Device for testing on thermal simulation test machine

A test device and thermal simulation technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of inconsistent deformation temperature, large sample size, uneven temperature distribution, etc. Tendency to deformation, avoid uneven temperature distribution, easy assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

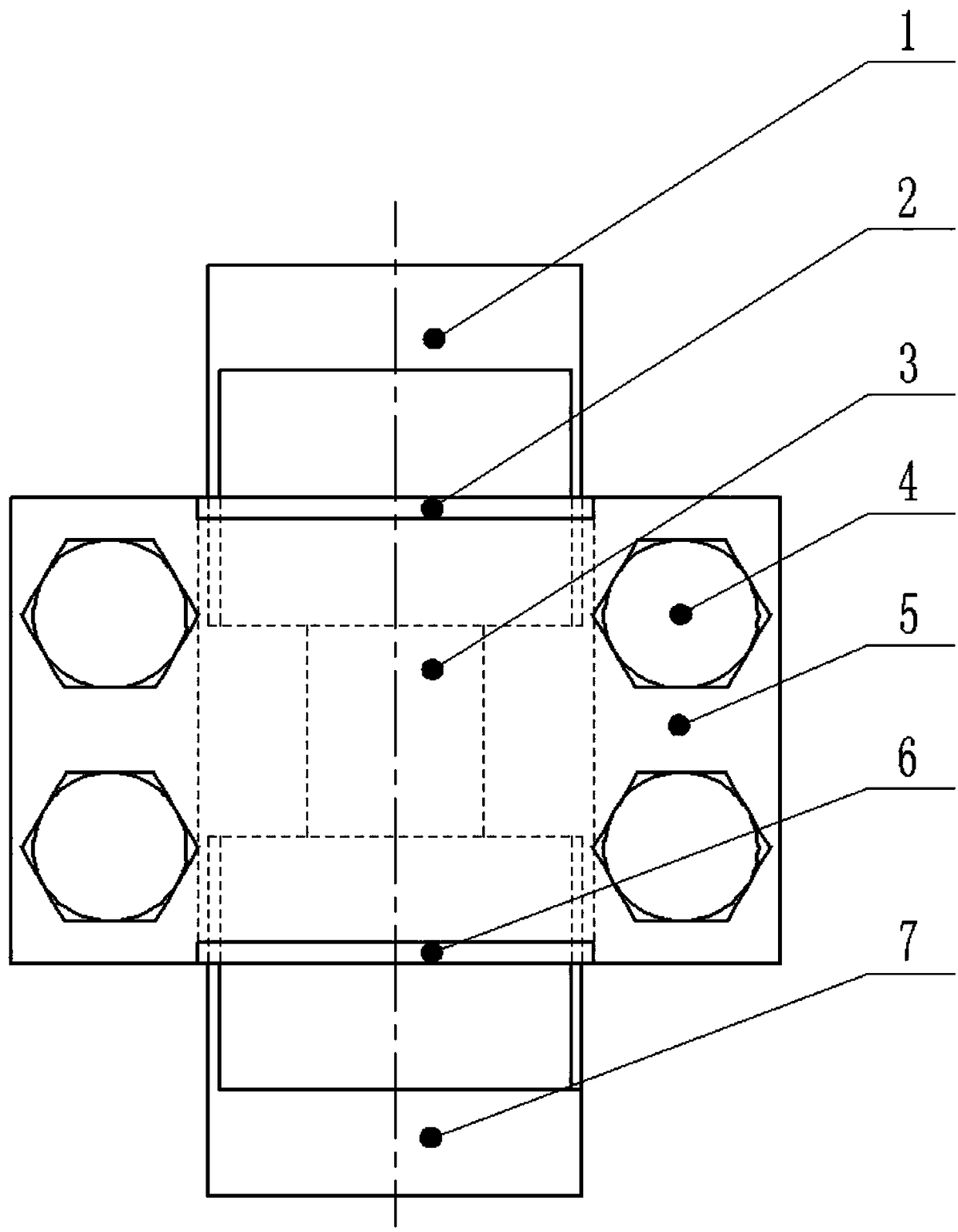

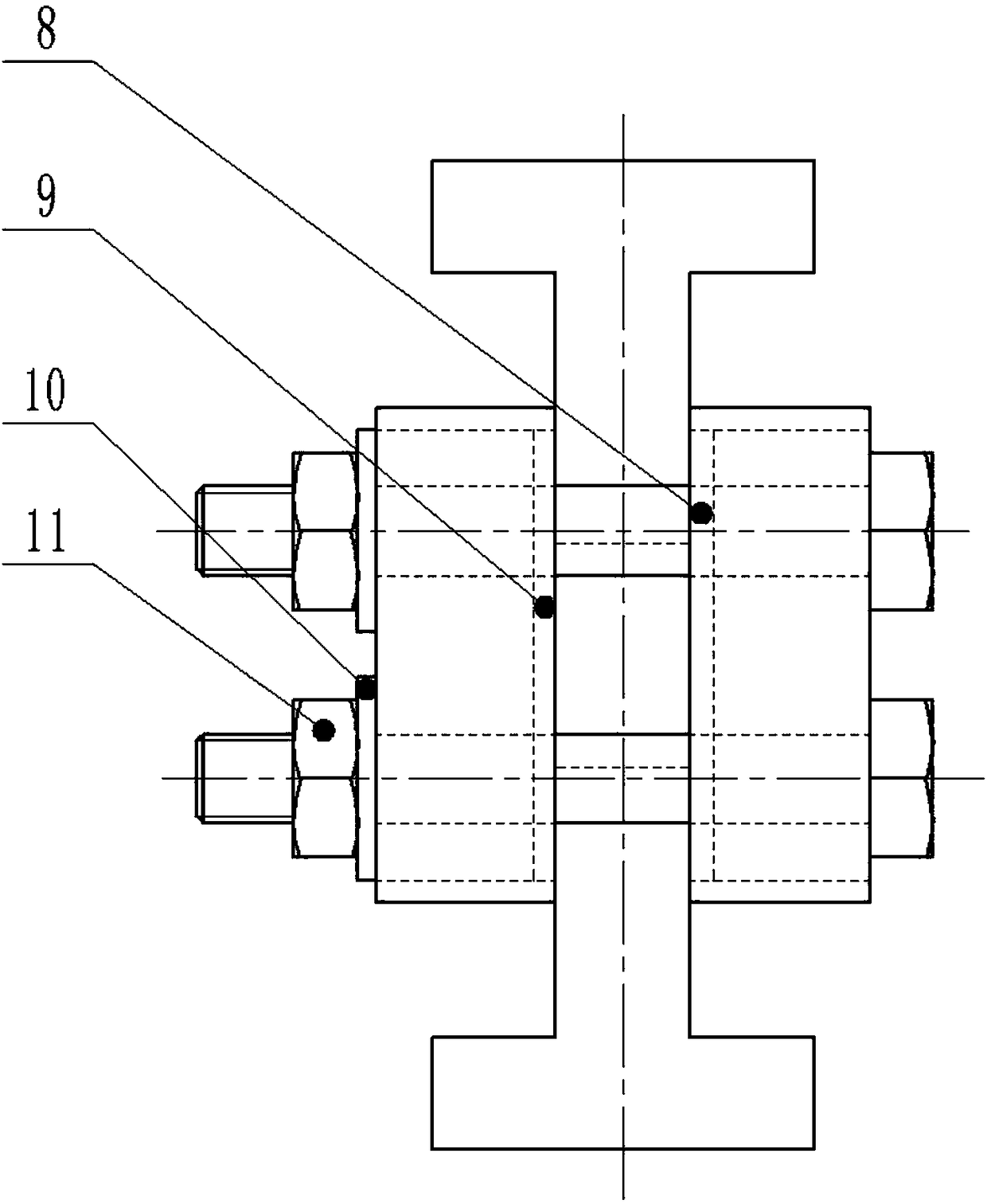

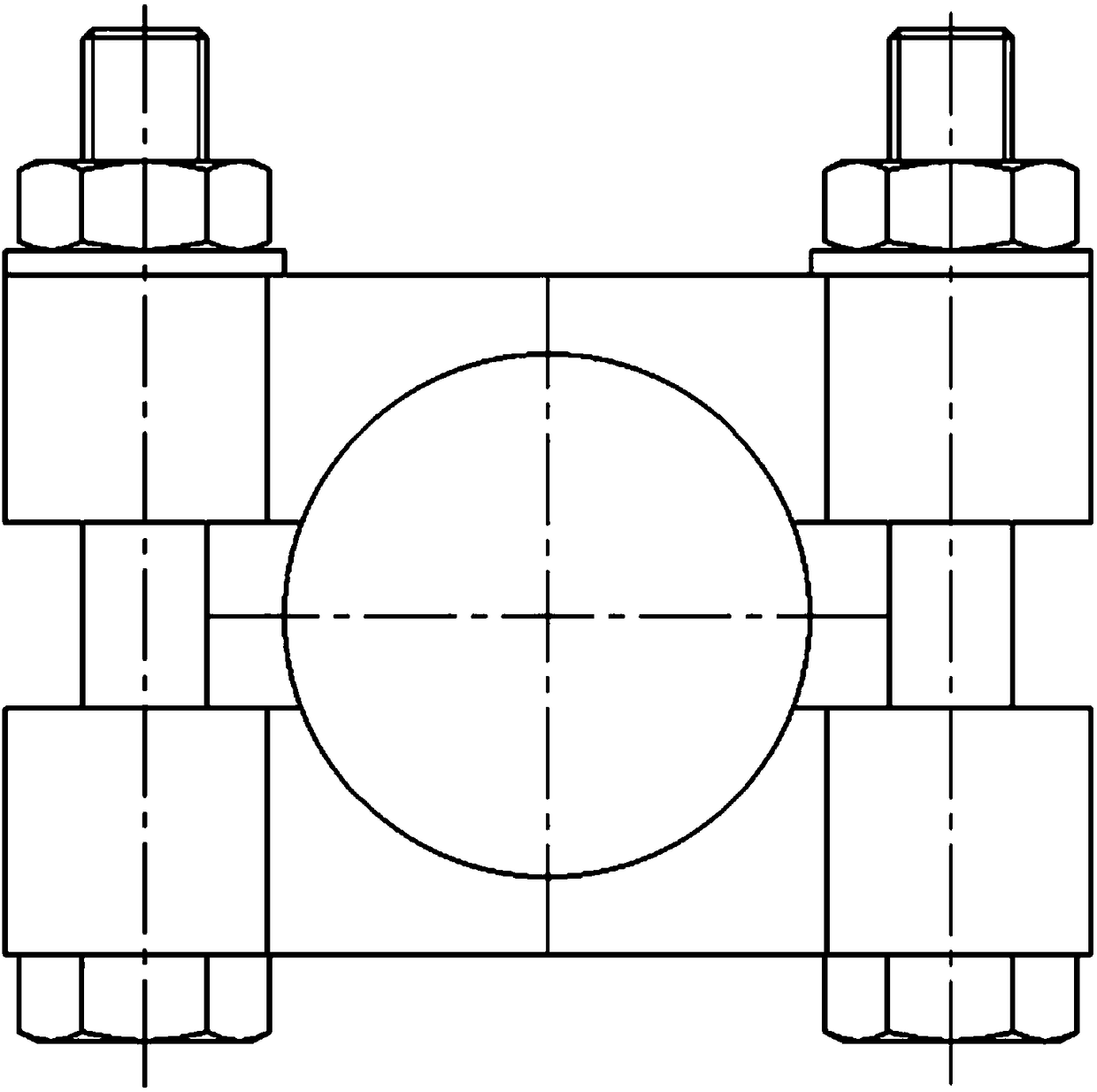

[0026] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In the schematic diagram of the present invention shown, the test 3 is a cuboid, the upper indenter 1 and the lower indenter 7 made of YG8 hard alloy steel are located at both ends of the sample 3, respectively, and the upper indenter 1 and the lower indenter 7 The thickness of the flat plate part of the sample 3 should be equal to or smaller than the thickness of the sample 3, and the width of the flat plate part of the upper indenter 1 and the lower indenter 7 should be larger than that of the sample 3. The end pad A2, the end pad B6, the side pad A8, and the side pad B9 are all made of alumina ceramics with a thickness of about 1 mm; the pads are respectively placed in the corresponding grooves of the two fixing plates 5, and combined A fixed combination plate; the fixed plate 5 is made of high temperature alloy, and the depth of the groove is not more than 1mm; in order to ensure the convenience of pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com