Test special voltage equalizing ring which can be adjusted with voltage equalizing radius

A technology of radius adjustment and pressure equalizing ring, which is applied to the parts of electrical measuring instruments, measuring devices, instruments, etc., can solve problems such as low safety, accidental touch, and extended construction period, so as to improve work efficiency, remove it conveniently, Fixed and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

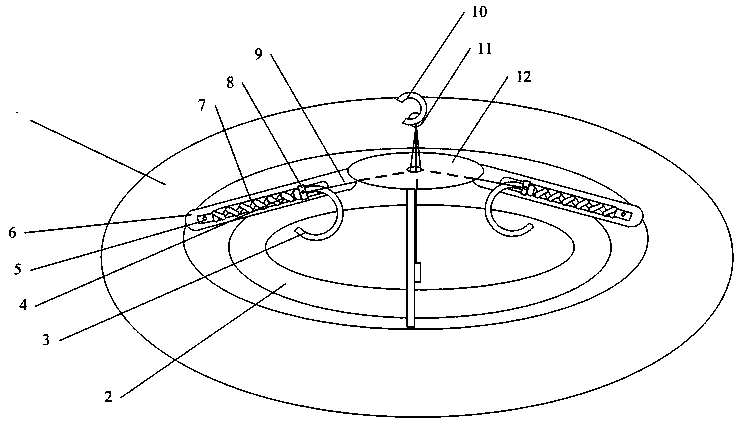

[0015] Such as figure 1 As shown, the present invention includes the test-specific pressure equalizing ring body 1, and also includes a support plate arranged inside the test-specific pressure equalizing ring 1, three support bars with the same structure size, 120 degrees to each other, and sliding tracks, three The hook 3 with the same structure and size, the pull ring 11 and the suspension hook 10, the hook 3 is arranged correspondingly to the support bar, and the center of the support plate is provided with a perforation; one end of the three support bars is connected to the shared support plate, and the other end is connected to the test The inner wall of the special pressure equalizing ring 1; the support plate adopts the support aluminum plate 12, and the support bar adopts the support aluminum bar 6,

[0016] The supporting aluminum bar 6 is a hollow cylindrical aluminum tube, the hollow cylindrical aluminum tube is provided with a sliding track 7, the hook sliding trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com