On-line sampler

A technology of sampler and sampling rod, applied in the direction of sampling device, etc., can solve the problem of easy blockage of sampler, achieve easy sampling volume, compact layout, and solve the effect of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

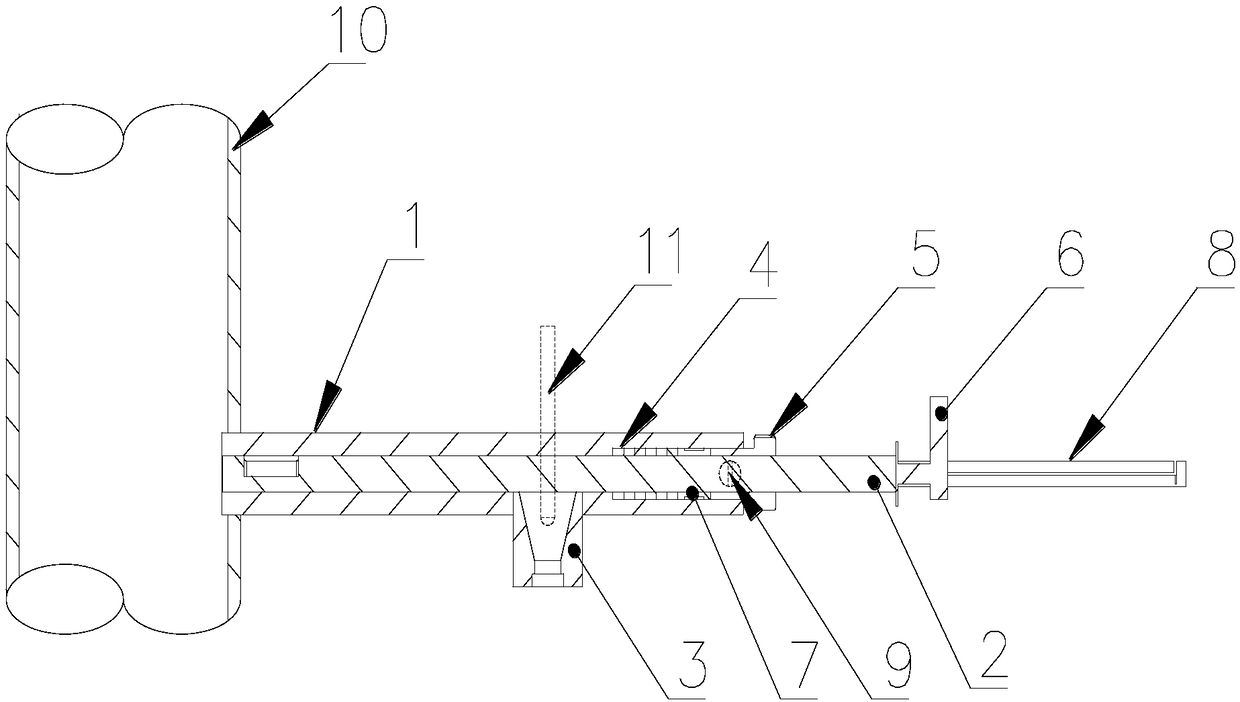

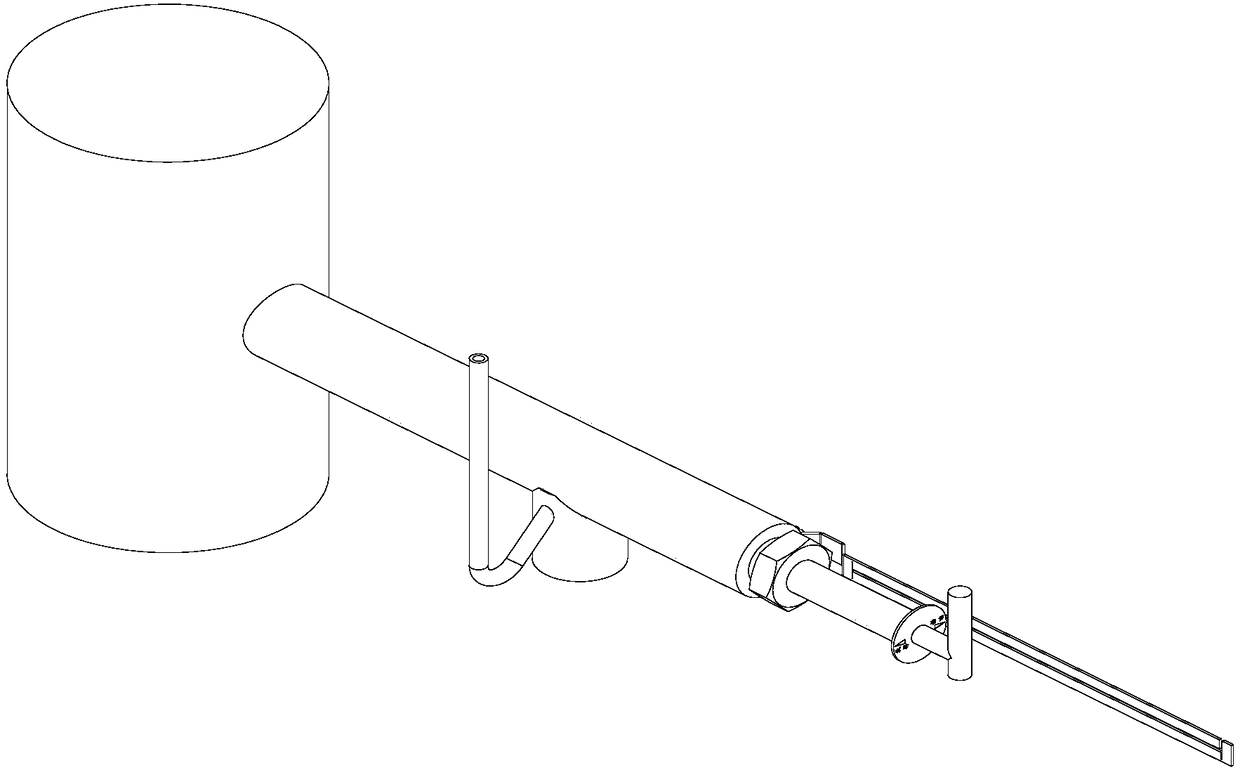

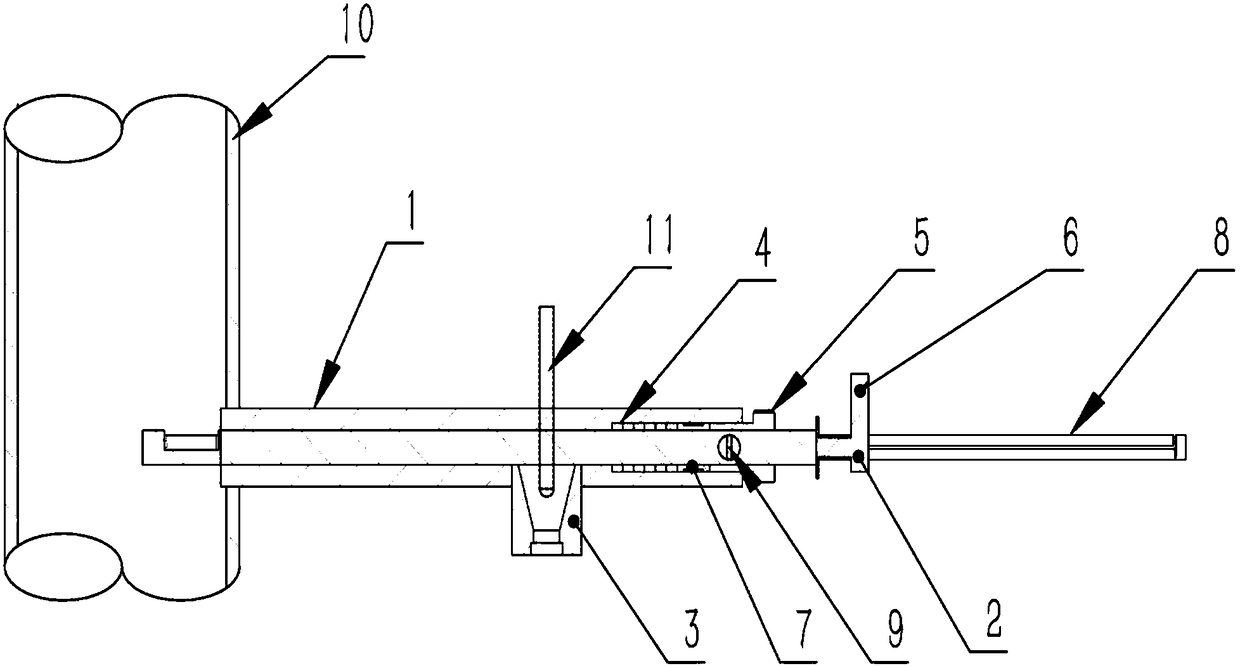

[0029] An online sampler such as figure 1 and 2 As shown, it includes sampler body, movable sampling rod 2, sampling outlet 3, sealing packing 4, sampling operation handle 6, positioning scale 8 and air blowing pipe 11, sampler body 1 is connected with reactor 10, sampler body Connected with the reactor through a flange, the movable sampling rod 2 is arranged inside the sampler body 1, and the movable sampling rod 2 is provided with a sampling groove, the sampling groove is an open groove, and the open groove is used for quantitatively measuring the volume of the sample. The sampling tank is set at the left end of the movable sampling rod 2, and the end of the movable sampling rod 2 away from the reactor extends to the outside of the sampler body 1, and the right side of the sampler body 1 is provided with a sealing gland 5, and the sealing gland 5 surrounds the movable On the outside of the sampling rod 2, the right part of the sealing packing 4 is also provided with a packi...

Embodiment 2

[0032] An online sampler such as Figure 6 As shown, it includes a sampler body 1, a movable sampling rod 2, a sampling outlet 3, a sealing packing 4, a sampling operation handle 6, a positioning scale 8 and an air blowing pipe 11. The sampler body 1 is connected with a reactor 10, and the active sampling The rod 2 is arranged inside the sampler body 1, and the movable sampling rod 2 is provided with a sampling groove, the sampling groove is an open groove, and the open groove is used for quantitatively measuring the volume of the sample, and the sampling groove is arranged at the left end of the movable sampling rod 2 , the end of the movable sampling rod 2 away from the reactor extends to the outside of the sampler body 1, the right side of the sampler body 1 is provided with a sealing gland 5, the sealing gland 5 surrounds the outer side of the movable sampling rod 2, and the sealing packing 4 The right part is also provided with a packing pressure ring 7, and the sampling ...

Embodiment 3

[0036] An online sampler such as Figure 7As shown, it includes a sampler body 1, a movable sampling rod 2, a sampling outlet 3, a sealing packing 4, a sampling operation handle 6, a positioning scale 8 and an air blowing pipe 11. The sampler body 1 is connected with a reactor 10, and the active sampling The rod 2 is arranged inside the sampler body 1, and the movable sampling rod 2 is provided with a sampling groove, the sampling groove is an open groove, and the open groove is used for quantitatively measuring the volume of the sample, and the sampling groove is arranged at the left end of the movable sampling rod 2 , the end of the movable sampling rod 2 away from the reactor extends to the outside of the sampler body 1, the right side of the sampler body 1 is provided with a sealing gland 5, the sealing gland 5 surrounds the outer side of the movable sampling rod 2, and the sealing packing 4 The right part is also provided with a packing pressure ring 7, and the sampling d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com