A method for preparing black silicon by atmospheric pressure discharge plasma jet

A discharge plasma and plasma technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of easy decomposition, poor chemical stability, instability, etc., and achieve the effects of low reflectivity, stable content and easy operation.

Active Publication Date: 2019-11-08

HOHAI UNIV CHANGZHOU

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But this kind of method also has the disadvantage of unstable production process, which is mainly due to the need to use H in the production process of this kind of method. 2 o 2 , while H 2 o 2 Poor chemical stability, easy to decompose

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-4

[0090]

[0091]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Login to View More

Abstract

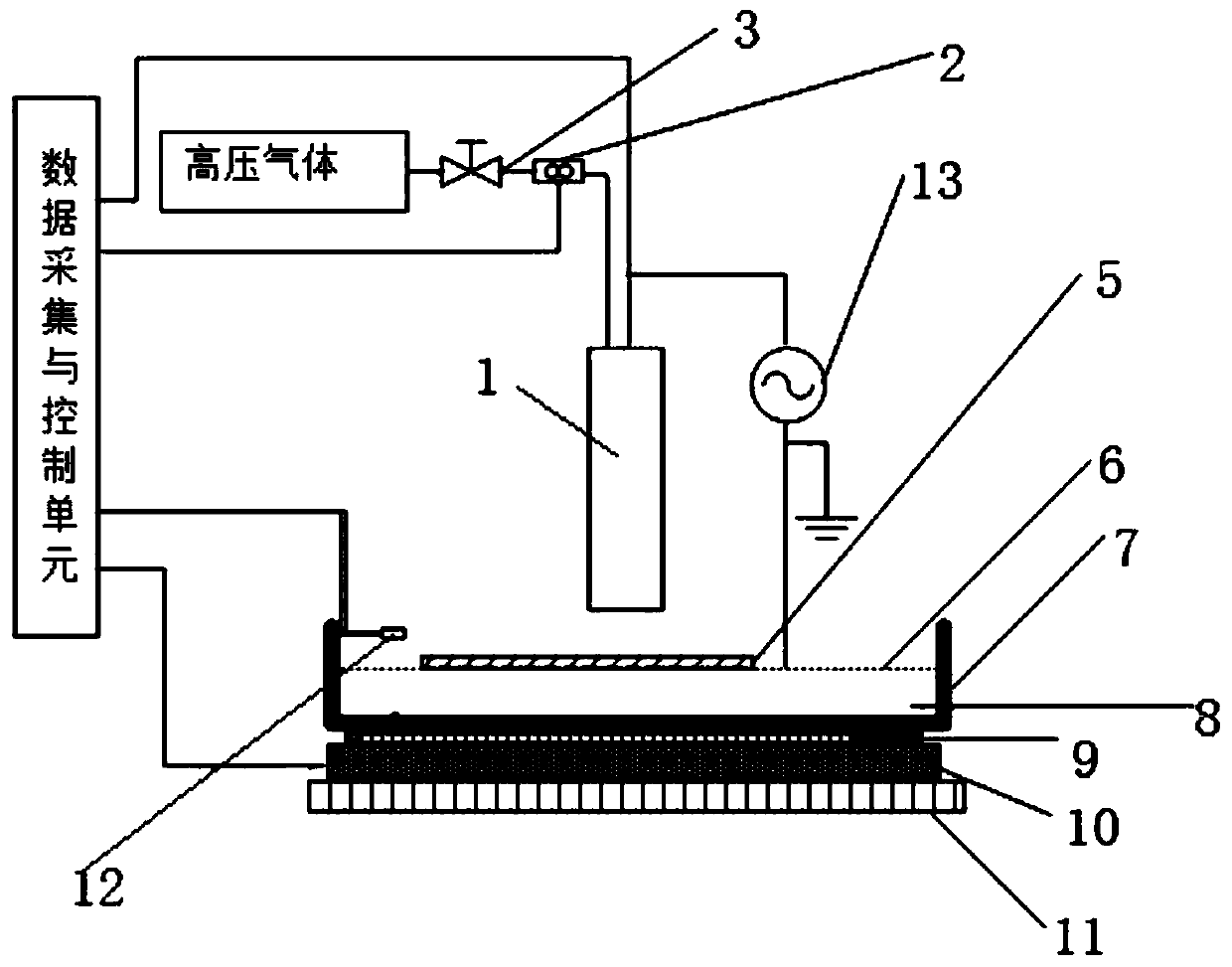

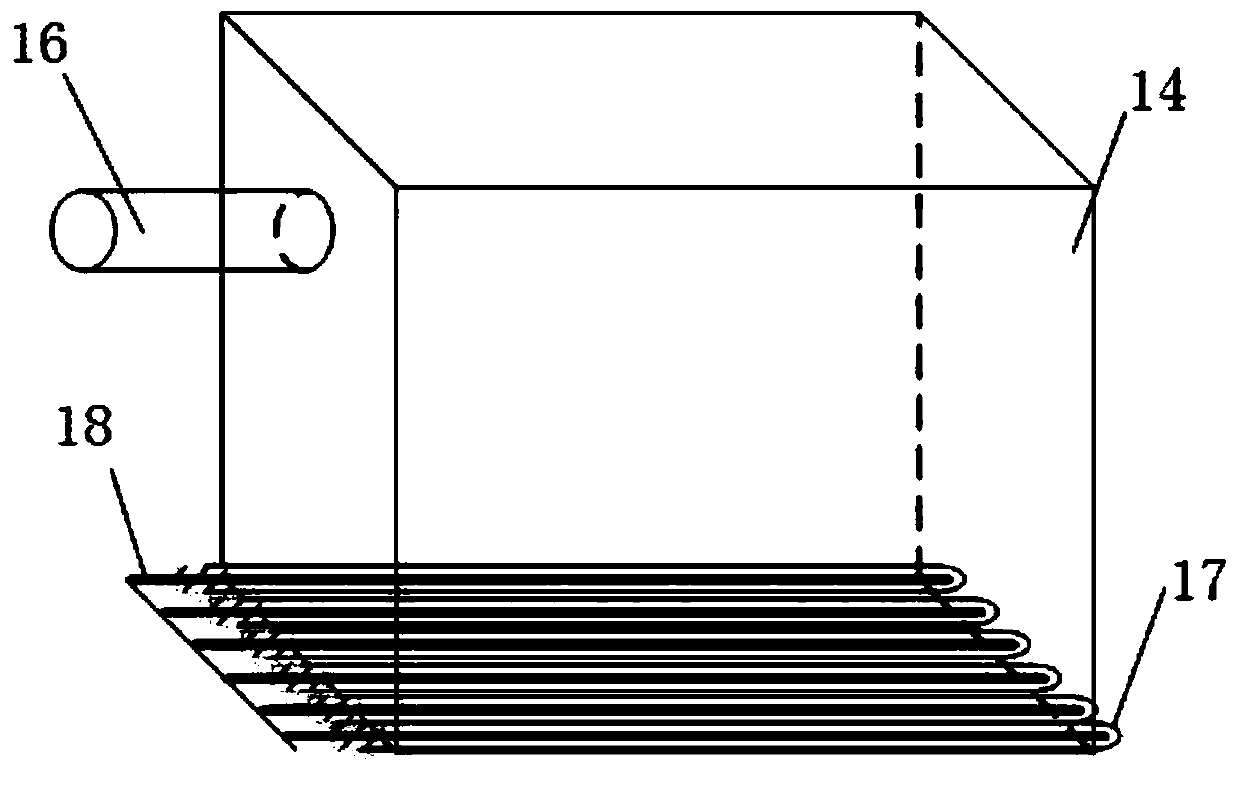

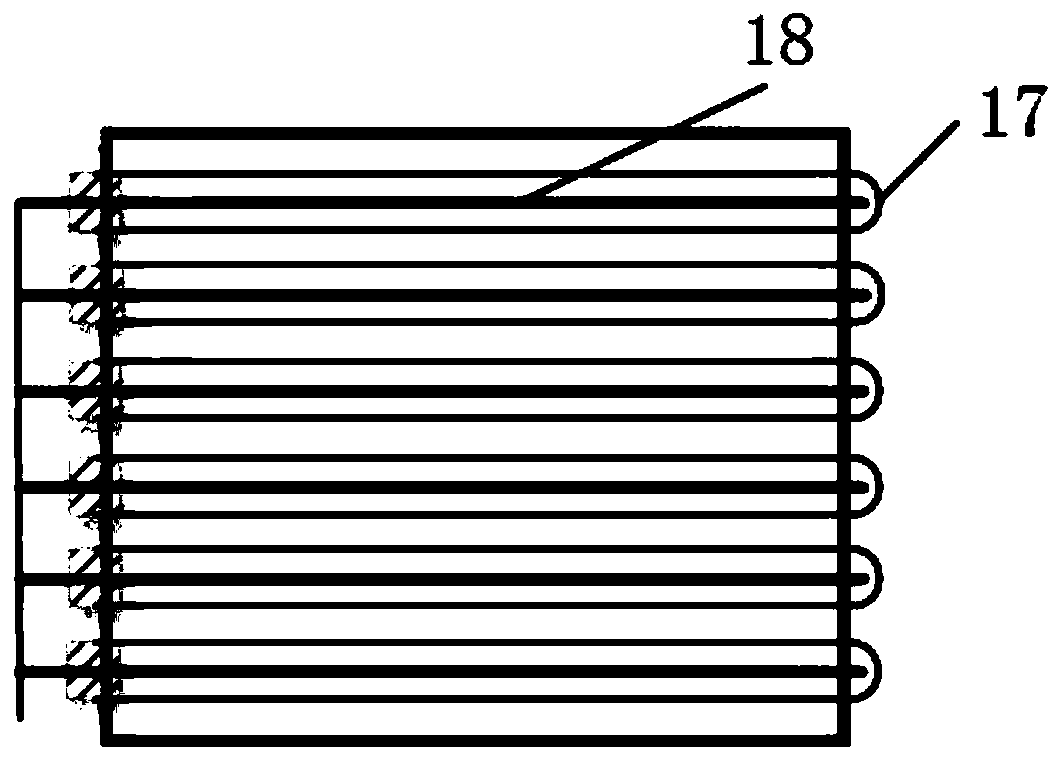

The invention discloses a method for preparing black silicon through atmospheric pressure discharge plasma jet. The method comprises the steps that a silicon wafer is placed in a plasma jet dischargesolution, and the surface of the silicon wafer is oxidized; the silicon wafer is washed in HF and ethanol solutions in order, and then is put into a NaOH solution for polishing; the silicon wafer is put into the mixture of NaOH and ethanol for texturing, and then is washed; and the silicon wafer is put into a plasma jet discharge mixed solution to prepare black silicon, and then washing and dryingare carried out, wherein the mixed solution comprises a metal salt catalyst and HF. The method has the advantages of low reaction device requirement, simple operation, low cost, normal temperature reaction, convenient large-scale production, stable generated H2O2 content, high practicability, wide applicability and remarkable economy benefit.

Description

technical field [0001] The invention relates to a method for preparing black silicon, in particular to a method for preparing black silicon by an atmospheric pressure discharge plasma jet. Background technique [0002] Due to the long-term use of traditional energy sources such as oil, coal, and natural gas, the environment has been polluted and deteriorated, and PM2.5 in the air has continued to increase, seriously threatening human health. Solar energy, as a green, environmentally friendly and pollution-free clean energy, has become the most important new energy for human beings. [0003] Photovoltaic power generation is a technology that directly converts light energy into electrical energy by using the photovoltaic effect at the semiconductor interface. Compared with traditional energy sources, the cost of photovoltaic power generation is relatively high, and it still needs government policy support, which is not conducive to the sustainable development of photovoltaic ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L31/18

CPCH01L31/1804Y02P70/50

Inventor 陈玉伟陈秉岩蒋永锋何湘朱昌平田泽刘昌裕

Owner HOHAI UNIV CHANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com