A kind of interior and exterior wall putty powder with high water resistance and its preparation method and application

A technology of interior and exterior walls and putty powder, which is applied in the direction of filling slurry, etc., can solve the problems of affecting market promotion, putty powder is not environmentally friendly, and poor water resistance, and achieves excellent environmental protection performance, long storage time, and reduced complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

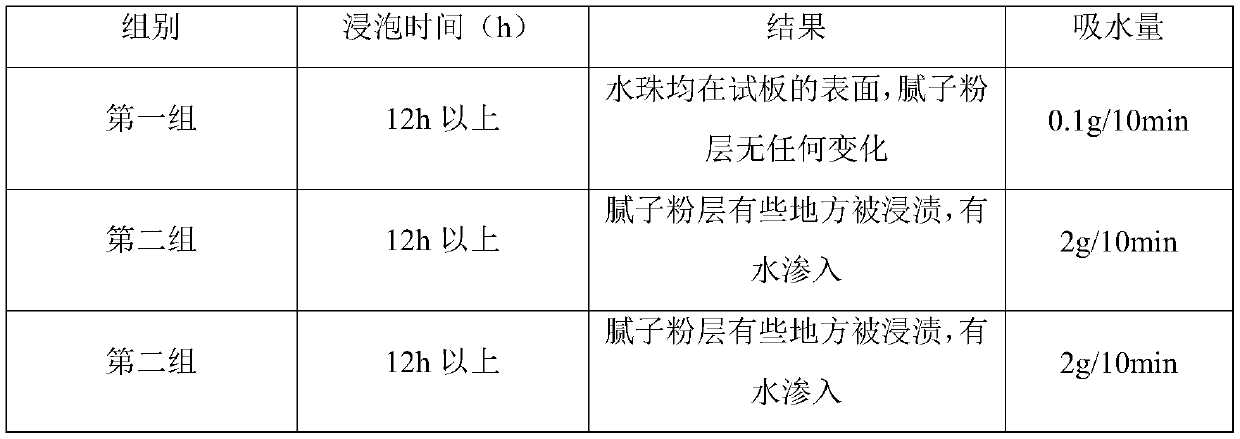

[0042] The concrete formula of this interior and exterior wall putty powder carries out batching according to following table 1:

[0043] Table 1 specific formula

[0044] Component (kg) Example 1 Example 2 Example 3 Example 4 Example 5 Sulphoaluminate cement 750 800 770 780 775 black cement 20 10 18 12 16 80 mesh quartz sand 100 200 120 180 160 calcium chloride 14 12 14 13 13 lithium chloride 8 7 7.5 7 7 talcum powder 7 4 6 5 5 Zinc stearate 4 8 5 7 6 Hydroxypropylmethylcellulose 7 4 5 6 6 UNF-4 early strength superplasticizer 4 8 7 5 6 wollastonite powder 5 3 4 5 4.5 Titanium dioxide 1 2 1.2 1.5 1.3 Hexametaphosphate 5 12 10 7 8 heavy calcium powder 70 80 72 78 75 double fly powder 40 50 48 42 46 rubber powder 2 3 2.2 2.8 2.5 Ash calcium powder 10 5 8 6 7

[0045] The preparation method comprises...

Embodiment 6-8

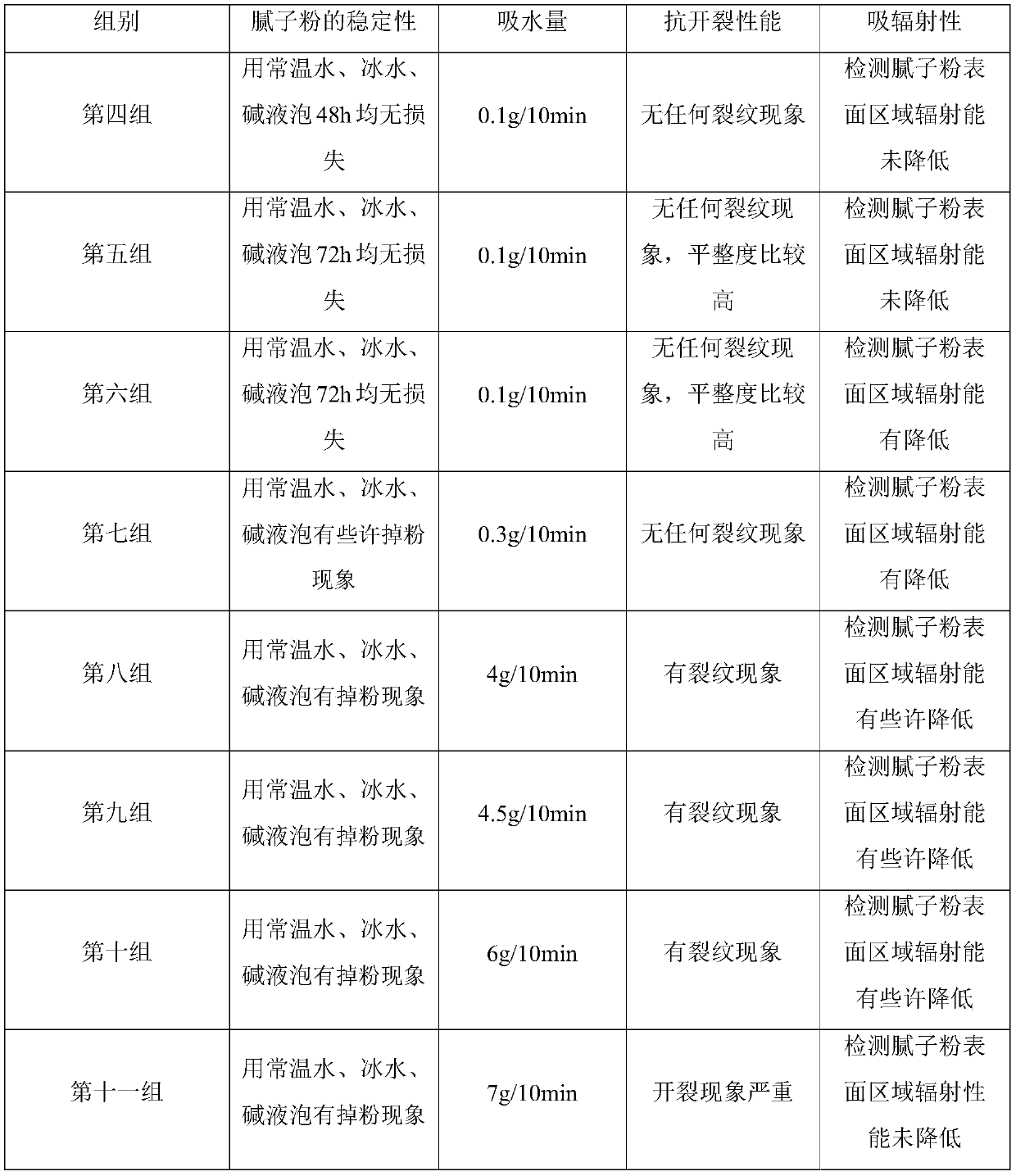

[0049] The concrete formula of this interior and exterior wall putty powder carries out batching according to following table 2:

[0050] Table 2 specific formula

[0051] Component (kg) Example 6 Example 7 Example 8 Sulphoaluminate cement 770 790 770 black cement 15 12 18 80 mesh quartz sand 120 180 170 calcium chloride 13 12 14 lithium chloride 8 7 7.5 talcum powder 7 4 6 Zinc stearate 4 8 5 Hydroxypropylmethylcellulose 7 4 5 FD-N-S early strength superplasticizer 4 8 7 wollastonite powder 5 3 4 Titanium dioxide 1 2 1.2 Hexametaphosphate 5 12 10 heavy calcium powder 70 80 75 double fly powder 40 50 48 rubber powder 2 3 2.2 Ash calcium powder 10 5 8 Diatom mud 5 7 0 Magnetic filler (soft magnetic powder) 0 5 8

[0052] The preparation method comprises the following steps:

[0053] 1) First mix sulfoaluminate cement,...

Embodiment 9

[0056] Concrete formula is consistent with embodiment 8, just preparation method carries out according to the following steps:

[0057] 1) First mix sulfoaluminate cement, 80 mesh quartz sand, talcum powder, zinc stearate, wollastonite powder, titanium dioxide, black cement, heavy calcium powder, double fly powder, rubber powder, lime calcium powder, diatom mud , Add the magnetic filler into the stirring tank, control the stirring rate at 500rpm while stirring, and stir for 12h;

[0058] 2) Add calcium chloride, lithium chloride, hydroxypropyl methylcellulose, water reducer, and sodium hexametaphosphate to the mixing tank in sequence, and control the stirring rate at 400rpm while stirring, and mix and stir for 10-20min. Pack it into a finished product of 10kg / bag, and store it in a dry place at normal temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com