Punching equipment for metallic gaskets

A technology of punching equipment and metal gaskets, which is applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of increasing labor intensity of workers and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the accompanying drawings and embodiments of the description, the specific embodiments of the present invention are described in further detail:

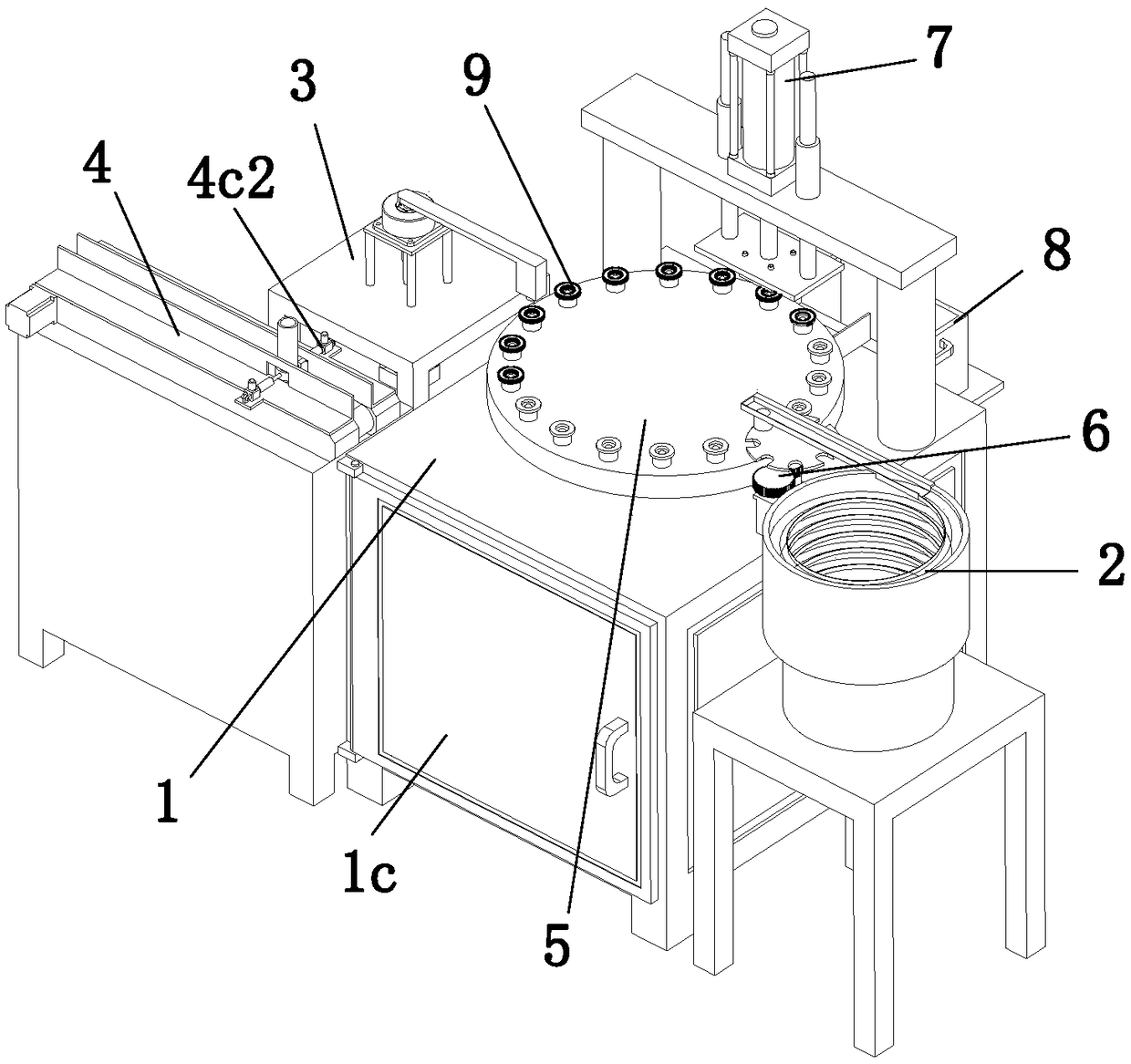

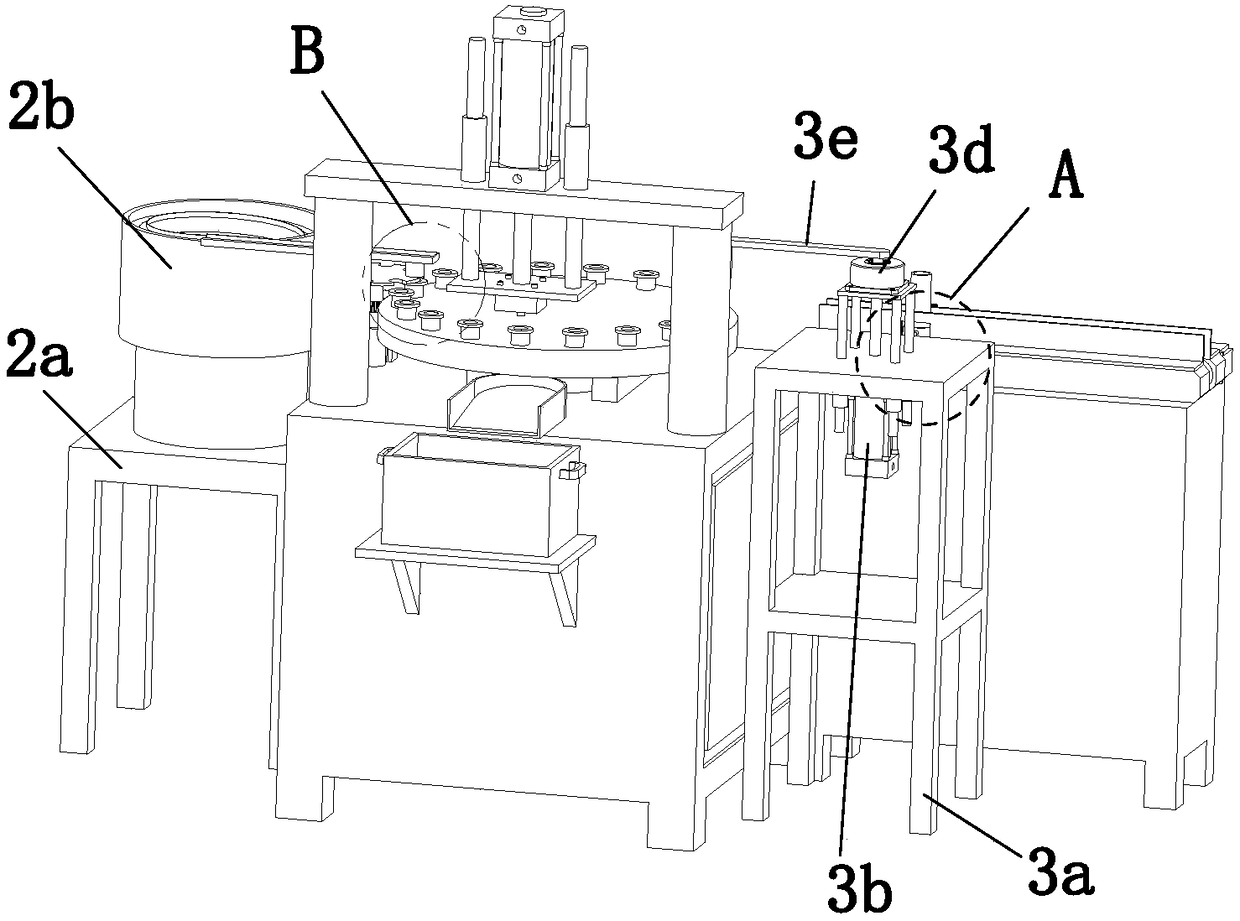

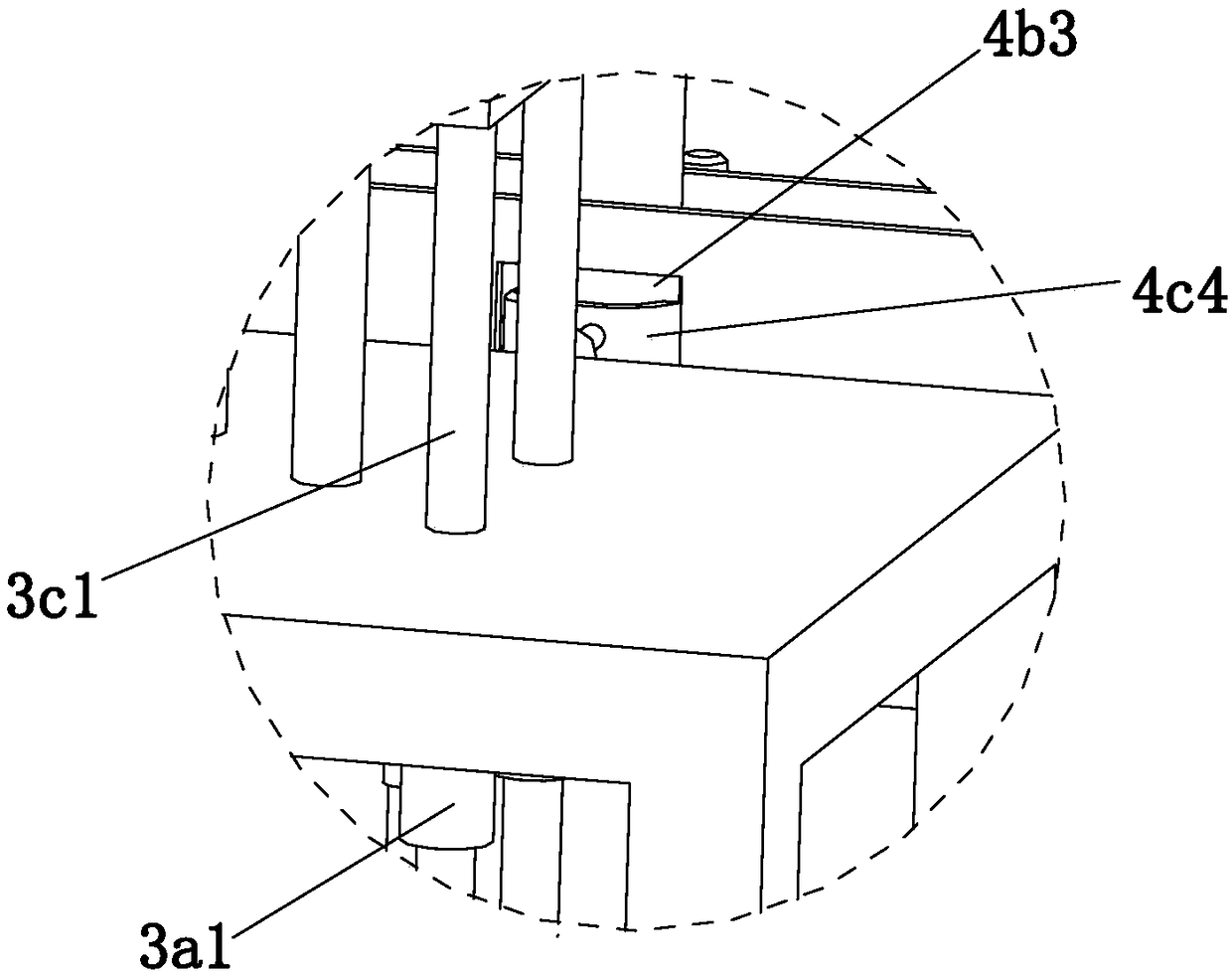

[0030] refer to Figure 1 to Figure 10The shown punching equipment for metal gaskets includes a frame 1, a feeding device 2, a handling device 3 and a feeding device 4. The frame 1 is provided with a turntable 5, a discharging device 6, and a punching device. The device 7 and the waste collection device 8, the turntable 5 is provided with a number of positioning jigs 9 arranged along the circumference of the turntable 5, and each positioning jig 9 on the turntable 5 is provided with the positioning jig 9. The matching blanking hole 5a, the rack 1 is provided with a mounting bracket 1a, the mounting bracket 1a is provided with a stepping motor 1b that drives the turntable 5 to rotate in a step-by-step manner, and the main shaft of the stepping motor 1b is connected to the turntable 5 , the feeding de...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap