Dredging device and crane with dredging device

A dredging device and sliding column technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of high labor intensity for workers, low efficiency of sludge treatment, dredging and grabbing Low efficiency and other problems, to achieve a wide range of dredging, easy to manufacture and install on a large scale, to ensure the effect of stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

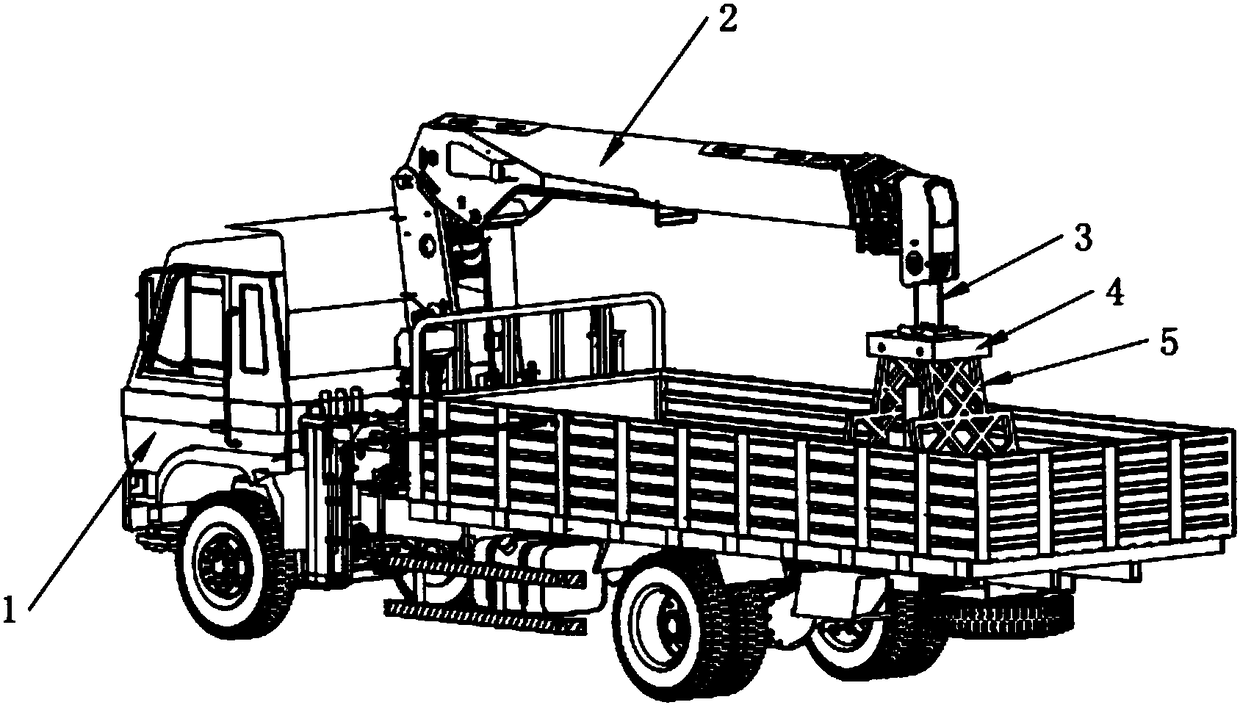

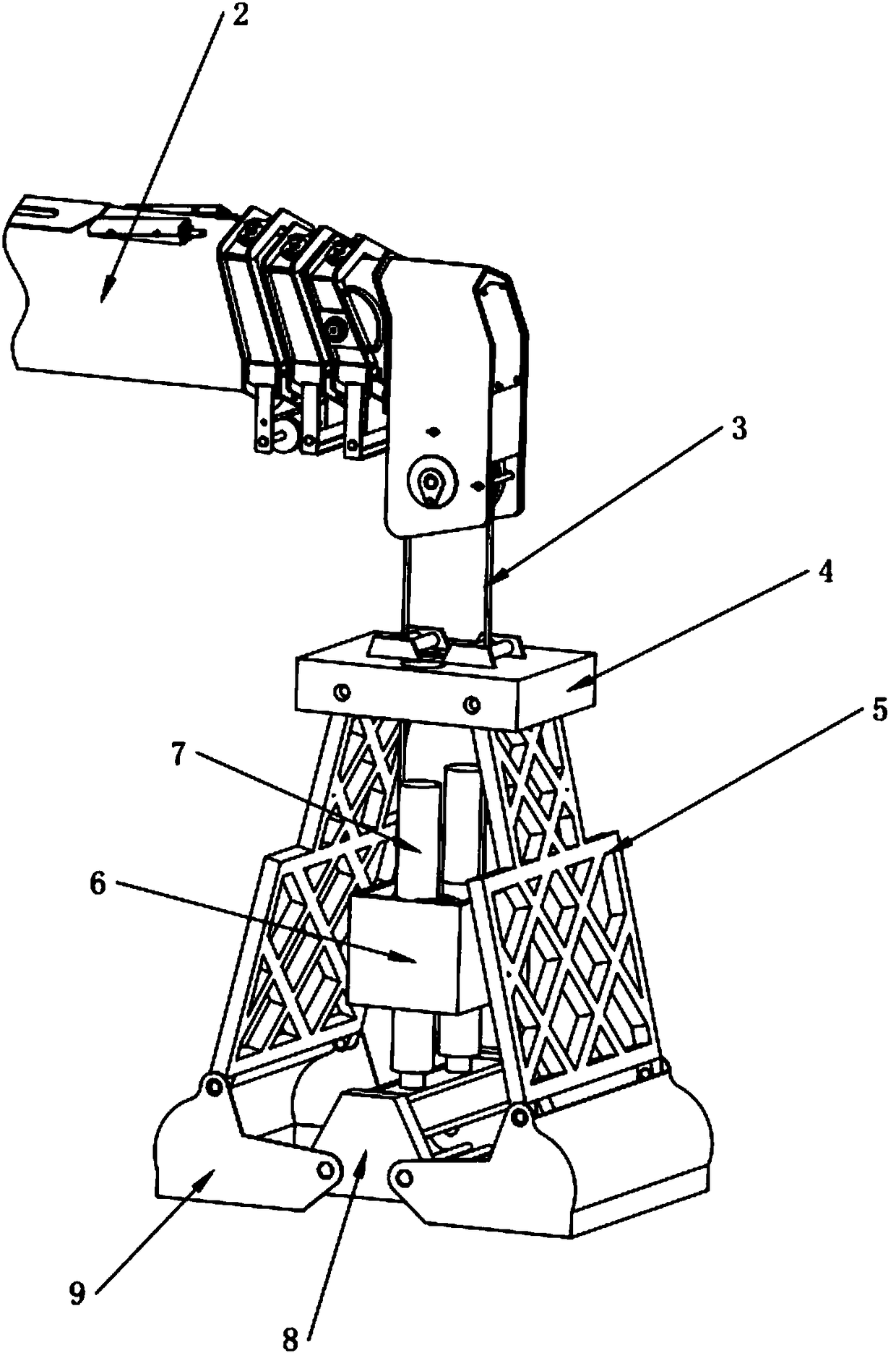

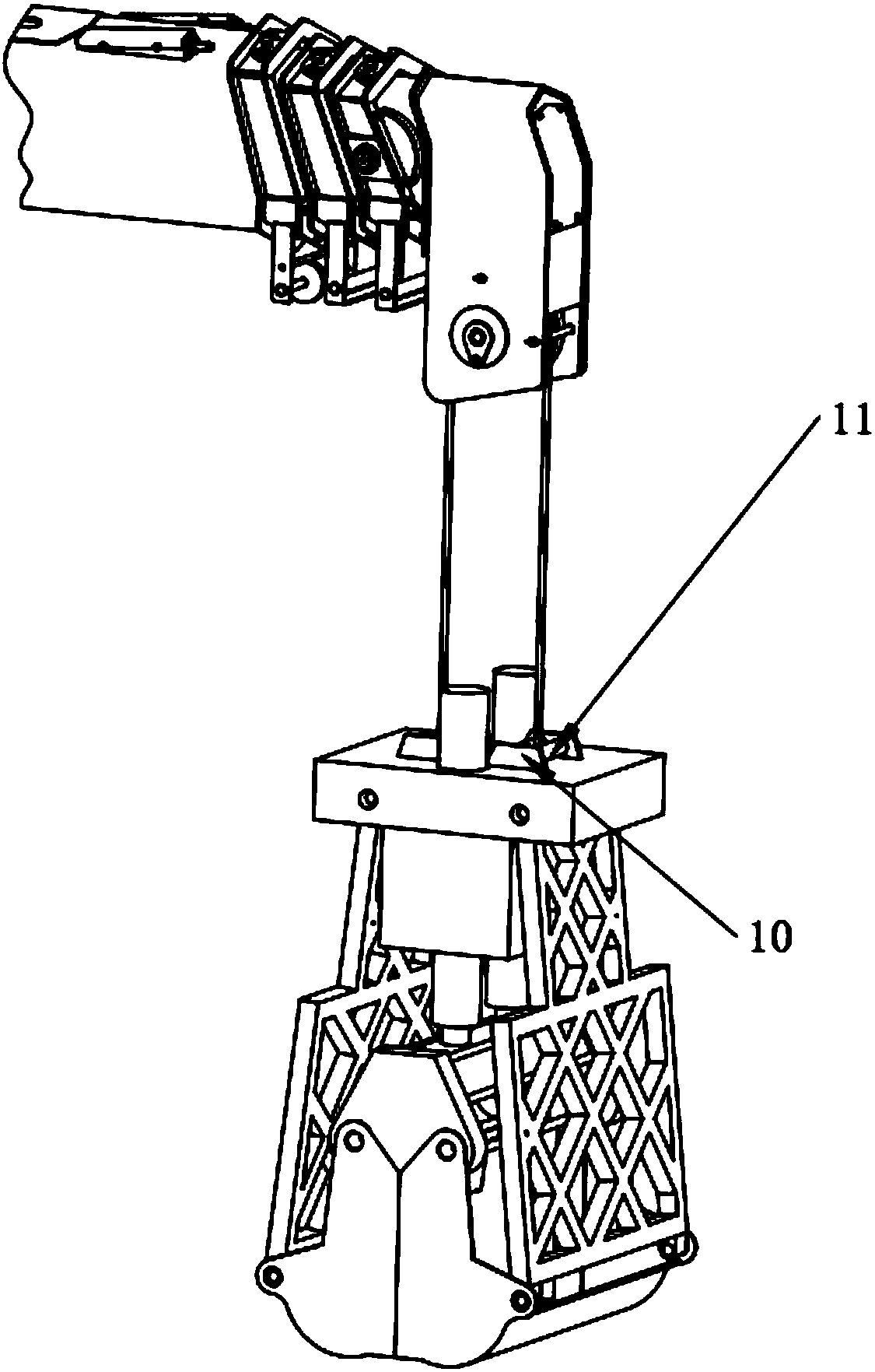

[0024] Such as figure 1 and figure 2 As shown, a dredging device and a crane with a dredging device include a car body 1 and a hoist 2, an upper frame body 4, a lower frame body 8, a petal-shaped hopper 9, a sliding frame 6, a truss connecting rod 5, and a sliding column 7 The winch 2 is installed on the chassis of the car body 1, the truss connecting rod 5 is provided with two and one of the common ends is respectively hinged on the upper frame body 4 in parallel, and the area between the two truss connecting rods 5 is used to form an installation space, The sliding column 7 is slidably arranged on the upper fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com