Full-premixing low-NOx burner with anti-explosion function

A fully premixed and burner technology, which is applied in the direction of burners, gas fuel burners, combustion types, etc., can solve the problem of uneven mixing of gas and air, and achieve the effects of uniform air velocity distribution, increased flow velocity, and sufficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

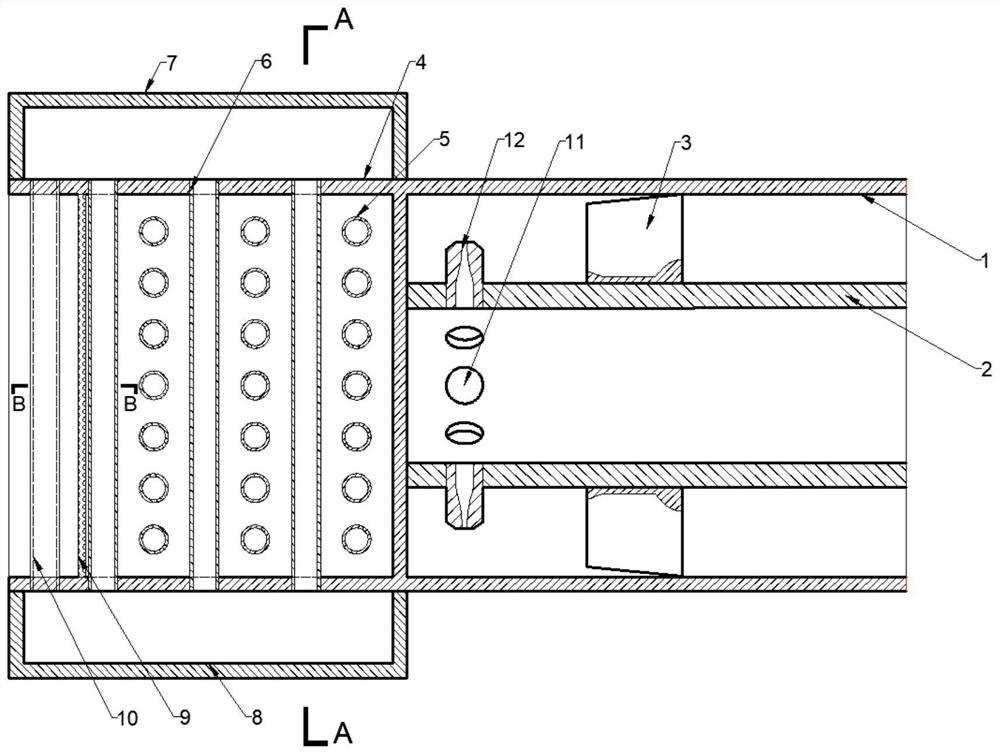

[0025] The specific implementation of the air-gas mixing device for a fully premixed burner with an explosion-proof function of the present invention will be further described below in conjunction with the accompanying drawings.

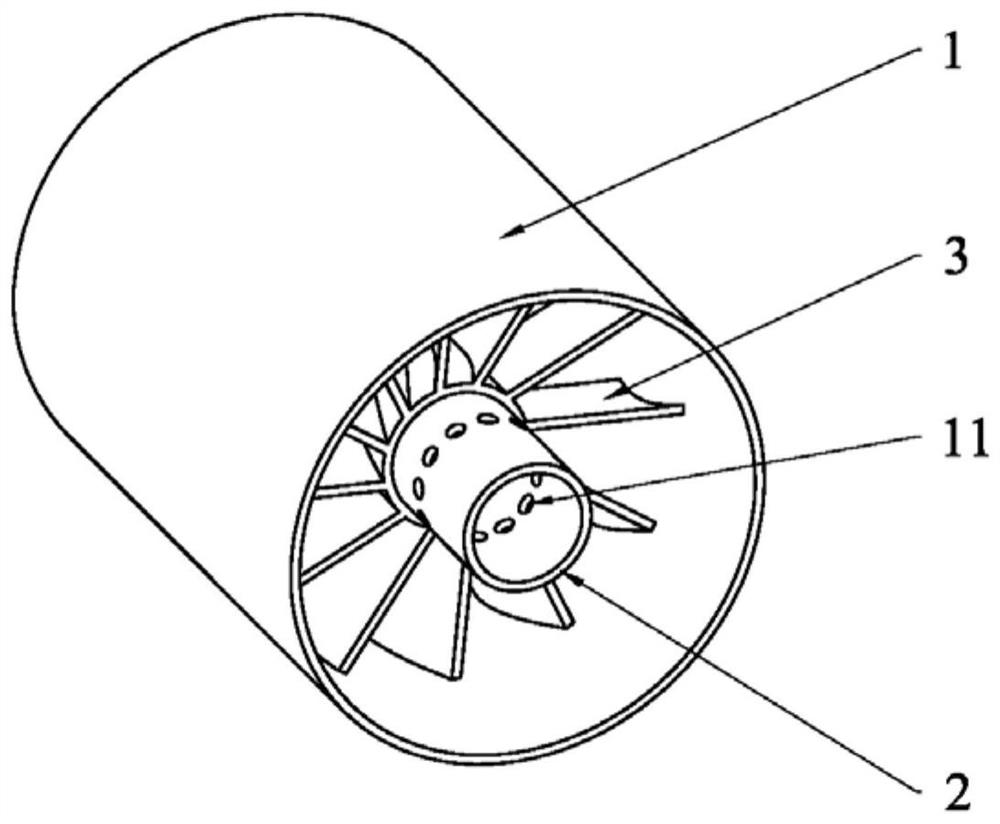

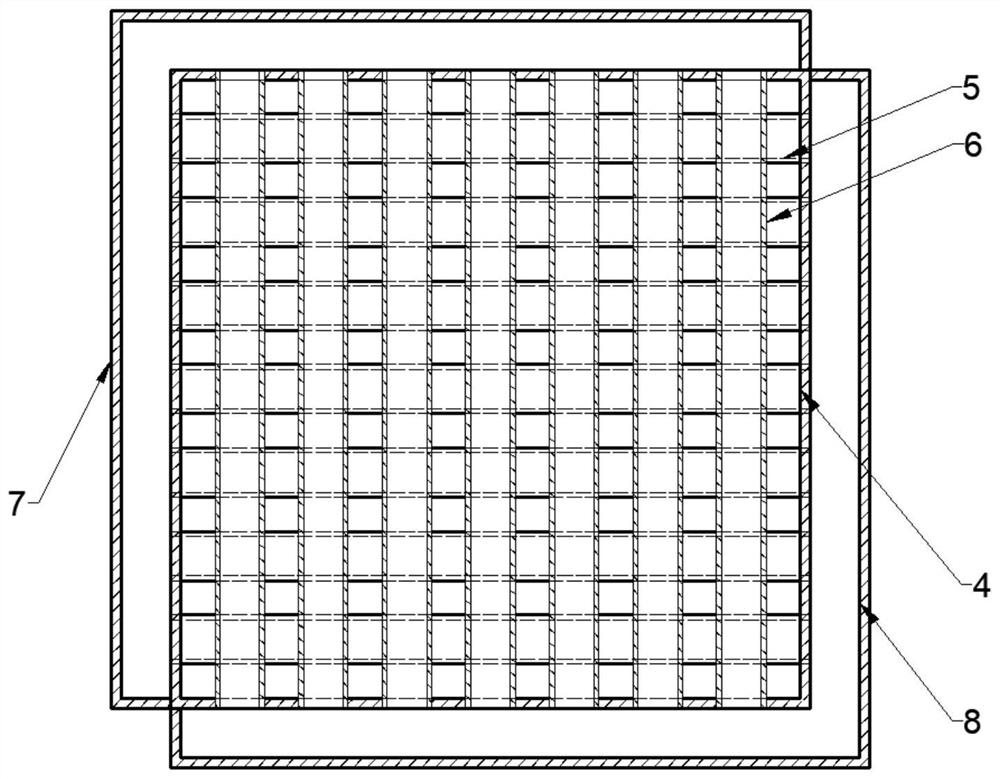

[0026] Such as figure 1 As shown, the fully premixed low NOx burner with explosion-proof function of the present invention includes an air pipeline 1, a gas pipeline 2, a swirler 3, a mixing pipeline 4, a horizontal cooling pipe 5, a vertical cooling pipe 6, an outlet water header 7, an inlet Water header 8, grid plate 9, stable combustion pipe 10, diffusion hole 11 and air nozzle 12.

[0027] The gas pipeline 2 is set inside the air pipeline 1, and the central axis of the gas pipeline 2 coincides with the central axis of the air pipeline 1; the swirler 3 is fixed on the outer wall of the gas pipeline 2, and the swirler 3 is an axial blade type swirler , the blades are evenly distributed along the circumference of the pipeline and fixed, the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com