A high-durability lightweight anti-typhoon electric pole and its manufacturing method

A durable and anti-typhoon technology, applied in the direction of manufacturing tools, ceramic molding machines, towers, etc., can solve the problems of heavy concrete poles, unreasonable safety, and excessive lower section, so as to improve the comprehensive wind resistance and increase the application level , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

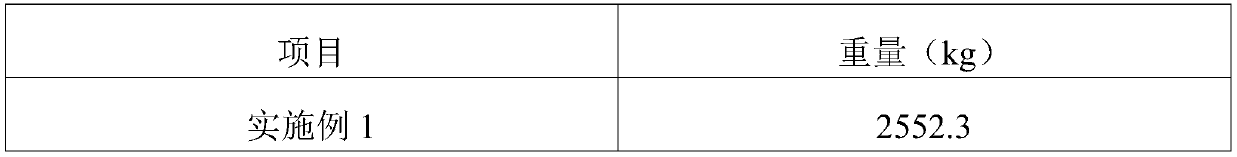

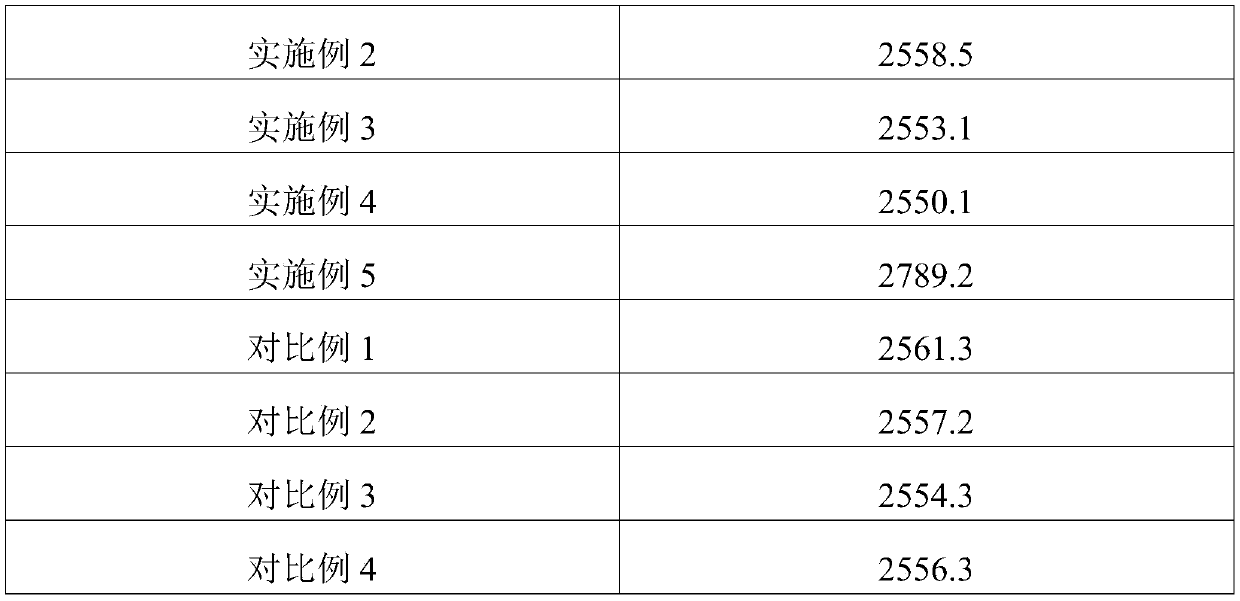

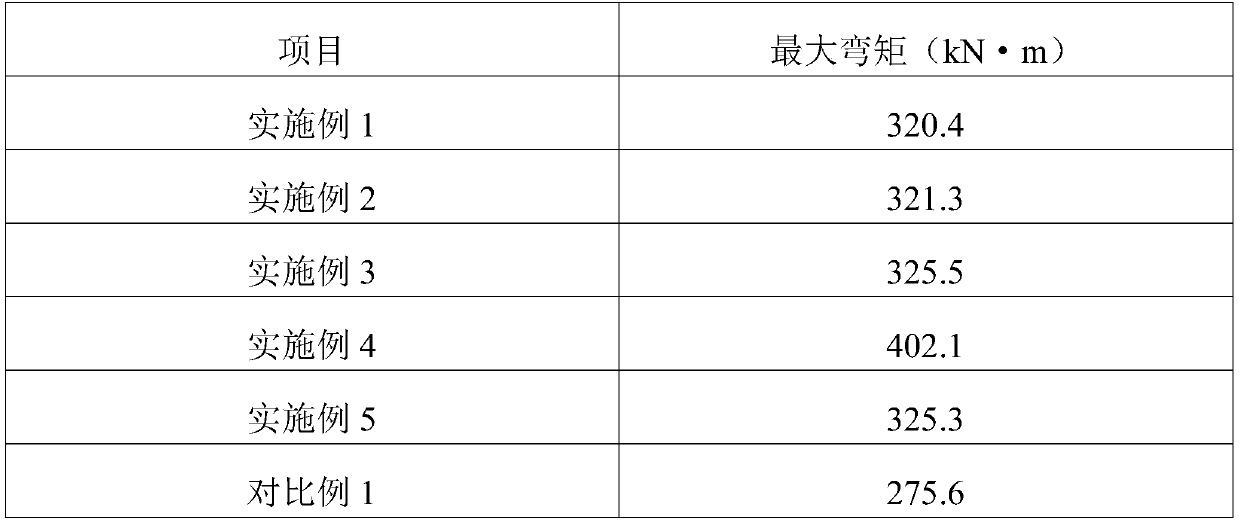

Embodiment 1

[0024] A high-durability lightweight anti-typhoon electric pole is made of concrete and steel bars. The concrete adopts 200Mpa grade active powder concrete, including the following raw materials in parts by weight: 700 parts of cement, 23.8 parts of glutinous rice flour, 200 parts of silica fume, coarse 728.7 parts of sand, 364.2 parts of medium sand, 182.2 parts of fine sand, 21 parts of shell powder, 24 parts of chitin, 150.9 parts of steel fiber, 5.1 parts of basalt fiber, 60.1 parts of water reducing agent, and 140 parts of water.

Embodiment 2

[0026] A high-durability lightweight anti-typhoon electric pole is made of concrete and steel bars. The concrete is 200Mpa grade active powder concrete, including the following raw materials in parts by weight: 800 parts of cement, 100 parts of glutinous rice flour, 123.8 parts of silica fume, coarse 572.8 parts of sand, 286.6 parts of medium sand, 143.2 parts of fine sand, 100 parts of shell powder, 80 parts of chitin, 129 parts of steel fiber, 27 parts of basalt fiber, 77.6 parts of water reducing agent, and 160 parts of water.

Embodiment 3

[0028] A high-durability lightweight anti-typhoon electric pole is made of concrete and steel bars. The concrete is 200Mpa grade active powder concrete, including the following raw materials in parts by weight: 746 parts of cement, 40 parts of glutinous rice flour, 183.8 parts of silica fume, coarse 683.2 parts of sand, 342.2 parts of medium sand, 170.8 parts of fine sand, 34 parts of shell powder, 30 parts of chitin, 148 parts of steel fiber, 8 parts of basalt fiber, 66.9 parts of water reducing agent, and 147.1 parts of water.

[0029] Above-mentioned embodiment 1~3 is to make the electric pole that tip diameter is 230 millimeters, long 21 meters as example, and electric pole is divided into upper section and lower section, and upper section is 8 meters long, and configuration 6 is 1884mm in cross-sectional area. 2 The non-prestressed steel bars are uniformly distributed in a regular hexagonal shape along the circumference of the pole, the lower section is 13 meters long, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com