Compressor valve assembler

A technology of compressors and assemblers, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of complex and large working platform structures, difficult replacement and maintenance, etc., and achieve the effects of shortening maintenance time, improving work efficiency and reducing operation risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

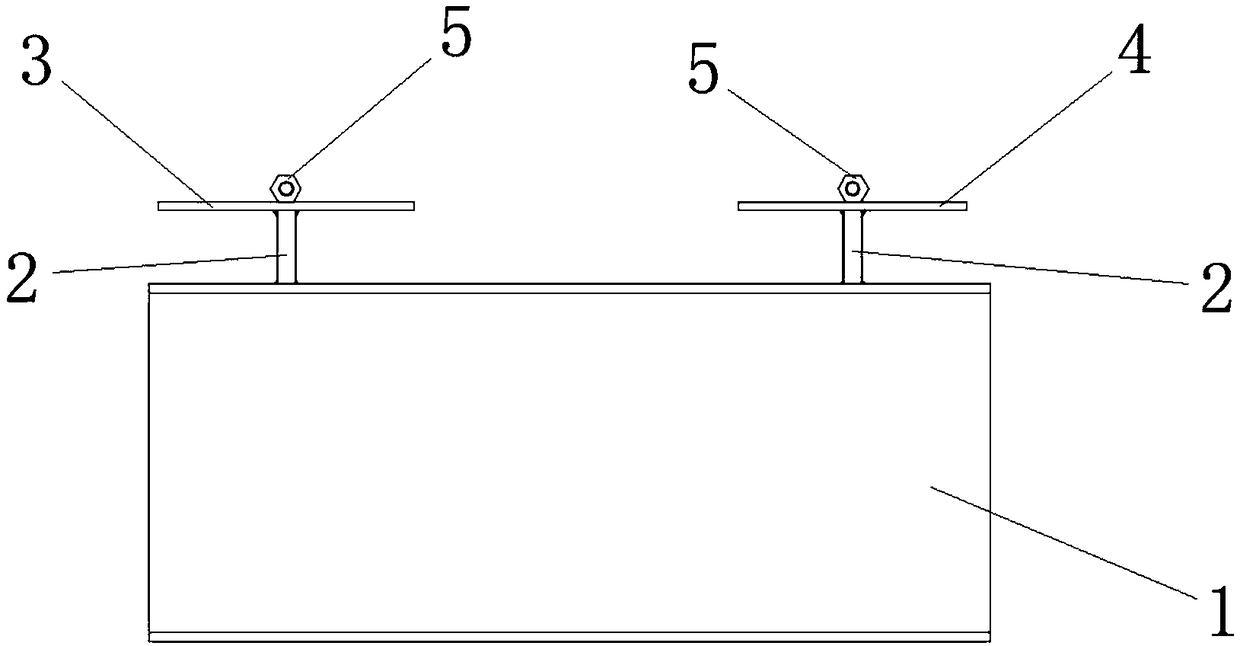

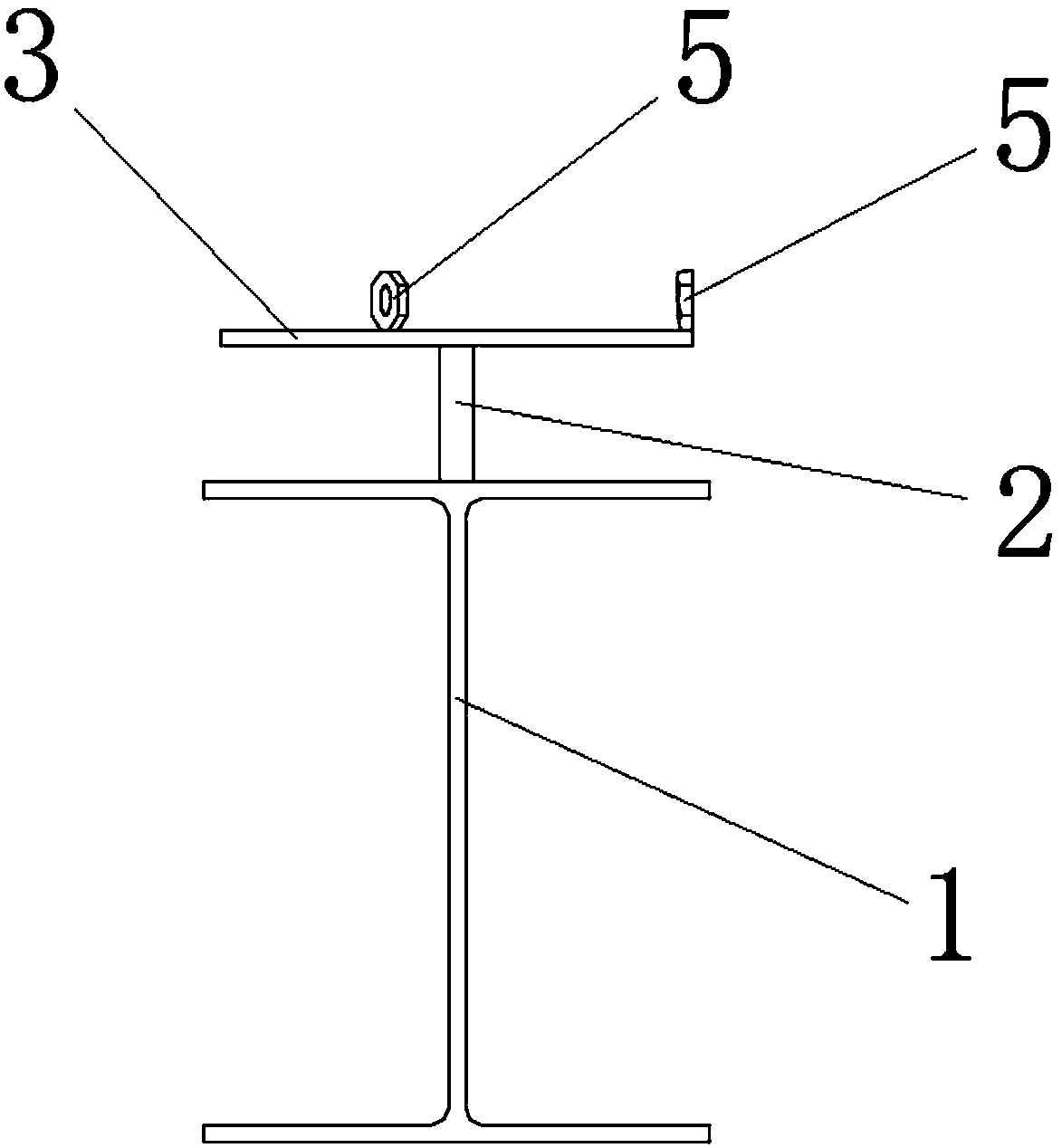

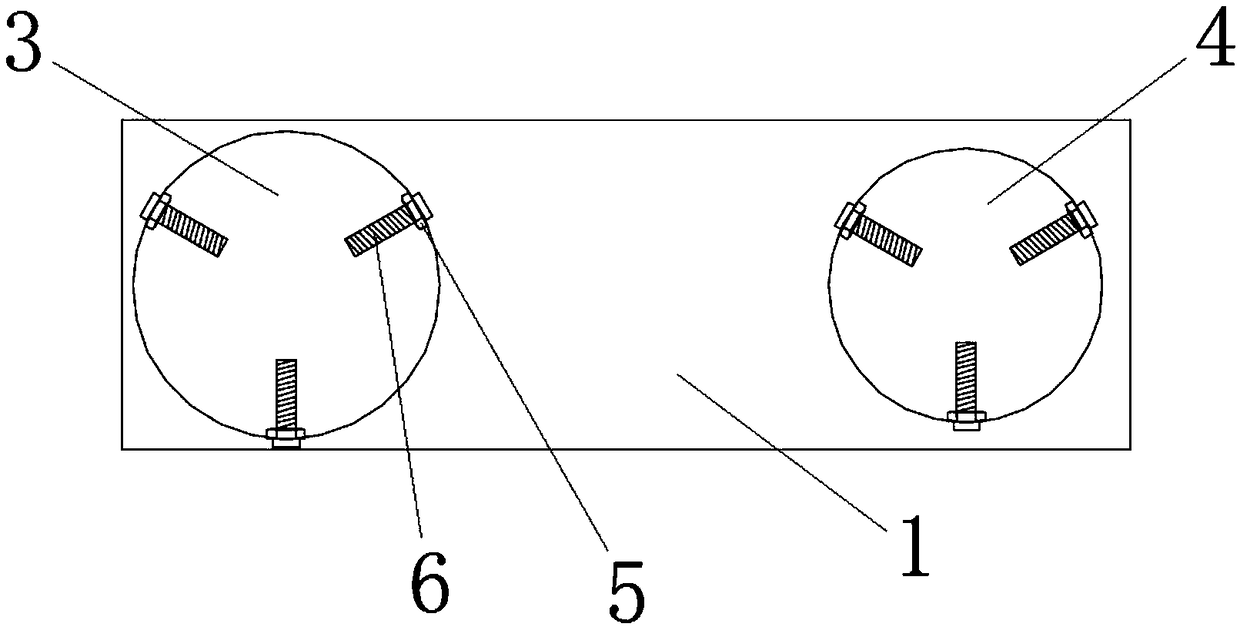

[0023] Compressor valve assembler, such as Figure 1~3 As shown, it includes H steel 1, steel pipe 2, first circular steel plate 3, second circular steel plate 4, nut 5, and bolt 6, wherein the two ends of the upper surface of H steel 1 are respectively welded with a steel pipe 2 and two steel pipes 2 All in a vertical state, the top of one of the steel pipes 2 is welded with a first circular steel plate 3, the top of the other steel pipe 2 is welded with a second circular steel plate 4, the first circular steel plate 3 and the second circular steel plate 4 are both It is horizontal; the upper surface edge of the first circular steel plate 3 is welded with three nuts 5, and the three nuts 5 are evenly distributed along the upper surface edge of the first circular steel plate 3, and the axes of the three nuts 5 intersect at One point, this point is located on the axis of the first circular steel plate 3; The upper surface edge of the second circular steel plate 4 is welded with...

Embodiment 2

[0026] Compressor valve assembler, such as Figure 1~3 As shown, it includes H steel 1, steel pipe 2, first circular steel plate 3, second circular steel plate 4, nut 5, and bolt 6, wherein the two ends of the upper surface of H steel 1 are respectively welded with a steel pipe 2 and two steel pipes 2 All in a vertical state, the top of one of the steel pipes 2 is welded with a first circular steel plate 3, the top of the other steel pipe 2 is welded with a second circular steel plate 4, the first circular steel plate 3 and the second circular steel plate 4 are both It is horizontal; the upper surface edge of the first circular steel plate 3 is welded with three nuts 5, and the three nuts 5 are evenly distributed along the upper surface edge of the first circular steel plate 3, and the axes of the three nuts 5 intersect at One point, this point is located on the axis of the first circular steel plate 3; The edges of the upper surface are evenly distributed, and the axes of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com