Shape cutting process for octahedral arc-shaped sealing head of tank container of railroad through transport vehicle

A technology for tank containers and vehicles, which is applied in the field of the cutting process of the eight-sided arc head of the tank container for railway intermodal transport vehicles, can solve the problems of easy occurrence of waste products, long operation time, low production efficiency, etc., and can ensure the cutting quality. , avoid quality errors, the effect of zero scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] exist Figure 1 to Figure 8 In the schematic diagram of the present invention, the eight-sided arc-shaped head cutting process of the railway intermodal vehicle tank container of the present invention is as follows:

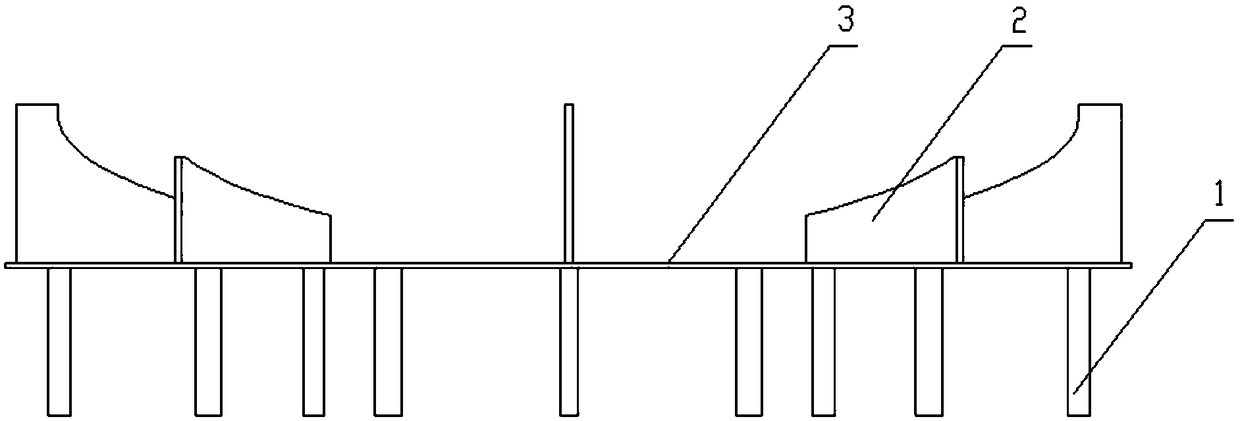

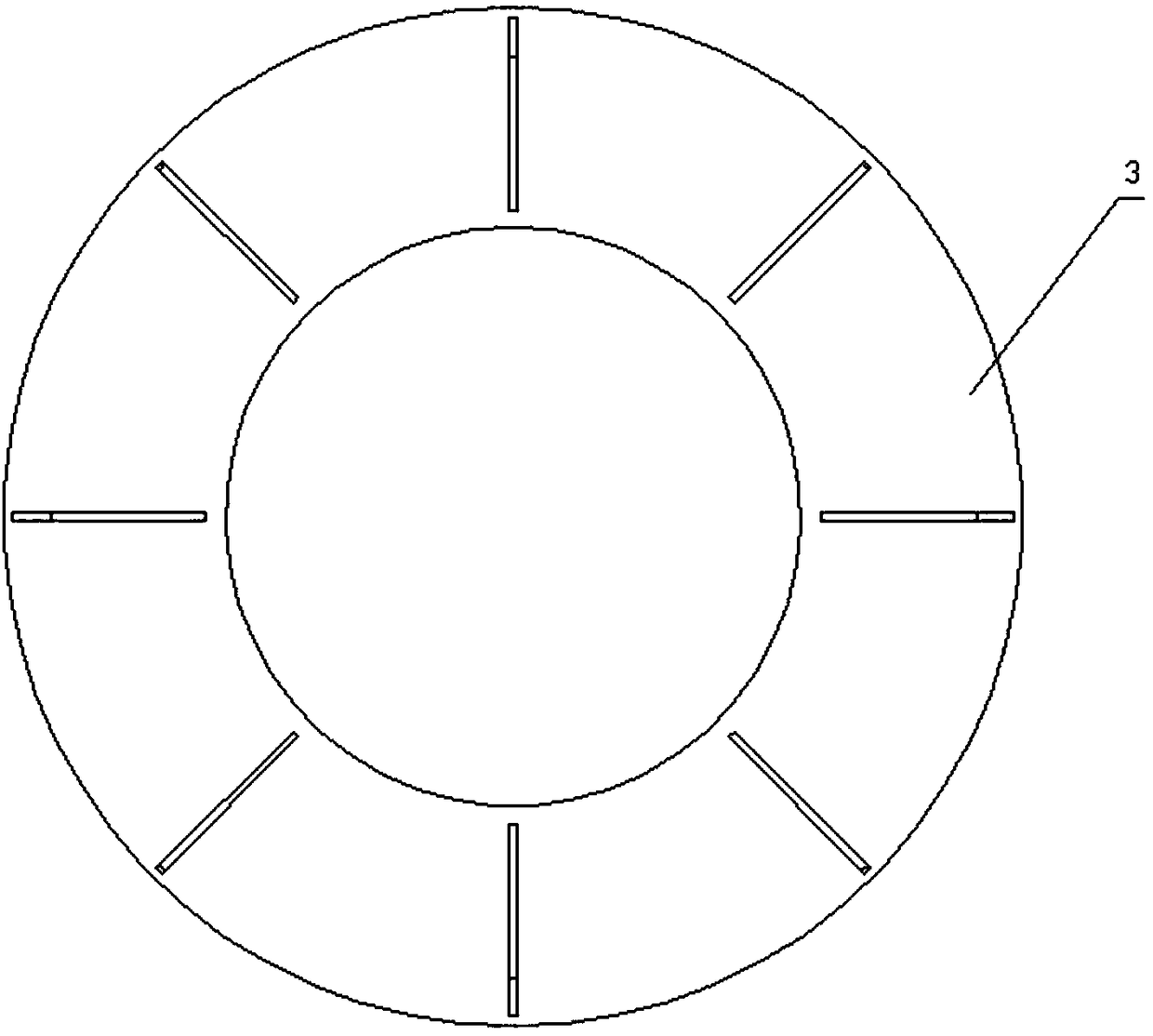

[0026] Step 1. Manufacture the shape-cutting support frame of the head manipulator: the shape-cutting support frame is composed of support frame legs 1 , forming positioning files 2 and support frame panels 3 . The lower part of the support frame panel is provided with support frame legs, the forming positioning block is set on the support frame panel, and the inner surface of the forming positioning block is the same as the arc of the head;

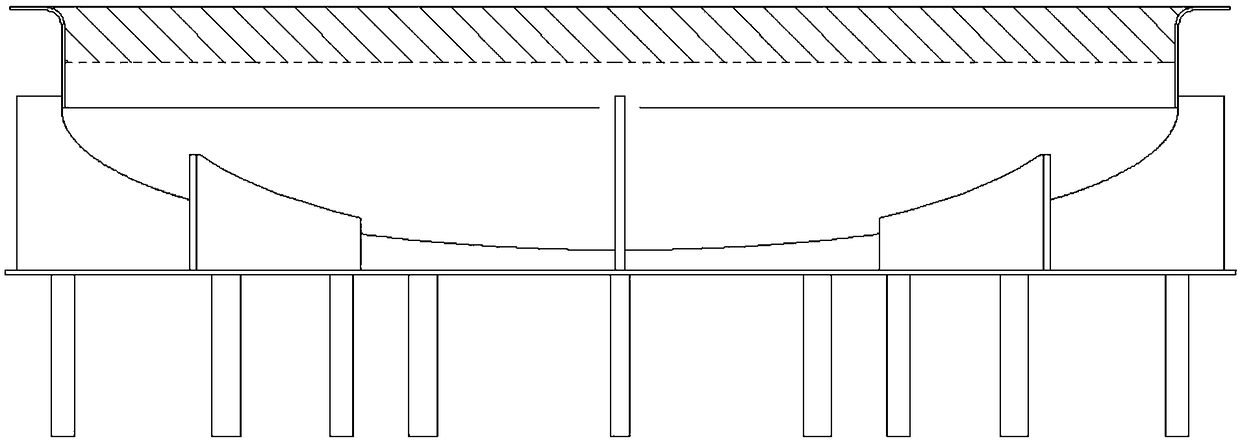

[0027] Step 2. Fit the curved surface of the head and the curved surface of the shape positioning: in order to avoid scratches on the stainless steel, use the crane, use the non-marking pliers, and the head of the elevator, and place it on the cutting support frame steadily and slowly, and inspect the head The arc s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com