A Distributed Drive City Bus Multi-motor Fault Control Method

An urban bus, fault control technology, applied in the direction of control drive, electric vehicle, control device, etc., can solve the problem of unreasonable control strategy, and achieve the effect of reducing the number of fault combinations, preventing further damage, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

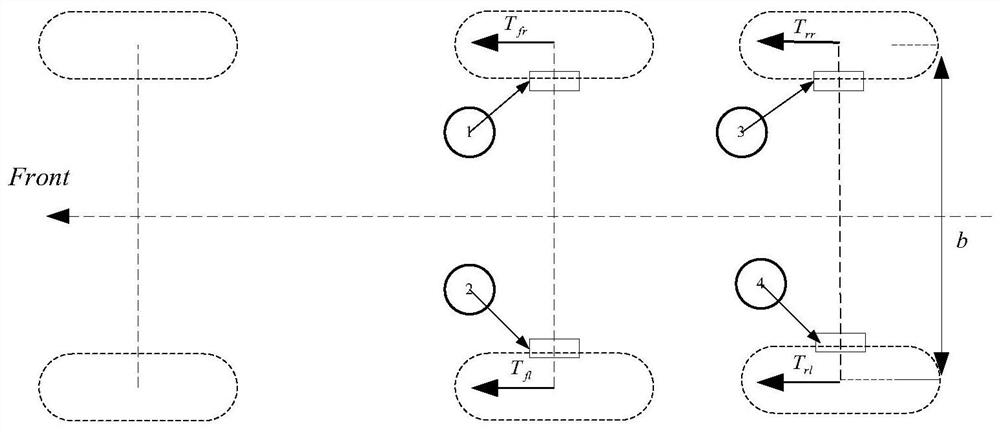

[0023] Such as figure 1 As shown, the distributed vehicle has two drive shafts, corresponding to four drive motors independently driving four wheels on the two drive shafts to travel. Among them, the driving torque of No. 1 driving motor is T fr , the driving torque of No. 2 driving motor is T fl , the driving torque of No. 3 driving motor is T rr , the drive torque of drive motor No. 4 is T rl .

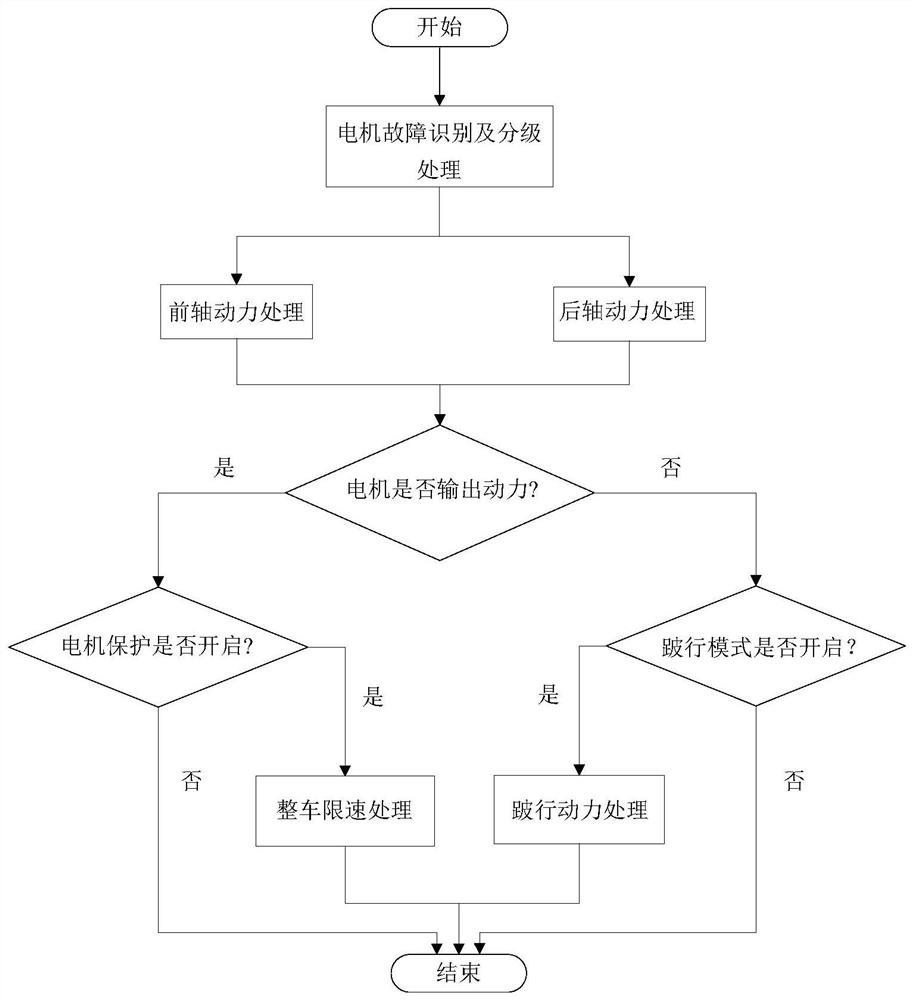

[0024] figure 2 The logic diagram of the multi-motor fault control method for distributed drive urban buses is given, including:

[0025] In the first step, the whole vehicle performs fault detection on the motor and motor controller, and judges whether it is a serious fault according to the detection results.

[0026] In the second step, if it is a serious fault, stop the power output of the corresponding motor; if it is a non-serious faul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com