Automatic thermal solution preparation device and method

An automatic feeding device and hot distribution technology, applied in the direction of mixing methods, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problems of drug quality damage, low production efficiency, deterioration, etc., to eliminate negative effects , Improve production efficiency and the effect of drug quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

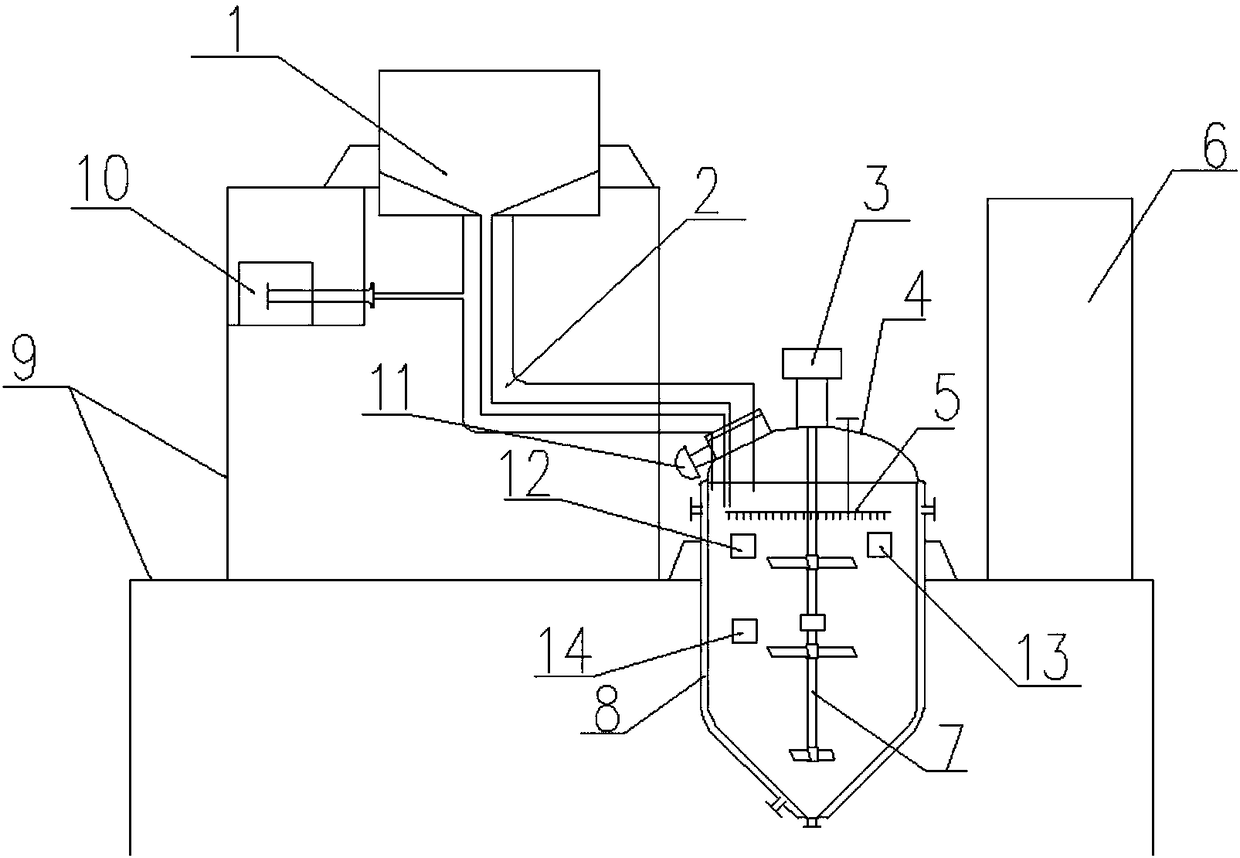

[0030] An automatic hot liquid dispensing device includes tank body 4, jacket 8, steel platform 9, stirring motor 3, stirring paddle 7, automatic feeding device 1, sleeve pipe 2, air compressor 10, anemometer 11, liquid distribution device 5 and controller 6; among them, the steel platform 9 is made of 304 stainless steel to support the whole device; the jacket 8 heats the medium in the tank body 4; the stirring motor 3 provides the driving force for the work of the stirring paddle 7, and the stirring paddle 7 The medium in the tank body 4 is stirred and mixed; the powder in the automatic feeding device 1 is automatically and uniformly fed into the tank body through the sleeve tube 2; the sleeve tube 2 is inserted into the tank body 2 through the feeding port of the tank body 4, for The whole device provides a material channel; the air compressor 10 provides a slight positive pressure for the feeding port to ensure the isolation of the secondary steam; the anemometer 11 detects...

Embodiment 2

[0032] On the basis of Embodiment 1, the automatic hot liquid dispensing device also includes a temperature sensor, a pressure sensor, a liquid level sensor, a steam regulator, a liquid distributor, and a circulating pump; wherein, the temperature sensor detects the temperature of the medium in the tank body 4; the steam The regulator regulates the steam in the tank 4, and the pressure sensor detects the steam pressure adjusted by the steam regulator; the liquid distributor disperses the passing liquid; the circulation pump provides the driving force for the material circulation; the pressure sensor detects the pressure after the steam regulator , the liquid level sensor detects the liquid level in the tank body 4; the temperature sensor, pressure sensor, steam regulator, liquid level sensor, steam regulator, liquid distributor and circulation pump are all electrically connected to the controller 6.

Embodiment 3

[0034] A method for automatic heat dispensing, comprising the steps of:

[0035] (1) The open controller is used to control various parts of the automatic hot liquid dispensing device;

[0036] (2) Use a jacket to heat the purified water inside the tank to boiling, and secondary steam appears in the tank;

[0037] (3) Manually add the quantitative target powder into the automatic feeding device at one time. After starting the feeding, the automatic feeding device sends the powder into the inner tube of the sleeve tube connected to the tank through the internal vibrating plate at a uniform speed, and then the powder enters the tank. Carry out hot distribution; among them, while putting powder into the tank, the secondary steam in the tank is condensed and isolated;

[0038] To condense the secondary steam is to spray a small amount of low-temperature purified water into the tank through the nozzle of the liquid distributor, so that the secondary steam rising during the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com