Pushing-up-needle type snow ice machine and snow form regulation method thereof

A thimble-type, snow and ice machine technology, applied in the field of machinery, can solve the problems of beverage solution waste, liquid external pollution, cleaning troubles, etc., to avoid waste and pollution, ensure accuracy, and good ice and snow shape effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

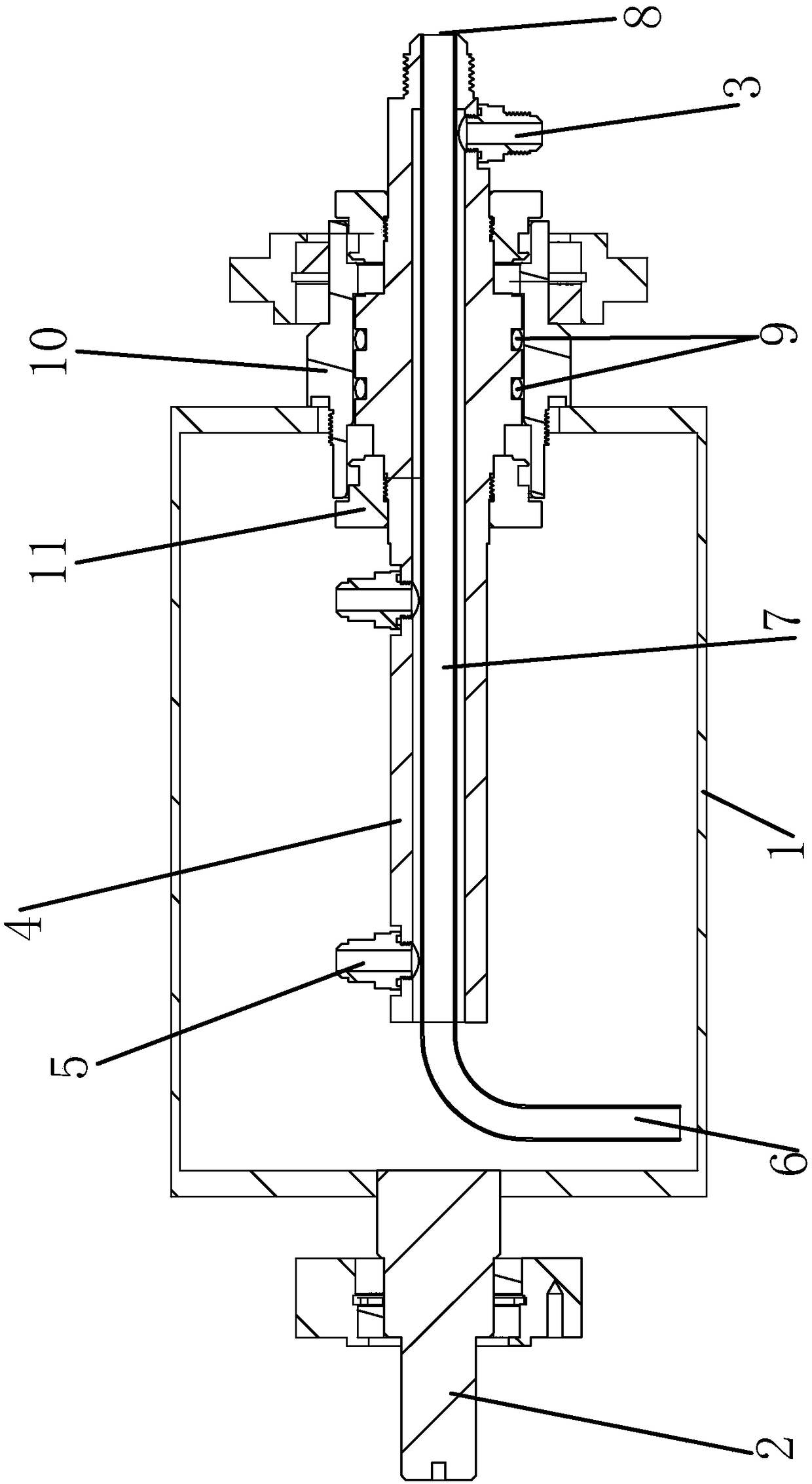

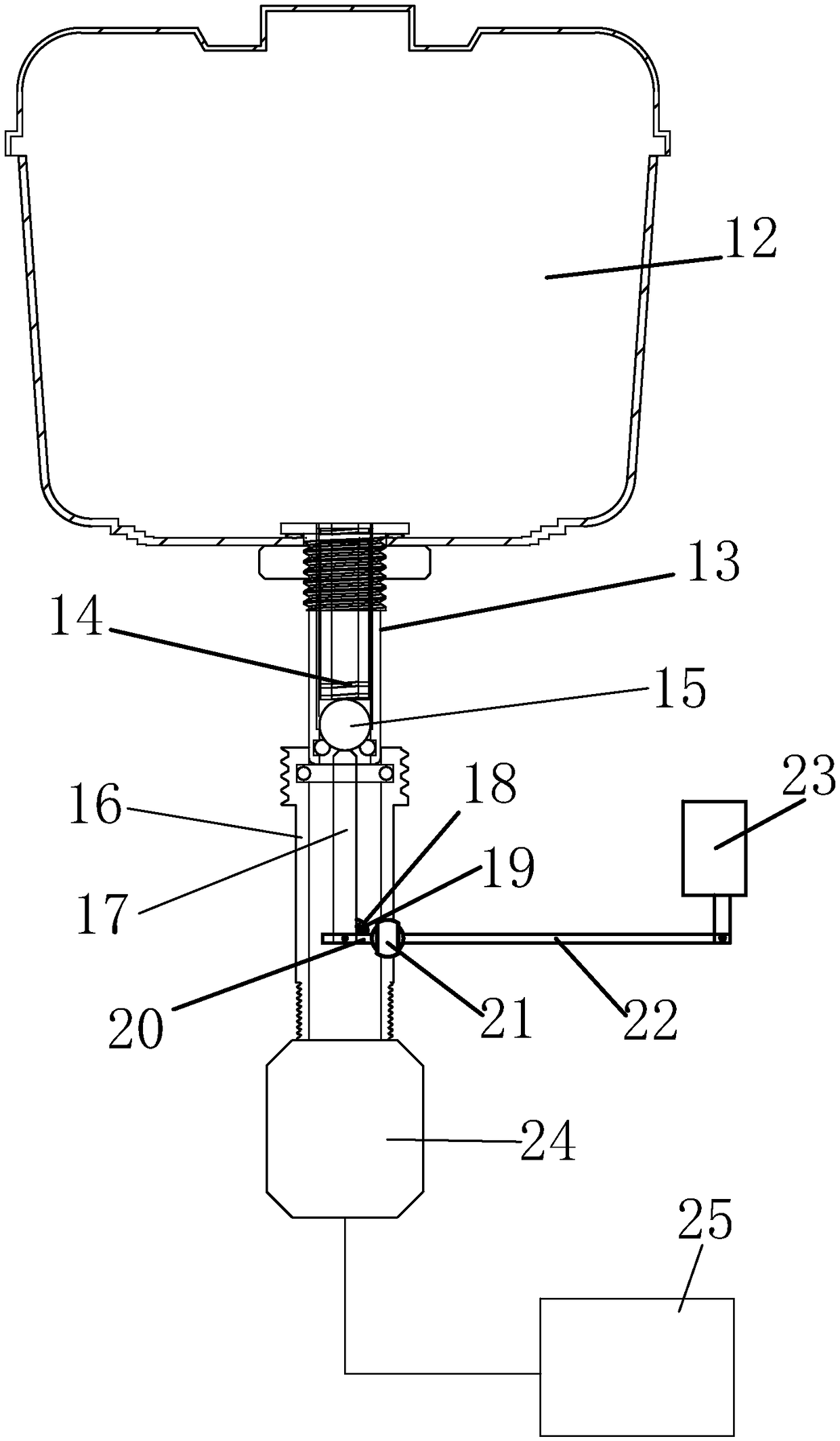

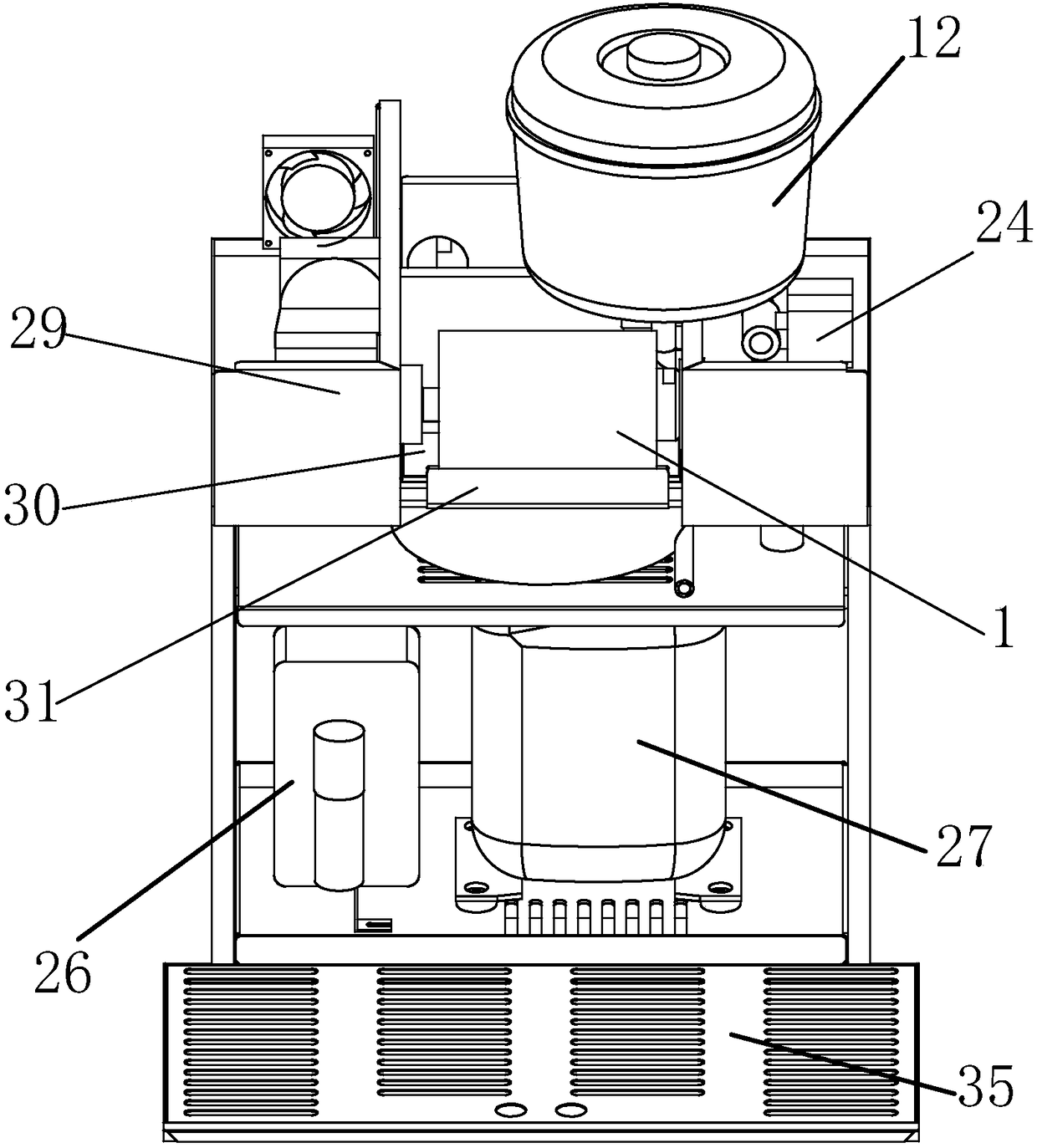

[0043] Such as Figure 1 to Figure 5 As shown, the thimble type snow and ice machine includes a fuselage, the fuselage has an equipment room 34 and an ice making room 32, the equipment room 34 is located under the ice making room 32, and the front of the equipment room 34 and the bottom of the ice making room 32 The tray 35 is placed, and the distribution box 26, the compressor 27 and the double-layer cooling plate 28 are placed in the equipment room 34. The double-layer cooling plate 28 has a water inlet and a water outlet, and electromagnetic valves are arranged on the water inlet and the water outlet. 32, a drum evaporator 1 is placed inside, and one end of the drum evaporator 1 has a rotating shaft 2, and the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com