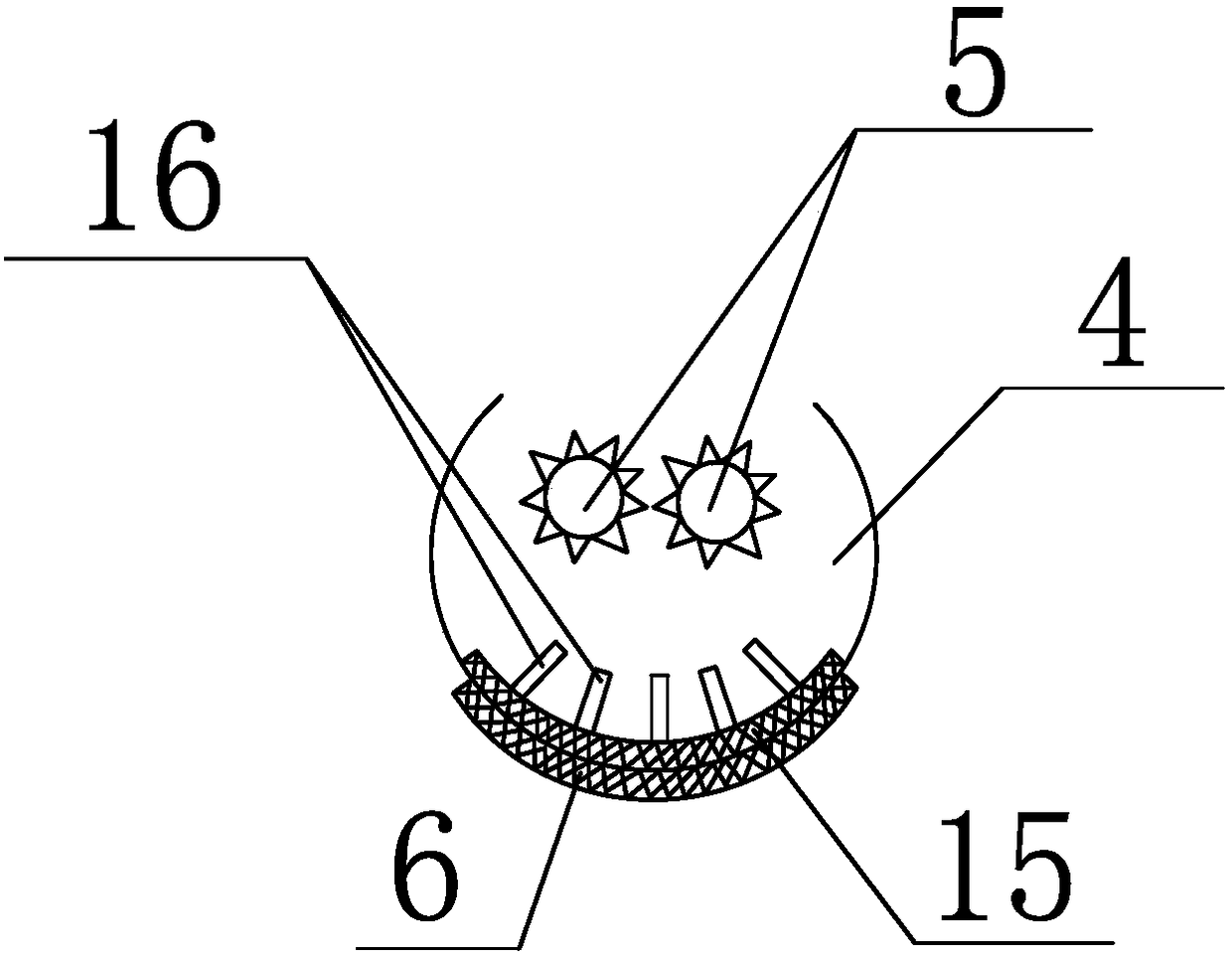

[0031] Such as figure 2 As shown, on the basis of Example 1, the primary crushing chamber described in this embodiment is cylindrical, and the primary filter screen is an arc-shaped filter screen that matches the shape of the cylindrical primary crushing chamber. The sliding screen 15 has the same mesh size as the primary screen and matches the arc shape. The sliding screen can slide along the inner wall of the primary crushing chamber and around the circumference of the cylindrical primary crushing chamber from bottom to top to the first crushing roller. above the group. After the first primary crushing of the material, the material that meets the size passes through the sliding screen and the primary screen for subsequent processing, while the oversized material is left on the sliding screen, so that when the sliding screen accumulates After the amount of large-sized materials reaches a certain level, the sliding screen is driven to slide upward along the inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com