Numerical control machining equipment

A technology for processing equipment and seats, which is applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low polishing precision, and poor polishing effect, so as to reduce the labor intensity of workers, Improved work efficiency, low manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

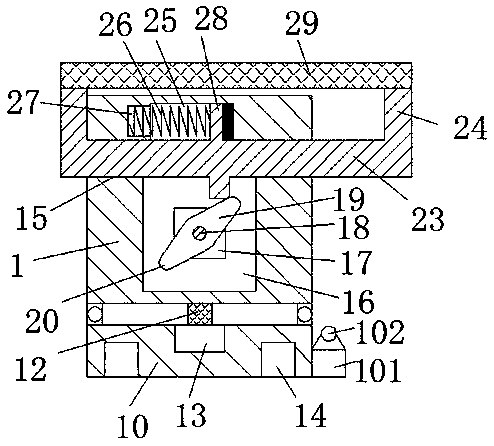

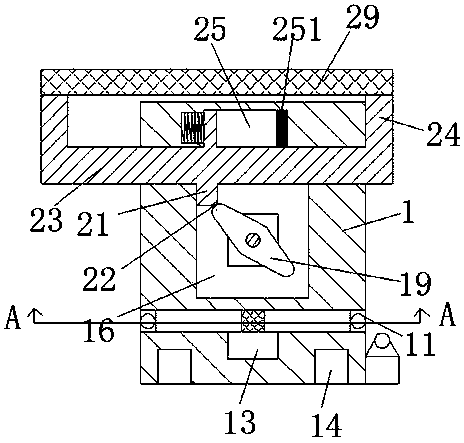

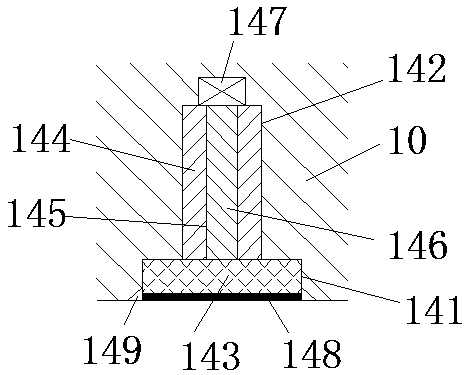

[0019] Such as Figure 1-Figure 4 As shown, a kind of numerical control machining equipment of the present invention includes a base body 10 and a base body 1, the base body 1 is rotatably arranged above the base body 10 through a bearing 11, and the bottom of the base body 10 is surrounded by There is a lifting structure 14, a transmission shaft 12 is fixedly arranged in the middle of the bottom end surface of the base body 1, a first motor 13 connected to the transmission shaft 12 is embedded in the middle of the top end surface of the base body 10, and the top of the base body 1 A sliding groove 15 is provided through the left and right, and a sliding block 23 that can slide left and right is arranged in the sliding groove 15, and a pushing groove 25 is arranged in the top wall of the sliding groove 15, and the sliding groove 15 The bottom end wall is provided with a precursor groove 16, and the top surface of the sliding block 23 is fixedly provided with a push block 28 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com