Self-adaptive motor

A motor, self-adaptive technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of limiting motor power, motor heating, etc., and achieve the effect of reliable connection or disconnection, system stability, and large stable power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

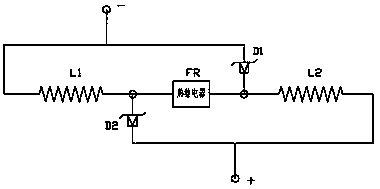

[0016] exist figure 1 In the first embodiment shown, each set of excitation windings includes two identical first windings L1 and second windings L2 connected in series; a thermal relay FR is connected in series between the first winding L1 and the second winding L2 ; A second node is formed between the first winding L1 and the thermal relay FR; a first node is formed between the second winding L2 and the thermal relay FR; the first winding L1 is not connected to the thermal relay One end of the FR connection is connected to the negative terminal of the power module (not shown), and the first node is also connected to the negative terminal of the power module after passing through the first Zener diode module D1; the second winding L2 The end not connected to the thermal relay FR is connected to the positive terminal of the power module, and the second node is also connected to the positive terminal of the power module after passing through the second Zener diode module D2.

...

Embodiment 2

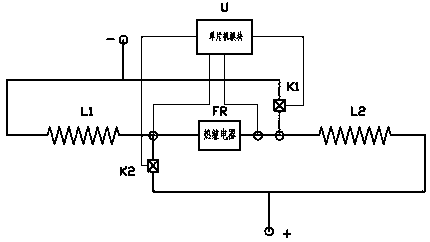

[0020] exist figure 2 In the second embodiment shown, each set of excitation windings includes two identical first windings L1 and second windings L2 connected in series; a thermal relay FR is connected in series between the first winding L1 and the second winding L2 ; A second node is formed between the first winding L1 and the thermal relay FR; a first node is formed between the second winding L2 and the thermal relay FR; the first winding L1 is not connected to the thermal relay FR One end of the connection is connected to the negative terminal of the power module (not shown), and the first node is also connected to the negative terminal of the power module after passing through the first electronic switch K1; the second winding L2 is not connected to the thermal One end of the relay FR connection is connected to the positive end of the power module, and the second node is also connected to the positive end of the power module after passing through the second electronic sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com