Coercing stirring pump truck

A technology of forced mixer and pump truck, applied in cement mixing device, vehicle maintenance, clay preparation device, etc., can solve problems such as damage to buildings, reduce construction efficiency of concrete pumping, affect building quality, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

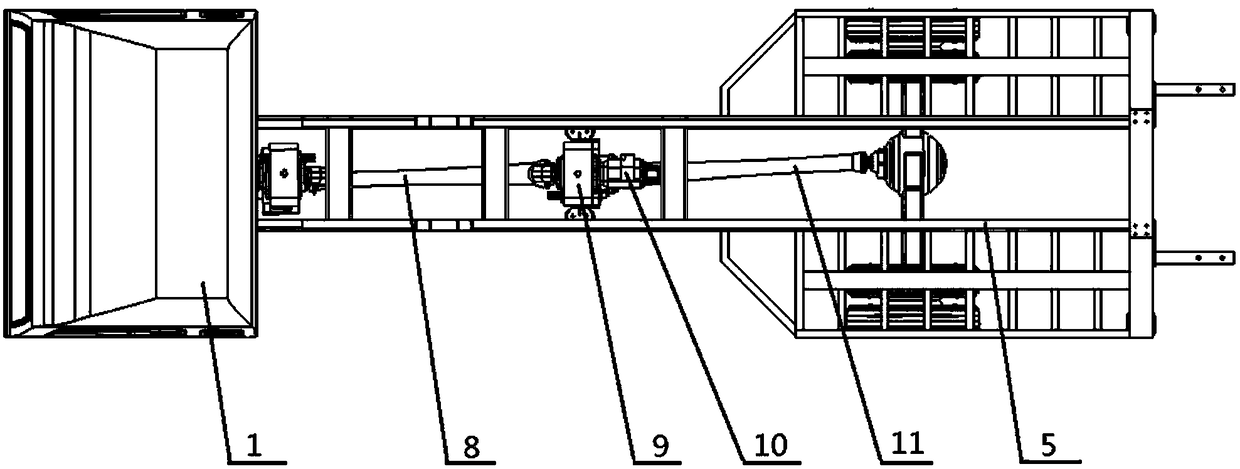

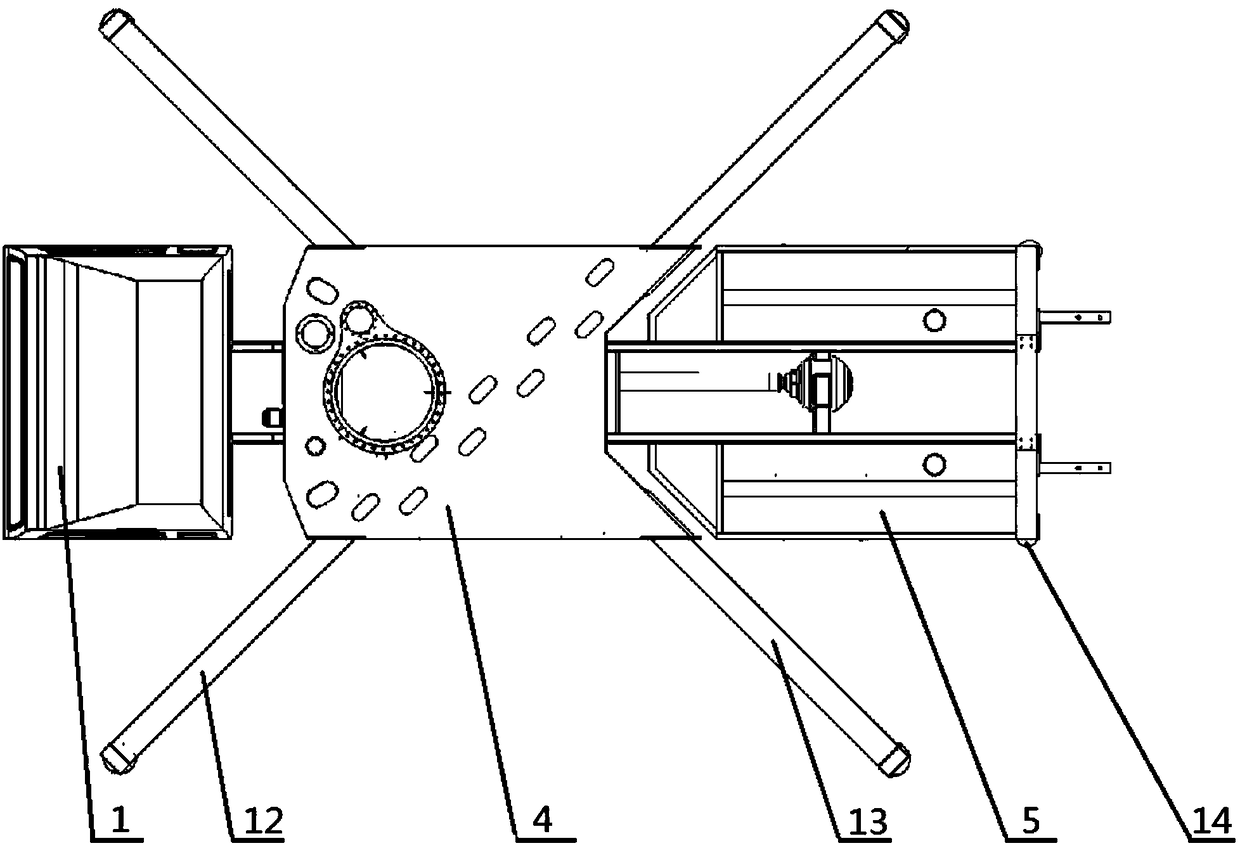

[0024] refer to Figure 1-4 , a forced mixing pump truck is proposed in this embodiment, including a car chassis 1, a pump truck outrigger mechanism 2, a boom distribution mechanism 3, a base structure 4, a subframe 5, a double-shaft forced mixer 6, a pump The delivery mechanism 7, the first connecting shaft 8, the transfer case 9, the hydraulic oil pump 10 and the second connecting shaft 11, the sub-frame 5 are fixedly installed on the automobile chassis 1, and the sub-frame 5 is provided with horizontal rails horizontally, which is convenient for forcing The mixer 6 moves horizontally on the sub-frame 5, and the side of the top of the sub-frame 5 close to the front of the vehicle is connected and fixed with a base structure 4, and the base structure 4 and the horizontal track are arranged at an angle of 90 degrees, and the base structure 4 The boom distributing mechanism 3 is fixedly installed on the top of the boom. The boom distributing mechanism 3 has a multi-section fold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com